Behind the Scenes of 34m foil-assisted Baltic 111 Raven

When her owner commissioned this Baltic 111 Custom foil-assisted superyacht, weight control was paramount. Baltic Yachts was selected for its forensic approach to lightweight advanced composite construction and unique ability to combine it with an unmatched custom finish. Baltic Yachts has successfully moved the Baltic 111 Raven from her building facility at the company’s waterside premises in Jakobstad, Finland to reveal one of the most extreme yachts it has ever built.

Broadly described as a 111ft foil-assisted, ultra-lightweight superyacht, she will be used primarily for day sailing, but also undertake high-speed, long-distance passages. Not easy to categorise, this extraordinary yacht can be placed firmly in a class of her own.

Baltic Yachts was chosen to meet this challenge because of its unmatched reputation for building advanced composite superyachts to the very highest standards, including its forensic examination of systems and components throughout the build process. Add to that the company’s ability to finish yachts to a level of luxury second to none and the decision to build in Jakobstad was straightforward.

Baltic 111 Raven’s experienced owner’s project manager, Garth Brewer of A2B Marine Projects, said: “ Raven doesn’t fall easily into a category, but if I had to place her, I’d say she’s the equivalent of a high-end Super-car. The boat is primarily for pure enjoyment and the owner likes the challenge of doing something that hasn’t been done before. ”

“ He really understands the technical elements and this will be a development project which will require a measured approach,” added Brewer, who emphasised the need for incremental steps in Raven’s trials, building confidence and understanding over time as the boat reaches her peak performance .

Raven does, however, possess some distinctive features which provide more than a hint of how she might perform. They include two large T-shaped hydrofoils mounted on hydraulically controlled side-arms capable of supporting some of the boat’s displacement.

At her transom, Raven will be equipped with vertical Interceptor trim tabs to adjust fore and aft trim at speed and there is movable water ballast, carried in built-in tanks in the aft quarters to boost the righting moment required while sailing.

Designed to sail partly on her leeward chine, Baltic 111 Raven will derive her stability and lift, while sailing, from her foils, leaving her 9.3-ton fixed keel bulb and precision-engineered 5m long fin to provide basic stability. It’s also the location for a fully submerged intake for cooling water and is designed with a sacrificial zone to absorb impact in the event of a collision.

Ultra-lightweight interior of Baltic 111 Raven

Not only is Raven’s foil-assisted ability likely to deliver a phenomenal sailing performance, she is also the subject of a highly unusual study in ultra-lightweight interior design, combining the yacht’s complex all carbon construction with styling which pays homage to Baltic Yachts’ rigorous program of weight saving. Target displacement is 55 tons – just as a comparison, the recently launched, Baltic 110 Zemi displaces 95 tons.

Jarkko Jämsén, the Finnish concept designer who developed Raven with her owner and is responsible for the yacht’s styling, explained that they were keen to combine the need for weight saving with the opportunity to expose the remarkable carbon structure of the yacht to create a unique interior design aesthetic.

A key part of Baltic’s effort in the Raven project has been directed at weight saving and control. Apart from using the lightest possible carbon/Nomex combinations in the yacht’s main structures, every item, down to the last pipe clip, nut and bolt, has been assessed. The naval architects and structural engineers behind her are Botin Partners and PURE Design respectively, both at the leading edge of America’s Cup design.

“ This project undoubtedly represents one of the biggest challenges Baltic Yachts has ever embraced, ” said Baltic Yachts Executive Vice President, Henry Hawkins. “ But that is what we do – we have a long history of bringing leading edge innovation to the fore. We are surrounded and supported by a dedicated team who are led by Garth Brewer, who oversaw Visione’s construction here at Baltic 21 years ago and still keeps her on the pace. ”

Baltic 111 Raven: Experience to take on the challenge

Jarkko Jämsén emphasised the importance of choosing Baltic Yachts to build Raven. “ The company was selected because we believe it has the courage, experience and track record to take on the challenge. Calculating weight and Baltic’s well-known ability to hit displacement targets were critical. ”

For Sam Evans, project manager, and Mattias Svenlin, project co-ordinator for Raven, the challenge was to construct a superyacht much lighter than anything previously built by Baltic – yachts that were already considered light in the sphere of Superyachting. “ Mattias’ experience, creativity and flexibility, supported by a dedicated production team combined with Sam’s communication skills, have been key factors in the overall success of the build, ” added Garth Brewer.

“ This is another level entirely in terms of weight saving, ” said Mattias. To ensure as fair a hull finish as possible, a carbon mould was preferred to reduce excessive heat differences and thus distortion in the curing process. “ We re-assessed the hull coating schedule to reduce weight using light primers and filler instead of Ultra-Build to reach the acceptable industry standards – in effect coatings do the job of filler,” he said. Using this technique in a superyacht is unprecedented .”

Hull and deck construction use carbon IM fibre pre-preg, employing the highest quality fibres on the market, and a Kevlar honeycomb sandwich throughout. The owner has accepted that sailing Baltic 111 Raven at speed will be noisy so the elimination of any attempt to sound deaden represents a huge weight saving. “ But we have created an interior finish with special surfaces affecting the acoustics to ‘soften’ the noise a little, ” said Mattias. He pointed out, however, that all the adhesives suitable for bonding this material to bulkheads were compared for weight, the final choice resulting in a saving of 6kg. In terms of the Raven project that’s a big number.

100 grams off every bracket

Baltic Yachts has revisited all weight saving opportunities shaving 100 grams off every carbon pipe bracket, making carbon cable trays even lighter and switching out steel hydraulic pipework for lighter hosing which has saved 160kg. “ We’ve even reduced the weight of the shower door from 13.5kg per m² to just 2.3kg m², ” said Mattias.

Even as Raven neared completion, the Baltic build team were continuing to identify weight-saving opportunities including replacing the metal clips holding the lightweight carbon tubular accommodation framework in place. “Östen Sundelin, one of the team, reckoned we could 3D print them in a far lighter material so we went ahead and made that saving,” said Mattias. In-house 3D printing is increasingly used at Baltic to fashion custom items to save weight and optimize design, the complex titanium head of the yacht’s retractable propulsion system (RPS) mechanism being a case in point.

Lightweight interior design

Raven’s interior, conceptualized by Jarkko Jämsén, is unusually comprehensive for a high-performance superyacht of this type, but the use of ultra-lightweight rattan deck-heads and bulkhead finishes, exposed carbon and a lack of coatings help keep weight down along with Nomex cores in structural bulkheads. All the frameworks for the furniture, for example, are made from hollow carbon piping, its lightweight combining with a modern take on style guaranteed to turn heads.

The focal point of the accommodation is centered around the glazed sides of the large cockpit, dubbed the ‘bird’s nest’, which forms a type of inverted observation ‘dome’ allowing occupants to view the carbon-dominated accommodation. The glazing is in fact Perspex, which is considerably lighter than toughened glass, representing an overall saving of 250kg. It is reinforced with a criss-cross pattern of carbon mullions which gave it its bird’s nest description. Further weight saving is achieved by minimizing the amount of caulking between each pane and replacing some of it with a foam fillet.

On deck, attention is immediately drawn to the cockpit because, apart from its aforementioned aesthetics, it also converts to a semi-covered, hardtop-protected seating area. The forward section of the cockpit hinges up and aft in ‘clam-shell’ style to affect this unique conversion.

Perspex is also used in numerous deck prisms which still use a centuries-old design to efficiently illuminate the accommodation with natural light, but are vastly lighter by replacing bronze and glass with carbon and Perspex.

Spacious saloons are located fore and aft of the bird’s nest, the forward one laid out with a galley and dining areas and the aft space dedicated to the owner’s sleeping accommodation, with a large double centreline berth folding up against an interior bulkhead when the yacht is in performance mode. There’s also a passage berth or sea cabin to starboard.

It is not often one can describe a head and shower compartment as a work of art, but in the Baltic 111 Raven’s case numerous hydraulic rams mounted inside some of the complex carbon reinforcement, including the A frame taking the load of the deck stepped mast, have been exposed by inserting Perspex inspection covers. So, you can take a shower while watching the upper and lower deflector rams in action or the downhaul ram for the 7m long reaching strut, which is used to optimise headsail sheet leads!

Further weight saving has been achieved by modifying a custom bamboo seat in one of the shower/head compartments with carbon tubing made to look like bamboo, complete with its characteristic rings and a remarkably realistic painted finish.

The aft section of the yacht is largely empty, but forward there’s accommodation for four guests in two cabins and extensive crew accommodation including a captain’s cabin.

For propulsion and generating, the design team settled on a diesel-electric hybrid system for lower emissions and efficient weight distribution. It’s a solution Baltic Yachts has been perfecting for a number of years. A Swiss 130kW Phi-Power AG electric propulsion motor is located just aft of amidships and twin 80kW Yanmar generators, optimized to save weight, are located further aft. These charge two battery banks which power the main propulsion motor, hydraulic pumps and accommodation services. The drive train is completed by a retractable propeller designed with carbon blades and a titanium hub.

Beneteau Introduces the New First 30… the Planing Cruiser

Grand soleil 52 performance: new life to the myth, nautor swan merges with sanlorenzo group, royal huisman project 410, ready to roll the hull, live your passion, subscribe to our mailing list.

- Forums New posts Unanswered threads Register Top Posts Email

- What's new New posts New Posts (legacy) Latest activity New media

- Media New media New comments

- Boat Info Downloads Weekly Quiz Topic FAQ 10000boatnames.com

- Classifieds Sell Your Boat Used Gear for Sale

- Parts General Marine Parts Hunter Beneteau Catalina MacGregor Oday

- Help Terms of Use Monday Mail Subscribe Monday Mail Unsubscribe

What about Baltic boats?

- Thread starter Old Sailor 2

- Start date Dec 3, 2013

- Hunter Owner Forums

- Ask A Hunter Owner

Old Sailor 2

As you folks know I currently own a Hunter 42 Passage which we love for the layout and we are able to sail her quite competitively BUT I am concerned that despite Hunter's original design having the Passage being a blue water boat my reading tells me it may not be which certainly is a point of debate by many. In researching I have read about Baltic boats as being a "cruiser/racer" similar but with more creature comforts than a C&C. So let's reopen the debate. I have my Hunter Passage about the way I want her with upgraded electronics etc but is it advisable to change to a Baltic 43? I know many plan to sail the blue water and few actually achieve that goal. But a blue water boat can be used for coastal cruising but can a coastal cruiser be used in the blue water? Ah the questions........ Thanks as usual. Sandy

The Baltic 43 is a beautiful boat and can take you anywhere. Designed by J/V and built in Finland to a very high standard. If it's in your budget then why not? Life is short.

how would you describe a blue water boat as compared to a coastal cruiser?... we know that a light daysailer or weekender is not normally considered a coastal cruiser, but a boat that is built for and is set up and maintained as a coastal cruiser would imply that you should be fine for running down the coast where you can get into port sometimes, or a trip to hawaii or alaska.... or across the canal to the Caribbean/Atlantic side... bahamas.... but probably not cape horn or the southern ocean... there will be many different opinions im sure... so, is it a different boat, or is it how you have your boat set up?... is it a boat that can go a couple of months or more out beyond sight of land without needing to stop anywhere for provisions?... are you needing a boat that you are going to sail far south into the southern ocean?... in my opinion, providing the hull is strong enough (and im sure the H42P is), almost any boat can be set up as a bluewater boat... but the available space inside the boat will dictate the amount of provisions that can be carried for extended voyages without stopping for water and groceries.... and in the same way, a good solid blue water boat can become de-rated into a coastal cruiser thru neglect... it has to be set up right and maintained afterwards.

centerline said: how would you describe a blue water boat as compared to a coastal cruiser?... we know that a light daysailer or weekender is not normally considered a coastal cruiser, but a boat that is built for and is set up and maintained as a coastal cruiser would imply that you should be fine for running down the coast where you can get into port sometimes, or a trip to hawaii or alaska.... or across the canal to the Caribbean/Atlantic side... bahamas.... but probably not cape horn or the southern ocean... there will be many different opinions im sure... so, is it a different boat, or is it how you have your boat set up?... is it a boat that can go a couple of months or more out beyond sight of land without needing to stop anywhere for provisions?... are you needing a boat that you are going to sail far south into the southern ocean?... in my opinion, providing the hull is strong enough (and im sure the H42P is), almost any boat can be set up as a bluewater boat... but the available space inside the boat will dictate the amount of provisions that can be carried for extended voyages without stopping for water and groceries.... and in the same way, a good solid blue water boat can become de-rated into a coastal cruiser thru neglect... it has to be set up right and maintained afterwards. Click to expand

One Thing To Watch Closely ...is the teak decks and cockpit. That is assuming you are buying used. A well-known actor who had his next to mine for years spent over 20K to have just his cockpit done, and that was ten years ago when the boat was maybe 15 years old. And, it needed the deck done next. The boat itself looked pretty bullet proof although the hull shape was sort of IOR-ish although modestly. Some of the rigging and interior bits and were hard to obtain in the states. He single handed sometimes but it looked far better laid out for a crew in winch and running rigging layout. She carried a high aspect main with big headsails. So, those are a few of the things to look at and consider as you check out these beautiful boats.

Barnacle Bill

CE Category Indicates the conditions the boat has been designed for and how many passengers it can take. There are four main categories A Ocean B Off Shore C Inshore D Sheltered Waters The number indicates the number of passengers the boat was designed for. eg A/6 is an Ocean going vessel that can accommodate 6 passengers. This all has to do with how well the boat was built to withstand the A-D categories. Believe me, there are a number of ways to build a boat and there are certain criteria for each. Hull to deck joints for example are many.

Old Sailor 2 said: BUT in my opinion a blow 5 miles off the coast like a Santa Anna blow is just like a blow a thousand miles off shore. Click to expand

Baltic and Hunter completely different boats....while I loved my 42, could I afford moving up to the Baltic, would be a no brainer. I would even drop back to a Baltic 38, 8-10 years older than my 1991 and likely be happy!!

KD3PC said: Baltic and Hunter completely different boats....while I loved my 42, could I afford moving up to the Baltic, would be a no brainer. I would even drop back to a Baltic 38, 8-10 years older than my 1991 and likely be happy!! Click to expand

stirring the pot here but what is this drivel about certain boats not being blue water capable, tell that to dove...setup and PLANNING are key, i just completed a costal delivery in a 37.5 hunter where the owner insisted on slowing the boat down to keep on schedule. it resulted in a very unpleasant ride for the conditions, had they been worse the ride would have been dangerous. the rating system has definitely resulted in some "a" boats that are definitely not "a" boats. as a caveat to that tho an "a" boat can definitely be an "a" boat if its rigged out then treated properly in addition to planning a trip around the boats characteristics, specifically im going to pick on fast olson for the "They have the design, construction, and durability for sustained time off shore." comment, no matter what you shop for theres nothing that will fit this bill in its truest sense, whats the point, if you are going to spend "sustained time offshore" then get you an open 60 and circumnavigate, if you are going somewhere stop screwing around out there and find safe harbor, if you plan properly and choose a well constructed boat and operate it properly then you will be a blue water sailor, if you however get an oyster 60 and get lost in the southern ocean and dont realize that you are sailing into a squall with growlers all around you in 30 foot waves off cape horn then you have defeated the purpose of your "blue water" boat and the guy hopping islands in the bahamas and wintering in mexico or the gulf coast on his 28 oday is more of a blue water sailor than you. after a certain point its about the sailor/owner/operator/capitain role that we have to fill and not the boat that is the problem. get a flika go to key west and cross the atlantic to gibralter then reconsider the swan and tell us what you have discovered about what you want and what you need.

Rufus, Any safe voyage requires some part of four ingredients: 1) Planning (what you think of beforehand, and prep) 2) Skill (sailing ability, how YOU react in real time) 3) Boat (scantling strength, watertight rudderbox, overbuilt rigging, etc) 3) LUCK The more you have of the first 3, the less you need of the last. The one part that is not skipper related is the basic BOAT, and the more built-in blue-water capabilities it has, the better off you will be. There is no escaping that. I'm not talking about the things you can add, like more water tanks. I'm talking design and construction. Sure you can circumnavigate the world in a coastal boat. But frankly it would take quite a bit of LUCK to make it. How many times would someone have to try before it ended badly? A LOT more that it would statistically in a Baltic. There is a reason for that.

statistically yes, this is shown in ocean racers, they build the boats and spend lots of time in the blue water, my point is that statistically the people that want to cross blue water will do one of two things. 1) buy a boat and do it (prep, lifestyle changes, planning, gathering knowledge.) 2) pine away about number 3 on your list until they decide they're too old and frail to do it then get mad and start screaming about how stupid everyone else is for not having the maltese falcon built to cross the gulf stream. (im exaggerating to make a point)

You should have confidence in the boat you want to take offshore, whether it’s a Hunter or Baltic, Swan, or Catalina. It’s more the captain more than the boat, in most instances that make the difference how you fair offshore. Read the blog of Sequitur http://www.sailblogs.com/member/sequitur/ he took that Hunter into some terrible weather down by the Falkland’s without a problem. He sailed from Vancover to Florida around the Cape.

So does anyone know the CE rating for the 92 Hunter 42 Passage?

most of the large and medium hunters are A rated

Marco Garcia

a young french couple sailed their 33 ft around the world for 2 years and stopped at Annapolis last June. I asked them what was the worst time during their circumnavigation, and they both agreed that the storm they went through sailing down the Potomac river going from Washington DC. to Annapolis was the only time they could not control the boat.. because of the wind gusts.... They even mentioned how nice the Indian Ocean crossing was compared to that.... They mentioned that lots of twenty some footers sailboats were ocean sailing everywhere.... Agree with the previous comments.. blue water boats are all the ones their owners take sailing accross the ocean....

There are some tried and true definitions used by boat designers and marine insurance underwriters that generally categorizes boats as to their usage - namely 'scantlings rules' or what broke or fell apart and then sunk under what conditions and most importantly what was the underlying 'strength' of the boats that survived in such conditions vs. those that didnt. Scantling rules have been effect since Mr. Lloyd (London) was a pup, such is the foundations and constant evolution of marine design and the marine insurance industry. The historical record of scantling rules is long and detailed; many of the 'smiley faces' you see on nautical charts locates a fix on those that ... 'didnt stand up' to the scantling rules. Offshore boats. The nominal definition of an 'offshore or open ocean boat' is one that is built to 3 to 4 times the strength needed to 'survive' the strongest storm normally encountered. The historical scantlings of such boats has proven itself over hundreds of years of accumulated data says that an open ocean boat should be to this level if it has a good chance to survive the 'usual' unexpected. This discounts entirely the skill of the captain or crew, the fancy gizmos, the 'modern construction', etc. as all of these aspects are subject to capricious actions of crew, materials, craftsmanship, etc. Being 3 - 4 times stronger than needed also insures that the rigging and other metallic components -usually stainless steel- does not become 'embrittled' and fatigued leading to sudden catastrophic failure - ie. without warning. Stainless steel, the metallic material of much of the modern boat construction, as rigging, etc., easily 'fatigues' due to the constant load cycling encountered in the open ocean. Typically 300 series stainless will be VERY prone to failure if the material is repetitively stressed beyond 30% of its ultimate (breaking) tensile strength - usually 1 million load cycles at above 30% usually results in FAILURE; keep that maximum stress below that 30% value and you 'may' have a rig that lasts 'forever'. Fiberglass acts in the same way; the US Navy has 100s of documents highlighting the stress values and the fatigue characteristics of fiberglass. The caution here is: dont think NEW will keep you secure. What will keep you secure on the open ocean where the impact stresses are constant and additive is: Scantlings History of the design - your designer built it that way on purpose, and your insurance underwriter insisted on it or they wouldnt insure you. Coastal designs. Coastal designs are built to a scantling rule of approx. 2 times the maximum strength needed. 2 is less than 3. Above 3 three, youre statistically safe from the boat falling apart due to constant repetitive / cyclical stress. Less than 3 your chances of 'not making it' are higher. Repeat - most 'costal designs' (aka - most 'production' boats) are built to a scantling rule that is not up to par for the long term stresses encountered on the open ocean for long periods of time. Not that you cant sail around the world in a 'coastal' design, not that you cant do long distance sailing or island hopping; but, statistically speaking and from historical scantlings perspective, youre going to have a much higher chance of NOT 'making it' than if you were in a boat built to offshore scantlings ... at an overall inbuilt factor of safety of 3 or 4. Coastal designs are usually at near a design safety factor of only 2. Inshore design. Factor of Safety is ~ 1.5. 1.5 is 'half' of 3. 'Nuff said. "Modern Design" and "new" Just take a good look at the boats that are in 'charter service' after only 1 year. Just because a boat is 'new' does not mean strong or 'proven', ... remembering the keels that were falling off of expensive Bavarias and the many spade rudders falling of the Jeanneaus and other french boats, etc. 'Proven' is a word that means the 'scantling history' as accumulated over time is OK or that most successfully completed long distance passages were without incident or failure of materials, design, etc. Fatigue and its subsequent catastrophic failure of materials is what mostly sinks and breaks apart boats, especially in boats that werent designed for the service intended. 'Proven' is far vastly better than 'new', or 'modern'. "Proven" means well defined and successfully scantling history. When in doubt about a boat, any serious boat, ...... contract with a reknown marine designer/architect. ;-)

Jackdaw said: Some one else said 'any boat can be made into a blue water boat'. That's pure rubbish. Our First 36.7 is 'A" rated, and she would NOT be my first choice to cross the Atlantic. Click to expand

for a good quick look at 'scantling history' why not check out what is actually 'out there' that is older than say 20 years and actively cruising during that lifespan. i can tell you ive heard it from many mouths that the large portion of them are oday (28 usually) hunter (cherubini 27 30 and 33 usually) pearson (30 10meter and a smattering of others) grampian (30 ish models) moody (32 to 42 models) and a few others, the large majority tho are listed. this is from people ive met that probably have millions of cumulative miles all over the planet but mainly equatorial locations. many tho had to have traversed some snotty stuff. so i go back to my original quote, 2 kinds of people when it comes to cruising blue water, those that get one that is a good platform and make it ready, and those who pine about yachts with insane price tags that wont be able to do the job off the showroom floor no matter how you cut it, ive never seen a yacht that had it all that wasnt a racer, there is always something that needs to be done, why not start with a worthy foundation of a boat (i picked a 33 hunter 1978) and make it what you need to get the job done. for the record i agree with the two previous posts, the point is that baltic boats are nice, sure, but you shouldnt start with the attitude of "if only i had that baltic... then i could do blue water", that leads to the path where you find yourself old and decrepit, owning your baltic and saying, "gee, i got this baltic but its just not quite right.....if i had a swan then....mabey then... i would be safe to cross that big blue pond." if you want a baltic cuz it appeals to you thats admirable, they're beautiful boats, but dont fool yourself or anyone else that there is a mark somewhere "up there" that means you have finally arrived at a blue water boat. find your boat, the one that speaks to you and is a part of who you are as much as you are a part of it, and make it your blue water boat.

As I write this, I am clearly out of my depth, so I will just pose some questions. 1. From my reading, it appears that relatively few blue water sailors or boats are actually lost at sea due to catastrophic failure of the boat. That is very distinct from the much greater number that may have to limp to a foreign shore where very expensive parts are ordered and laid in while the crew waits for them. My guess is that engine issues and standing rigging constitute the most frequent offshore issues, and hull failure or delaminations very rare? 2. If the above is true, it seems like it would be possible to make a coastal cruiser into a blue water boat at considerable expense doing many of the things suggested by Berman in his Outfitting the Offshore Cruising Sailboat . I guess this raises the question whether it is better [cost effective and/or quality] to buy a boat that came from the factory with most of these improvements, or to have them added to ones own specifications. 3. Some part of this debate focused on Jackdaw's observation that the better the boat and skipper, the less one has to rely on luck. As a novice, I look at luck as how forgiving my boat will be when my inexperience and stupidity puts me in a tight situation. Anyone who spends a great deal of time offshore is destined to make some mistakes, or fall victim to the mistakes of others. I suspect that's where the build of most boats will have their chance to minimize the impact of the error of our ways.

- This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register. By continuing to use this site, you are consenting to our use of cookies. Accept Learn more…

Half a century at the cutting edge

Fifty years ago in Finland five young men shared a controversial idea and an ambitious plan. They quit their jobs at Nautor and set out to create a new style of offshore cruiser racer – lighter, stiffer and faster than almost anything else on the market.

‘We just got together one day and the idea came up,’ says Per-Göran “PG” Johansson, one of the five founding fathers of Baltic Yachts back then and still one of its directors today. ‘We were not alone thinking “light is better” but most boatyards and naval architects favoured heavier designs. Some of our competitors published studies for marketing purposes arguing that heavy was better. One of their claims was “heavy does not stop in waves due to the inertia of the mass”. Another was “the client gets more kilos for his money”. We remained convinced and carried on with our lightweight, hi-tech way.’

History soon proved Johansson and his colleagues to be absolutely correct and the company they founded became a world leader in the production of large, high-performance sailing yachts.

Before any of it could happen, first they had to clear a patch of pine forest at Bosund near Jakobstad and build a shed in which to do it.

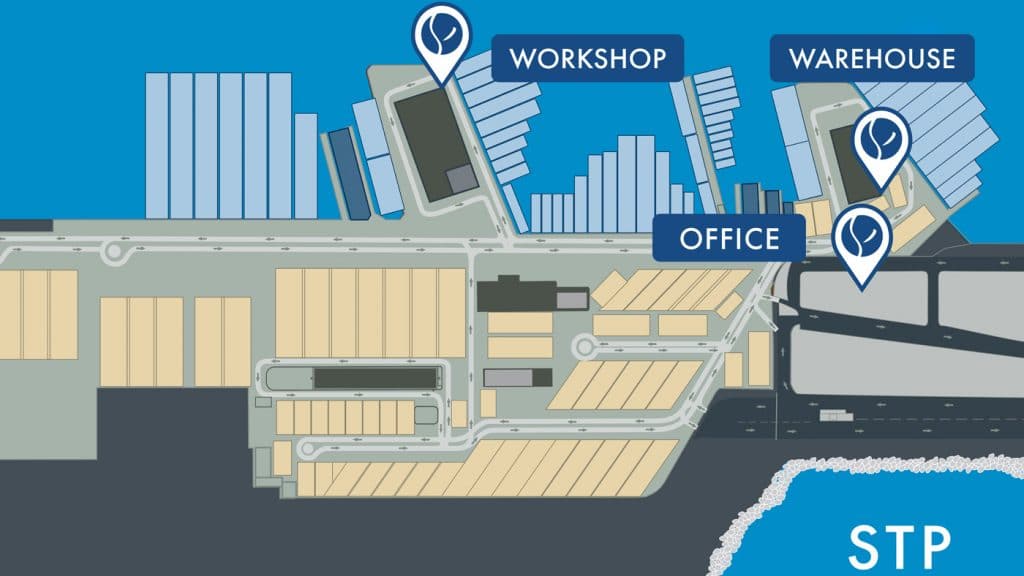

Still in use as a joinery workshop, that first shed is finally about to be decommissioned along with the whole facility that grew up around it. This year, Baltic Yachts is moving all operations to Jakobstad where a new state-of-the-art building will more than double the size of its existing waterfront location.

There’s a world of difference between the series-produced Baltics of the 1970s and the full-custom superyachts that have become the yard’s primary focus alongside its ongoing small-series, semi-custom production.

However, from the first Baltic 46 Diva (now Queen Anne) all the way to its current projects via some of the most advanced sailing yachts in each of the last three decades, the core DNA is arguably unchanged.

‘Baltic Yachts is still very much true to its original values,’ Johansson says. ‘We started as a series production yard but with more flexibility built in than most competitors, using hi-tech methods to achieve better sailing performance and handling characteristics. With time we moved over more and more to full custom projects, which required changes in our approach.

‘The projects became more individual in concept, in styling and in materials and methods used.

In that process you lose some of the things that originally earned your company its reputation. However, even our cruising projects have been very hi-tech and in that sense they’ve followed our original philosophy, “lighter is faster and better”. Some of the high-performance projects challenged us to take technology much further, increasing our know-how and potential.’

Eagerness to embrace technology prompted the founding of Baltic Yachts in the first place. Johansson was project manager of the Swan 65 when he tried and failed to convince his managers that it could be built lighter, stiffer and better using sandwich construction with unidirectional fibres instead of a single laminate with woven rovings.

The five who left Nautor – boatbuilders Jan-Erik Nyfelt and Nils Luoma, purchasing manager Ingmar Sundelin, designer Tor Hinders and Johansson – became the nucleus of Baltic Yachts.

Baltic Yachts – major milestone boats 1974-2022

1974 Baltic 46 Ahead of its time: tank tests, sandwich construction, unidirectional fibres, balanced spade rudder, epoxy bonded teak deck…

1977 Baltic 39 Most popular model, 74 in six years. From 1980, one of the first yachts to have computer-generated VPP

1979 Baltic 51 Notable for interior design innovations. First double-berth cabin under an aft cockpit, slanted bulkheads for optimal use of space

1982 Baltic 80 Midnight Sun Baltic Yachts’ first maxi racer and one of the first maxis with full glassfibre composite construction.

1985 Baltic 43 Bully The first offshore sailing yacht in the world built entirely with epoxy resin

1996 Baltic 67 Aledoa The first cruising yacht built entirely in pre-preg carbon

1996 Baltic 87 Anny First Baltic with a lifting keel, complex hydraulics and push-button sail controls

1997 Baltic 70 Vittfarne First Baltic yacht to combine classic appearance with hitech construction and modern hydrodynamics

1997 Baltic 70 Loftfari The first yacht with a fully fitted interior built entirely in pre-preg carbon and Nomex honeycomb, all invisible under the teak veneer finish

Baltic 78 Super Baltic 5 Canting keel with its entire mechanism under the cabin sole; 3.5kts faster than the same yacht with a fixed keel

2002 Baltic 147 Visione The first superyacht capable of planing at 30 knots. Packed with unique innovations, ultra-light displacement (105T) and almost literally no expense spared

2003 Baltic 141 Canica A very complex build and fitout with hi-tech materials, construction techniques and systems. The first Baltic ‘super cruiser’

2011 Baltic 197 Hetairos Largest carbon composite sailing yacht in the world at 221ft LOA. Classic look, superb finish. Hi-tech build and hydrodynamics

Baltic 175 Pink Gin The largest full carbon sloop in the world to date. Unique fold-down, through-hull platforms in the saloon and owner’s suite

2019 Baltic 142 Canova First DSS foil on an ocean cruising superyacht. First hybrid drive with full regeneration. Advanced composite engineering. A giant leap into the future

2022 Baltic 68 Pink Gin Verde First Baltic yacht built with 50% flax fibre. Advanced electric/hybrid propulsion, super efficient systems

‘They had a strong belief in themselves, courage to swim upstream and test new ideas,’ Baltic Yachts’ marketing manager Elisabet Holm explains. ‘They all had a passion for boats, a strong driving force to learn new things and research technology, and they were always ready to meet new challenges.’

The original Baltic 46 was far ahead of its time. At a time when nearly all new designs simply relied on the naval architect’s eye, experience and intuition, several different hull models were tank tested across a range of speeds, at various heel and leeway angles before the design of the 46 was finalised and only then was it built. It had a balanced spade rudder and solid rod rigging, which were then used only on hi-tech racing yachts and its teak deck was laid with epoxy resin. But the hull laminate itself was the key innovation.

‘In those days most yards building larger yachts used woven rovings with fibres bent, not straight, hence not structurally optimal and they also resulted in resin concentration,’ Johasson explains.

‘You could see the roving patterns on the surface, due to resin shrinking, so before applying the rovings they used several layers of chopped mat, which has very low structural value, especially on larger yachts, but added a lot of weight.

‘We used a very thin surface cloth and the rest of the laminate was unidirectional fibres, oriented in the direction of the stresses and perfectly straight, hence stronger and stiffer.

‘The fibres we used did not create resin concentration so there was less print-through on the hull surface. Unidirectional does not build up thickness like woven rovings so we used them with a core material in sandwich construction. This achieved much higher panel stiffness than a single laminate and gave us more flexibility for panel sizes.’

End grain balsa was the core for the 46 but Baltic soon switched to foam cores with a variety of densities and strengths. Carbon fibre was used from 1979, initially in rudder posts, beam tops and to reinforce high-stress areas of the hull where extra stiffness was needed. As stabilised foams for high-temperature cures and then Nomex for pre-preg carbon construction became available, Baltic pioneered the use of those materials.

Baltic Yachts’ early achievements belie the fact that it faced strong headwinds right from the start. 1973 was a bad year to launch a new brand of sailing yachts, with the global oil crisis looming.

The yachting industry as a whole was hit hard and by 1977 Baltic had to seek outside investment to stay in business. Ironically that same year saw their first major commercial success, selling 12 Baltic 39s at the Hamburg Boat Show, which was unheard of at the time.

Hollming, a Finnish shipbuilder, acquired Baltic. Two of the founders, Nils Luoma and Ingmar Sundelin, quit but the takeover turned out to be a positive move. Hollming provided stability and investment to help Baltic grow. A huge production hall was built, funds were provided for new model development and marketing.

An unusual aspect of Baltic Yachts that undoubtedly worked in its favour was the dual role of Johansson. It’s rare that the technical guru of a major boatbuilder is also its head of sales and marketing, yet he combined both jobs with great success for 40 years.

Even now, though officially retired, he still frequently offers a guiding hand in the development of new projects and the current EVP, Henry Hawkins, describes him as ‘an unbelievably useful sounding board and wise head’.

Baltic’s in-house designer Tor Hinders made his mark by changing the way boats are fitted out down below. His stand-out innovation, which was met with hostility when introduced in 1979 on the Baltic 51 but has since been copied by almost every sailing yacht builder in the world, was to put a double-berth cabin under an aft cockpit.

Another key factor in Baltic Yachts’ early success was its partnership with the Canadian naval architects C&C Design, whose chief engineer Rob Ball was among the first in the industry to start using computers. From 1980 he supplied VPP – polar curves and tables of numbers – for the Baltic 39, 51 and 37, with detailed instructions on how to use them. Despite being generated by 2D computing (as 3D models were not yet available), Johansson says those first VPP numbers were accurate and useful.

The yard was quick to develop its own computing expertise. ‘As soon as programmable calculators and then the Epson HX-20 computer became available we saw their potential and started to use them,’ Johansson says. ‘There was no software so we did our own coding.’ By the early 1980s they were already using these tools for displacement, flotation and trim calculations, laminate design and rating optimisation.

A huge quantity of data has been compiled since then and the initially simple programs have evolved into a sophisticated suite of software that enables the technical team to make extremely detailed weight and load calculations for the hull and rig of any new design, study engine power, prop pitch and range for electric and conventional propulsion systems, and much more. The yard has never had any ambition to design its own yachts, but is quite often asked by clients to do preliminary studies before a naval architect is appointed.

The 1980s were the peak of series production but Baltic Yachts but they also began pushing the boundaries of performance with custom builds with more scope for creative technical development.

‘A series production model is always to some degree a compromise,’ Johansson says. ‘On custom projects you can take things much further. For very knowledgeable clients looking for performance we have taken things to the edge.’

The 80ft Midnight Sun was one of the first maxis with full composite construction, launched in 1982. ‘The forward part was a large, empty sail store and we used specially designed longitudinal bulkheads and framework in the upper corner between hull and deck to create the required stiffness,’ Johansson recalls.

The Baltic 43 Bully was the first offshore yacht built entirely in epoxy resin, in 1985. In technical terms this was a spin-off from an earlier R&D project, developing ultra-strong vacuum-infused sandwich laminates for a Soviet deep-sea submarine, which ruffled diplomatic feathers when the Americans found out about it. ‘The main unit was solid steel; we built a streamlined cover around the equipment,’ he says. ‘If you send a normal laminate down to 6,000m it will not be the same afterwards. We learned a few things from that project.’

In 1990, Baltic regained its independence. Finland’s industrial sector was in recession and Hollming needed to focus on its core business. ‘They asked us to arrange a management takeover,’ Johansson explains. ‘The yard was an important workplace for the local community and to shut it would have been very destructive. We were 32 employees who got together, took over and continued the business.’

Marketing manager Lisbeth Staffans stepped up to be managing director and led Baltic Yachts for two decades from a challenging start. ‘With a bad order book and uncertain future there were sleepless nights at the beginning of this new era,’ Johansson says. ‘Lisbeth was a very good person for that job. We couldn’t afford to make any mistakes and she made sure we didn’t. But this period is the one I’m most proud of. We did a good job, moved up in the size of our projects and stayed profitable.’

Innovation continued apace with production manager Christer Lill running a remarkably tight operation as the yachts ramped up rapidly in sophistication and size. In 1996 they launched 67ft Aledoa, the world’s first pre-preg carbon cruiser, and 87ft Anny – their first with a lifting keel, twin rudders and complex hydraulics. She had full push-button sail controls and a tender could be driven straight into the automatic opening-andlowering garage in her stern.

The following year, the Baltic 70 Vittfarne heralded a new style of yacht combining classic appearance and fine traditional craftsmanship with hitech construction, light displacement and modern hydrodynamics. ‘Bill Dixon’s team did a fantastic job on the design and our carpenters performed magic in building it,’ Johansson says.

Another Baltic 70, also launched in 1997, took carbon composite sandwich construction to a new level. The fully fitted interior of Loftfari was built almost entirely in pre-preg carbon/ Nomex honeycomb as well as her hull and deck, saving a large amount of additional weight.

It looked traditional, though, with thin veneers and fillets of teak covering all of the composite surfaces. Most Baltic yachts are now fitted out in a similar way.

The 78ft Super Baltic 5, delivered in 2000, was a major feat of engineering with a canting keel whose entire mechanism was installed in the shallow bilge beneath the saloon sole. She was calculated to be at least 3.5kts faster than an identical yacht with a fixed keel.

At the turn of the millennium Loftfari’s owner came back to Baltic with an impossible design brief, ‘or so it seemed at first,’ Johansson says. ‘To build a yacht in excess of 140ft capable of planing at 30 knots or more.’

The project was an immense challenge, not least because their largest build up to then was a 97- footer. Two years of development work followed before the owner gave the green light for the build to proceed. Remarkably the yacht was delivered six months ahead of schedule and exceeded all expectations.

Packed with unique innovations and with almost literally no expense spared, the Baltic 147 Visione was far ahead of her time and despite being 20 years old she is still quite capable of taking line honours in superyacht regattas today.

In build at the same time, the 141ft Canica challenged the yard in different ways. Performance was key but a lot of equipment and systems were also required to ensure a very high level of comfort on board. ‘That was the first yacht we built with a full floating interior,’ Baltic sales director Kenneth Nyfelt, son of founder Jan- Erik, explains.

‘We installed a highly complex Siemens PLC monitoring and control system, and it was the first project where we used noise and vibration consultants.’ With half the displacement of a typical 140ft cruising yacht, the performance targets were achieved and Canica can now be regarded as the first in a gradually evolving style of high-performance Baltic ‘super cruisers’ that continues to this day. A similar and parallel evolution of successful cruiser-racers began with Nilaya in 2010.

A stand-out project delivered in 2011, at 221ft LOA the Baltic 197 Hetairos is largest carbon composite sailing yacht in the world. A true wolf in sheep’s clothing with an incredible sail area : displacement ratio and a regular winner in superyacht regattas, the 60-metre ketch is classic on deck but thoroughly modern below the waterline with a unique lifting rudder as well as a lifting keel.

Around this time, the people who had staged the 1990 management takeover began to retire so new owners were needed. Two local investors bought shares in 2010; three years later an 80 per cent stake in Baltic Yachts was acquired by the German family-owned company Otto Bock – led by Professor Hans Georg Näder, a longstanding client of Baltic Yachts – and its future was secured. Henry Hawkins, a yacht captain with vast practical experience including many thousands of ocean miles as skipper of Näder’s yachts, joined Baltic, taking on a large part of Johansson’s role.

Näder’s own 175ft Pink Gin VI is one of the most notable recent builds and currently the world’s largest carbon composite sloop with a rig 16m taller than a J Class. Her key features include fold-down platforms in her topsides just above the waterline that are large enough to walk through, one amidships in the main saloon and one forward in the owner’s suite.

While relatively easy to build on a large motor yacht, putting large apertures in highly stressed parts of a sailing yacht hull without reducing its stiffness was a major engineering challenge, solved by mechanically locking the platforms firmly in place to become structural parts of the hull.

Another recent showcase of Baltic’s innovation is the 142ft Canova, which made headlines in 2019 as the world’s first superyacht with a DSS foil to reduce pitching and heeling, plus a host of other advanced features such as an immensely strong coachroof with a featherlight look and an electric drive system that provides enough regeneration capability under sail to cross the Atlantic without using any fossil fuel – with both sailing and hotel systems running.

After four years of cruising, a wide range of what used to be bleeding-edge technologies are now proven to work reliably.

To mark Baltic Yachts’ 50th anniversary, the first Baltic 46 Queen Anne returned to the yard last spring for a refit. Two of the men who built her – Johansson and Jan-Erik Nyfelt, whose grandchildren now work at Baltic – were delighted to find her in excellent condition, which a survey duly confirmed.

‘No structural works are needed, the hull appendages are sound, as is the mast,’ Hawkins says. ‘It’s also interesting that the original propulsion setup was still operational and in good order. The enjoyment at our end was the size of everything compared to today, from fibre technology to deck fittings. There are 18 winches on that boat; a modern 100-footer uses just seven or eight!’ She will be relaunched in June after a cosmetic refit, with a new engine.

What direction is Baltic Yachts likely to take in the future? The 68ft cruiser-racer Pink Gin Verde might hold a few clues with its 50 per cent flax fibre hull and micro-turbine hybrid propulsion system, but as Baltic’s CEO Anders Kurtén puts it, ‘That all depends on where our customers want to take us.’

‘We are fortunate and honoured to build some of the most exciting, groundbreaking custom sailing yachts in the world which means the next major milestone will forever be the next launch, summer 2023 being a perfect example,’ he says. ‘My best guess for the future is ever increasing sustainable practices and yachts with diminishing lifecycle emissions, as well as quantum leaps in terms of pure sailing performance.’

Click here for more information on Baltic Yachts

672 Wine Club

- Motorcycles

- Car of the Month

- Destinations

- Men’s Fashion

- Watch Collector

- Art & Collectibles

- Vacation Homes

- Celebrity Homes

- New Construction

- Home Design

- Electronics

- Fine Dining

- Benchmark Wines

- Brian Fox Art

- Disneyland Resort

- Ka La’I Wakiki Beach

- Kalamazoo Grill

- Raffles Hotels & Resorts

- Sports & Leisure

- Health & Wellness

- Best of the Best

- The Ultimate Gift Guide

This New Electric 110-Foot Sailing Yacht Gives You Two Ways to Cruise Emissions Free

Named after an ancient caribbean deity, "zemi" is one heavenly sloop., rachel cormack.

Digital Editor

Rachel Cormack's Most Recent Stories

- The Most Interesting Suite in the World Might Be on This Luxury Train

This New Catamaran Concept Was Designed to Carry Your Bugatti Across the High Seas

- Rolex Unveils the First Authorized History of the Submariner

- Share This Article

Baltic Yachts wants you to see its newest sailing yacht in all its glory.

Related Stories

The shipyard that built the ‘titanic’ has filed for bankruptcy.

- This Bonkers Space Balloon Just Completed Its First Full Test Flight

Zemi is also the third Baltic to be equipped with an electric propulsion system. Twin 129 kW Cummins generators provide grunt to a large bank of lithium-ion batteries that power an electric Danfoss motor. Baltic says the e-motor is quieter, cleaner, and smoother than traditional internal combustion mills. In fact, Zemi can cruise in “silent mode” sans emissions for long periods, according to the brand.

In addition, the yacht is equipped with twin rudders and a telescopic lifting keel with a 27-ton bulb that can reduce the draught from 20 feet to 13. It also has several headsail options that are suitable to different weather conditions.

Spearheaded by Andreas Martin-Löf, the interior features walnut and limestone veneers, sleek, modern furnishings, and cleverly integrated lighting. The main cockpit can be enjoyed in all conditions, with a fold-down spray hood and full-length removable bimini protecting guests from the elements. (Alternatively, the space can be left open for lounging in the sun.) Below deck lies a lounge, galley, and cabin for overnight journeys.

Another distinctive element of Zemi is McKeon trademark, wrap-over teak decking that runs from the bow right to the edge of the transom. The transom is expandable, too, meaning that the water is even easier to access from the swim platform. Also at the stern is a large garage that can hold a Williams tender.

Click here to see all the photos of Zemi.

Rachel Cormack is a digital editor at Robb Report. She cut her teeth writing for HuffPost, Concrete Playground, and several other online publications in Australia, before moving to New York at the…

Read More On:

- Baltic Yachts

- Sailing Yacht

More Marine

Meet Spitfire, a New 164-Foot Superyacht Based on a High-Performance Patrol Boat

What It’s Like to Watch an America’s Cup Race Right on the Water

Meet the Wine Club That Thinks Differently.

Receive editor-curated reds from boutique California producers four times a year.

Give the Gift of Luxury

Latest Galleries in Marine

Spitfire Superyacht in Photos

The AX/E 22 and AX/E 25 in Photos

More from our brands, halle berry shimmers in tamara ralph metallic dress at the ‘never let go’ red carpet premiere in new york city, fanduel parent buys italian gaming operator snai for $2.56 billion, anamaria vartolomei, diane kruger, lucas bravo begin shoot for french max original series ‘merteuil,’ a reimagining of ‘dangerous liaisons’ (exclusive), perrotin gallery donates 23 works to the pompidou centre by artists including takashi murakami, emma webster, and genesis belanger, the best yoga mats for any practice, according to instructors.

Yachting World

- Digital Edition

Baltic 67 review: Finnish superyacht yard goes back to its roots with no-compromise cruiser

- Toby Hodges

- March 28, 2019

When a renowned superyacht yard builds a 67-footer for short-handed cruising you can be sure the result will be something special

Were money no object and you wanted the ultimate yacht for long-term cruising, what would you choose? How large could you go without needing a paid crew? What do you really need length and space for and how important is displacement and potential speed to you?

These were the sort of questions crowding into my head on first viewing the sensational new Baltic 67 at the Cannes Yachting Festival . It is truly striking. The quality of the yacht is undeniably world class, but it’s the precision of design and engineering that soon absorbs you.

The owner of this first boat is a highly experienced cruising sailor, boat owner and navigator, so joining him for a 24-hour trial from Mallorca proved the ideal way to get under the gleaming composite skin of this athletic new model.

The concept is about combining the pleasure of pure sailing with ease of handling for long-distance cruising at high average speeds. It is the alternative to a full custom yacht – all the engineering is already calculated – but a great deal of flexibility has been worked into the design, with options including single or twin rudders, a fixed or telescopic keel, multiple cabin layouts, and a carbon or epoxy sandwich hull.

Wanting to return to its mid-size fast cruiser roots, Baltic Yachts teamed up with designers and fellow in-demand superyacht specialists Judel Vrolijk and Design Unlimited. The result is this exceedingly attractive, modern-looking sloop, with a powerful hull shape, a flush foredeck and a low-profile coachroof.

Powered sail handling systems means Manyeleti can be sailed by just two

The Baltic 67 is very much at the luxury and custom end of the production yacht scale, so our light wind trial of the boat focused more on the various choices and details aboard and how they might be relevant to sailors in general. Hull number one in particular had a lot of owner input.

Manyeleti , the first 67, belongs to Erik Lindgren. It is his fifth yacht from Baltic after a string of upgrades that started with a used 39 in 1989. “It’s very different to design and build your own boat – in my case using nearly 30 years of offshore sailing experience,” Lindgren explains.

Swede Lindgren travelled to the yard once a month and was in daily contact with the project manager, Kjell Vesto.

The Lindgrens’ plan is to head off on another world cruise in a couple of years time, when Erik’s teenage children have finished school. His shakedown sail involved a 5,000-mile trip from Finland to and around the Mediterranean.

“Not a single thing broke,” he reports, saluting Baltic’s build quality. “I could literally go to El Corte Inglés, stock up, fuel up and sail across the Atlantic.”

CNB 76 boat test – more boat for your money

It may sound daunting, but it seems 60ft is no longer a big boat. In typical Philippe Briand fashion the…

Walk the course with Mike Broughton- navigator onboard the brand new Baltic 115 Nikata

Start date: Monday 22nd February 2016 Course: Approx. 600nm non-stop around 11 Caribbean Islands Organised by: The Royal Ocean Racing…

The Baltic 67 is as big as you can go without needing a pro crew, argues Erik Lindgren. “I’ve spent a lot of time on World ARC boats… it’s the details that make living on board easier. This is a technical boat, but is less dependent on systems than our old Baltic 56. On the other hand it’s great to have aircon and a lifting keel.

“Half the time spent aboard will be for long distance stuff and holidays for the two of us, but a lot of the time will be spent with friends and family too.”

Privacy at this size is a big benefit. “I have no need to have a big boat for show,” says Lindgren, “but I wanted to have the things I need.”

The retractable arm for the anchor roller is an engineering masterpiece. It rises from the anchor locker at the touch of a button

The most important features he wanted, which help explain the jump in size from his previous 56, were a furling boom, a large, practical galley, four cabins and a tender garage large enough to house a forward-facing dinghy. While his yachts have grown and become more complex, Lindgren maintains that the methodical way Baltic builds boats results in a lot fewer problems.

A carbon furling boom is an eye-watering investment, but it does make the hoisting, reefing and lowering of sails a quick and largely hassle-free procedure. It can make the difference to whether you go sailing or not. Within minutes of leaving Palma’s breakwaters, we had main and jib unfurled and were matching the 8 knot wind speeds.

Manyeleti is hull number one in the Baltic 67 series

Easy performance

The Hall carbon boom uses an electric mandrel motor that is synchronised with the halyard to avoid too much sail spilling out during a hoist. The traveller is also electric, while the sheet car pullers, backstay, vang and furlers are hydraulically-operated. The result is the ease of push-button sailing typically used on modern performance superyachts.

We spent the first few hours reaching across Palma Bay. Despite having 24 hours aboard, the most breeze we found was 11 knots, which translated to 9.5 knots boatspeed – very respectable under white sails only (fully battened main and non-overlapping jib). The majority of the time was spent close-hauled, matching the single-figure wind, even exceeding it when it dropped below 6 knots.

Neat details: the forward end of the jib car puller, which is hydraulically powered

I found myself gravitating to the side deck to sit and steer, instinctively wanting to sail the Baltic 67 like a cruiser-racer. There are good views over the low coachroof and flush foredeck, but nothing except freeboard height to prevent a wet backside if the decks ship green water.

The helmsman can also sit forward of the wheel and reach the two winches. I like the way the primary is mounted inboard, though the positioning of the turning block for the jib sheet creates an obstacle on the side deck. Baltic reasons that it helps provide the option to use either winch for the sheet.

Speed for oceans

A flying sail would have helped to get the most out of the conditions, but Lindgren was still awaiting delivery of a Code 0 and A3, both on top-down furlers. However, even when the evening breeze died to around 4-5 knots, the Baltic 67 still provided an enjoyable experience on the helm. It’s rare that you can say such a thing while only using main and jib.

The 67 is designed for potent offwind performance, to limit engine use on transocean voyages. The aggressive sail area to displacement ratio of 30.9 is possibly taking things too far: the boat has so much power to weight that it will need to be treated as a real performance cruiser and tamed accordingly (i.e. reefed early). But what our trial sail did show was how well the Baltic 67 fulfils its brief of being able to offer enjoyable sailing in light wind.

“Bluewater boats don’t usually sail in 10-15 knots downwind – and we had a lot of that,” Lindgren points out, with reference to their previous Pacific crossing. “At 150º true, this boat is sailing at 8-9 knots, which is a big difference. As long as you are over 8 knots you are properly moving through the water,” he reasons. “Below that you’re in the swell and not in control.”

The twin pedestals are well designed to site plotter screens and remote controls for powered deck functions and sail handling

With the relatively low coachroof and cockpit backrests and aft positioning of the helms, protection from the elements may be a concern. When you look at Baltic’s large new designs in build, the 142 and 146, both have lengthy deckhouses that provide plenty of protection. But it chose the more in-vogue deck design for this semi-custom size, so its solutions for cockpit protection depend largely on a retractable sprayhood and bimini. These can remain in place while sailing and have already been tested in up to 40 knots.

The cockpit area on this first Baltic 67 has been adapted according to the owners’ wishes, including a narrower space between benches and no fixed table. The Lindgrens like to be able to brace feet between benches and to be able to sleep on the sole between them when offshore. The table and carbon legs stow beneath the central saloon soleboards.

We anchored at dusk at Es Trenc beach, 25 miles to the south-east of Palma, in water so clear we could pick the spot to drop the hook between weed patches. The ability to anchor in less than 4m amply demonstrated the appeal of a lifting keel. The keel system, from the highly reputable Italian brand APM, raises the T-keel hydraulically up to 2.5m.

The anchor arrangement is another fine piece of engineering: the arm is concealed in a shallow locker and rotates over and into place at the push of a button. The roller then extends out to keep it clear of the stem. The second Baltic 67 will have a fixed roller incorporated into the bowsprit.

The furling jib and powered padeye are recessed neatly

Open transom choice

The garage houses a 3.2m dinghy stowed longitudinally, with the engine mounted, between the dual rudders. Lindgren chose an AB tender with aluminium hull (53kg). It has a 20hp outboard so can plane with four adults yet is light enough to be dragged up the beach. He also opted for an open transom that, although an unconventional choice for ocean cruising, gives easy access to the swim platform and dinghy.

There is copious stowage space throughout the Baltic 67. In addition to the tall sail locker in the forepeak, the aft quarter lockers easily swallow electric bikes, inflatable paddleboards, snorkel gear, waterskis, spare fuel and a liferaft valise. Here there’s also access to the steering gear with independent autopilots used on both quadrants.

I particularly like the way multiple Antal T-lock fittings are flush-mounted along the toerail and in the cockpit. These enable quick and easy swivelling toggles to be inserted for loops and blocks, or for harness attachments.

Weight versus noise

The following morning was windless, leaving us with a three-hour motor back to Palma. The 150hp six-cylinder Steyr was specified for its low noise and emissions, and drives a four-blade Bruntons prop via a standard shaft.

E-glass was chosen over the standard carbon hull. Lindgren’s previous Baltic 56 was carbon and he wanted the better noise insulation over the weight difference (up to one tonne). The 67 is a very quiet, relaxing boat under motor, with no need to raise voices under power.

The spacious saloon has enough room for both dining and coffee tables

Down below the Baltic is an aircon-cooled haven of charm and exquisite quality. The more time I spent aboard and the more I learned of the systems and engineering, the more I began to appreciate what sets this boat apart.

The Design Unlimited styling is elegant and tasteful, with a mahogany finish on this first boat. With four different layout configurations plenty of scope is allowed for owner customisation. But behind the scenes is what you really pay for with the Baltic. It’s the telling result of what happens when a yard goes down in model size – this 67 is built like a superyacht.

For example, the engine room, used for hot items like engine, genset and water-heater, links through to a proper mechanical/utility room abaft the galley, where equipment is mounted on three walls for easy access (including chargers, inverters, pumps, watermaker and compressors).

“The thinking is that everything should be in reach and that you should be able to maintain it easily,” says Lindgren, pointing to the Spectra watermaker (his fourth) mounted on one bulkhead.

The boat’s systems are beautifully laid out for ease of inspection and maintenance

Stowage throughout has been brilliantly conceived. The 2,000lt of water and diesel tanks, plus the batteries, are all mounted centrally, under the saloon, leaving cavernous practical stowage under the berths. Custom-made fabric bags are used under the saloon seats to maximise useable volume.

Lifting the carbon sandwich soleboards at the base of the companionway reveals the sea chests and main manifolds for fuel and water, a prime example of the meticulous and practical systems layout. The 1,440Ah of lithium gel batteries further forward have a reservoir surrounding them, which can cool the cells if necessary without flooding them. And there are custom-made drip trays below any filters to prevent mess or corrosion.

The keel uses a Programmable Logic Controller (PLC) to activate the hydraulics, the cylinders for which can be replaced from within the boat. All other electrics are on manual relays. The fuse locker is a work of art and opens out for full access to the wiring, with every wire and fuse numbered and labelled.

Smart cabin choice

Manyeleti ’s owner’s cabin, with adjoining heads and shower in the forwardmost section, has an offset double berth positioned aft by the main bulkhead, a relatively central area of the boat to sleep. However, on passage, Lindgren says he sleeps on deck, or in the single cabin amidships. There are also leecloths on the saloon berths, a comfortable option if guests don’t want to share the twins.

The owner’s cabin is (purposefully) the only one aboard Manyeleti to feature a double bed

There is a good reason why there is only one double bed. Lindgren often sails with male friends, hence twin and single berths are a pragmatic choice. The use of a split heads and shower shared between the twin and single cabins is also sensible.

The central section of the interior is superb, with a traditional lower saloon, a navstation beside the companionway and a formidable U-shaped galley. It was important to the Lindgrens that the galley was large enough for two to work in yet still be seamanlike. The result is a very practical area with superb chilled, dried goods and crockery stowage. Ventilation ducts keep it nice and cool, though personally I’d want to have a hatch through to the cockpit.

Lindgren swears by the dishwasher, reasoning that it uses less water than washing up and helps keep the galley tidy. This and an induction cooker would be sensible options if you had sufficient power, and would avoid the need for gas.

The exemplary finish and smaller details help furnish the boat with a top quality feel. From the hinges, light switches and showerheads to the gas sprung hatches and overall joiner work, the Baltic 67 oozes quality.

The Baltic 67 has been designed with short-handed sailing in mind

Baltic 67: the verdict

Baltic has spent the last decade building some of the finest performance superyachts. You don’t receive commissions for yachts such as Hetairos , Pink Gin VI , or My Song without a top reputation, and to get that sort of quality on a 67-footer is truly special. Attention to detail and class of engineering and finish are hallmarks of this new model.

The Baltic 67 has the performance in light airs to match her on-trend looks and is a joy to helm. The choice of a comparatively unprotected cockpit and an open transom may not sit well with conventional bluewater sailors, but times are changing and this design is aimed as much at port-hopping from Portofino as at Pacific passagemaking . It is the solutions, stowage and systems employed throughout that help make it a valid option for distance cruising.

The Baltic 67 has the legs to outrun virtually any other cruising monohull and to keep sailing fast in light apparent winds. To know you’re buying the best in terms of design and composite build – and created by the same team involved in a yacht that costs tens of millions – must help compensate for the significant initial outlay. For the rest of us, we can but dream.

Specification

LOA: 20.52m (67ft 4in)

LWL: 19.20m (62ft 12in)

Beam (max): 5.45m (17ft 11in)

Draught (max): 3.90m (12ft 10in)

Draught (telescopic): 2.50m (8ft 2in)

Displacement (lightship): 24,400kg (53,792lb)

Ballast: 9,000kg (19,841lb)

Sail Area: 255.6m2 (2,751ft2)

Berths: 7-8

Engine: 150hp

Water: 1,000lt (220gal)

Fuel: 900lt (198gal)

Sail Area/disp ratio: 30.9

Disp/LWL ratio: 96

Price: €3.95 million (ex. VAT)

Design: Judel/Vrolijk & Co and Design Unlimited

The global authority in superyachting

- NEWSLETTERS

- Yachts Home

- The Superyacht Directory

- Yacht Reports

- Brokerage News

- The largest yachts in the world

- The Register

- Yacht Advice

- Yacht Design

- 12m to 24m yachts

- Monaco Yacht Show

- Builder Directory

- Designer Directory

- Interior Design Directory

- Naval Architect Directory

- Yachts for sale home

- Motor yachts

- Sailing yachts

- Explorer yachts

- Classic yachts

- Sale Broker Directory

- Charter Home

- Yachts for Charter

- Charter Destinations

- Charter Broker Directory

- Destinations Home

- Mediterranean

- South Pacific

- Rest of the World

- Boat Life Home

- Owners' Experiences

- Conservation and Philanthropy

- Interiors Suppliers

- Owners' Club

- Captains' Club

- BOAT Showcase

- Boat Presents

- Events Home

- World Superyacht Awards

- Superyacht Design Festival

- Design and Innovation Awards

- Young Designer of the Year Award

- Artistry and Craft Awards

- Explorer Yachts Summit

- Ocean Talks

- The Ocean Awards

- BOAT Connect

- Between the bays

- Golf Invitational

- BOATPro Home

- Superyacht Insight

- Global Order Book

- Premium Content

- Product Features

- Testimonials

- Pricing Plan

- Tenders & Equipment

Inside the Baltic 142 Foiling Superyacht Canova

Finnish yard Baltic Yachts has released first-look images inside its recently delivered 43.3 metre Baltic 142 Custom sailing yacht Canova.

The yacht was delivered following the completion of successful sea trials off the coast of Finland on October 20.

The yard said the Lucio Micheletti-designed interior had recently received its "finishing touches" and described it as "a study in understated interior design with white bulkhead panelling and deckheads combining with teak timber veneers."

It comes after the yard put the innovative DSS foiling technology through its paces during sea trials. Baltic released a video showing the nine metre "long sliding foil" in action and reported a good performance under sail.

"As the speed increases, the heel angle of the yacht reduces, no other system can do this. When the foil is deployed it extends 22ft (6.5m) to leeward," it said.

The yard also reported testing the foil upwind in winds of 20-25 knots, which "proved itself faster and with much less heel".

Canova , a sloop-rigged performance cruising yacht, features naval architecture and exterior styling by Farr Yacht Design while Lucio Micheletti collaborated with the in-house team at Baltic Yachts on the interior styling.

Canova stands out for being the first yacht of her size to be fitted with the DSS foil, which is designed to improve comfort and performance capabilities.

Canova features this innovative use of sailing technology, specifically its dynamic stability system. Developed in collaboration with Gordon Kay from Infiniti Performance Yachts, the system employs a sliding foil that can extend up to nine metres. This feature has featured on smaller yachts, but this is the first time it will be employed on a large sailing superyacht .

The foil has been designed to be deployed when the yacht is sailing at speed. The estimated result is a top speed increase of 5 to 20 per cent, depending on the conditions. The foil runs directly beneath the owner's cabin amidships.

During Canova’s first sailing sea trials, the push-button deployment of the nine metre long foil was reported as being "faultless" and she showed a reduction in heel and pitching motion in stronger wind conditions.

Gordon Kay of Infiniti Yachts previously said, “Having installed DSS in dozens of yachts we can confidently say we have reached another level with the impeccable installation of the foil case in the Baltic 142 Canova”.

Vice president at Farr Yacht Design Britton Ward added: "The predicted performance numbers are remarkable with the boat able to comfortably achieve boat speeds equal to wind speed in moderate to strong conditions".

To make the most of her performance, Canova has an extremely powerful rig and sail plan. A squaretop mainsail with a 3.5m long horizontal batten pushes the mainsail area up to 570 square metres, and her Her J1 adds another 390 square metres. All sails are by North Sails, while her all-carbon rig is by Rondal. The latter utilises Carbo-Link standing rigging, which is specifically designed to handle the increased loads generated by the additional stability delivered by the DSS foil.

Accommodation is for up to eight guests split across four cabins including an amidships owner’s suite. A long Bimini hardtop will extend out from the coachroof over the cockpit, providing a shaded al fresco relaxation spot and powered windows that lower at the touch of a button will provide further shelter in this area.

Other key features include a diesel electric Visedo/Cummins propulsion system, nine metre beam and a lifting keel that can reduce the draught from 6.5 metres to 3.8 metres.

Also put to the test during the sea trials on Canova was her innovative diesel electric propulsion and hydro-generating system. Both have been proven to substantially reduce noise and vibration while she is under power. The yard has reported that "during motoring trials the electric propulsion system was barely audible aboard the yacht."

Canova can use her propeller as a hydro-generator via the electric motor, which then charges her six banks of Lithium ion batteries.

The compact and quiet 420kW electric motor is able to drive the 145-ton yacht at a speed of 14 knots via her rotating, forward-facing, pull propeller, says Mattia Belleri of fluidsailing, who has project managed the design and build of Canova for her owner.

“The preliminary numbers are promising and we are confident fine tuning will deliver the performance we are expecting," says Kim Kolam, Senior Electrical Engineer at Baltic Yachts.

Sign up to BOAT Briefing email

Latest news, brokerage headlines and yacht exclusives, every weekday

By signing up for BOAT newsletters, you agree to our Terms of Use and our Privacy Policy .

More about this yacht

Similar yachts for sale, more stories, most popular, from our partners, sponsored listings.

- Nautic Shows

- America’s Cup

- Classic Yachts

- Motor Yachts

- Sailing Yachts

- Superyachts

- Yachts News

- Destinations

- Yacht Clubs

- Yacht Club Monaco

- Boat Racing

- Meta Yachts

Baltic Yachts has been commissioned to build an ultra lightweight, 111ft superyacht described as ‘one of the most extreme projects Baltic has undertaken’.

Designed for fast coastal and offshore sailing, Baltic 111 Custom will begin construction in April taking full advantage of Baltic Yachts’ ability to build an advanced composite structure to the most exacting standards, creating a modern, stylish living platform within a high-performance design envelope. The new yacht, described as a ‘ground-breaking design with spectacular technical solutions’ is an extremely weight sensitive project, a key reason why Baltic Yachts was selected. The company’s proven track record and expertise in calculating weight, monitoring it during build and achieving design targets, were decisive in the choice of builder, as were Baltic Yachts’ problem-solving abilities through innovation and attention to detail. Baltic Yachts CEO Anders Kurtén, said: