The $tingy Sailor

Diy trailerable sailboat restoration and improvement without throwing your budget overboard.

How to Step a Mast Single-Handed With or Without Using the Boom as a Gin Pole

How do you step the mast on your trailerable sailboat? With a gin pole? With the trailer winch? With the help of friends or family? With your fingers crossed? No single system works for every sailboat or for every skipper. If you’re new to mast stepping, you don’t like your current method, or you just want to simplify or speed up the process, this post is for you. I must warn you though, this is a long post, even for me. To make it as short as possible, I’ve included five YouTube videos that show how this system works. By the end of this post, you’ll know everything about how I step the mast on Summer Dance single-handed in minutes, even on the water.

I’ll describe two ways that I step the mast, including one way that doesn’t use a gin pole at all. Both are fast and mostly use the boat’s own rigging and very little extra gear.

I’ll also explain some topics that lead up to and follow mast stepping, like how I:

- Use a DIY telescoping mast crutch for easier stepping and secure trailering.

- Tie down the mast and rigging for trailering.

- Keep my mast in tune without having to loosen and re-tighten the shroud turnbuckles to step the mast.

What do you really need?

When I started trailering Summer Dance years ago, I researched a lot about mast stepping. The Catalina 22 Owner’s Manual and General Handbook is pretty brief on the subject.

Walk the mast aft and drop the mast foot into the mast step on top of the deck, keeping the mast in center line of boat, insert the pivot bolt and locking nut. One crew member should pull on a line tied securely to the forestay while another pushes up on the mast and walks from the cockpit forward. With the mast erect, attach the forestay and forward lower shrouds.

Poorly written but pretty simple, huh? One crew member pulls on the forestay while another pushes on the mast. That’s how the mast was designed to be stepped and it works well if you’re young, strong, and there are two or more of you to do the job.

But what if you don’t normally have a second able crew member? What if you need to step the mast on the water? What if you want to lower the mast to go under a bridge? What if you or your crew have a physical impairment that prevents them from performing one of the tasks? That system may not work for you and you need an alternative. If you believe in the rule that you should have a backup for every critical part and system, then you also need a backup mast stepping plan even if you normally step the mast with the factory recommended method.

I’ve read about lots of different systems. Maybe you have too:

- Factory-built gin poles, braces, guy wires, and mast-ups

- DIY wooden gin poles with winches, bridles, and brace poles

- Blocks attached to the pulpit to reuse the trailer winch cable

- Electric winches on the trailer or in the tow vehicle

- Jumbo bungee cord connected to the forestay

- Assorted Rube Goldberg variations on all the above

They all struck me as overkill for the real problem. What do you really need once you have the mast bolted to the step? What do all of these system have in common? Some mechanical advantage to raise the mast and a way to keep it from swinging too far sideways until the shrouds tighten.

If you’ve read this blog for very long at all, you know that I’m really big on reusing or repurposing things for other uses. It’s something of a prerequisite to be a stingy sailor. If you’re lucky, it’s in your DNA and it comes easily to you. Being an armchair engineer qualifies too.

Let’s see — sailboat design is all about capturing, multiplying, and redirecting forces for mechanical advantage: the hull, keel, rudder, mast, sails, rigging, almost everything. What’s the most compact, portable piece of gear on a sailboat that creates mechanical advantage? The main sheet or the boom vang typically multiplies the force applied to it by three or four times. What are all gin poles in their most basic form? A big stick. Is there already a long, stiff, portable, stick onboard? The boom. Can we raise and lower the mast single-handed with the main sheet and the boom?

As it turns out, it’s really pretty easy to do. But it’s not very easy to describe in words, so rather than write an entire book about it, I’ve made a series of short videos that each show a different aspect of my mast stepping system. I’ll give you an overview of each aspect in the text below but to really get it, you should watch the videos.

Getting it to the water

Besides being simpler, one of the basic principles of this system is to make launching and retrieving the boat as quick as possible while also being safe. That starts with securing the mast and rigging for trailering. For me, it has to be secure enough to tow for a hundred miles over bumpy state highways and county backroads to my favorite cruising spots. This is in north Idaho, mind you, which is relatively remote compared to the Florida coast or southern California.

I use a combination of DIY mast supports, motorcycle straps, and inexpensive ball cords to secure the rig. The mast is supported on both ends and in the middle. This follows closely the Catalina 22 Owner’s Manual and General Handbook recommendation.

Tie the mast and boom securely to the bow and stern pulpits. The spars should also be supported in the middle by the cabin top. Pad the mast at all contact points to prevent damage.

No tools or knot tying are needed for my system and any one of them works in seconds and stows easily either onboard or in my pickup.

Here’s a tour of the rig tied down just before I step the mast.

The previous video mentions my DIY mast stepper, also called a Mastup by a popular online Catalina parts retailer. I haven’t yet devoted a blog post to it but it was pretty easy to make. If you’re interested in a fabrication drawing and materials list, keep reading to the end of this post and a special offer.

I bought the steel myself from the cutoff pile at a local metal distributor. I took the metal and my drawing to a local welder who advertised on craigslist.com. I painted and assembled it myself. The total cost was half the price of the commercial version and in some ways, works even better. I especially like the D rings, which make it simple to secure the top of the mast stepper to the aft mooring cleats while trailering. It holds the mast very solid that way. And because the pintles are welded in place instead of adjustable, they can’t accidentally loosen and drop the mast.

Following is a close-up video of just the mast stepper. You can see it in action in the last two videos.

Setting up the boom as a gin pole

The basic theory of a gin pole is to lift a heavy object below one end while it remains stationary at the other end. Support lines called guys position the lifting end over the object that is raised. A mast raising gin pole has one end stationary near the base of the mast, uses the forestay to support the lifting end, and uses a winch or a block and tackle to theoretically raise the bow of the sailboat to the end of the gin pole. In reality, the bow stays stationary and the entire gin pole system including its base (the mast) are raised towards the bow.

Most C-22 gin poles use one of two methods to attach the gin pole to the mast:

- A peg on one end of the pole that fits in a hole in the mast (the factory system for 2nd generation C-22s)

- A saddle on the end of the gin pole that fits around and is strapped to the mast (most DIY systems)

Neither of those gin poles serve any purpose after the mast is raised. They’re useless extra weight that takes extra storage space.

The system I use attaches using a small right angle bracket. I fabricated it out of a piece of scrap aluminum I already had. One side of the bracket is bolted through the mast step and the cabin top in front of the mast. The other side the bracket points upward and has a 1/4″ hole through it to act as a hinge for the gooseneck (stationary lower) end of the boom. If you’re a follower of this blog and have the password, you can find a scale drawing of this bracket on the Downloads page.

I connect the gooseneck fitting to the bracket with the same quick pin (drop cam or toggling bimini type) that I use to connect the gooseneck fitting to the mast slide while sailing. The pin is tethered to the boom with a stainless steel lanyard so it can’t get lost and it’s always near at hand.

I connect the forestay to a shackle on the top side of the (upper) end of the boom. On the opposite (bottom) side of the boom from the forestay, I connect the end of my main sheet tackle that doesn’t have the cam cleat. This is the same configuration as when the main sheet is attached for sailing. I connect the other end of the main sheet (that’s normally attached to the traveler car) to the stem plate where the forestay is normally attached.

To hold the boom vertical during raising, I sometimes use two pieces of pre-tied accessory cord. They connect to the sides of the boom with clips through the eye straps where my boom topping lift and jiffy reefing lines attach. The other ends of the cords have loops tied into them that I tie to the upper ends of the midship lifeline stanchions with girth (cow) hitches. The mast step is nearly in-line with the tops of the stanchions, so the cords rotate around the same pivot point as the mast and the boom.

If your sailboat doesn’t have the same style of gooseneck fitting as a Catalina 22 or you can’t use your boom for some other reason but you do have a spinnaker pole, you might be able to use it instead as this picture from a Westerly 21 owner shows. This picture also shows that a gin pole can be a great help with lifting the extra weight added by a furler.

That’s kind of hard to visualize, so here’s a short video that takes you on a tour of the setup.

This is a stickup with a boom!

After I rig the boom like shown above, the hard part is over. The rest is just pulling the main sheet with one hand while I steady the mast with my other hand. I also watch the stays and shrouds to be sure they don’t catch on anything as they raise off the deck.

With the main sheet cam cleat at the stem plate, I can easily stop raising the mast at any point, cleat the line with a sharp tug, and then clear snags or move to a better lifting position. Then I uncleat the main sheet at the stem plate first and hold light tension on the main sheet while I get into position to resume raising the mast.

The mast only needs to be held centered until it reaches about a 45° angle. Then the upper shrouds begin to tighten and they hold it centered the rest of the way up.

When the mast is vertical, I reconnect the forestay and forward lower shrouds using quick release levers . The mast is back in tune and requires no further adjustment. I disconnect the boom from the system and attach it in its normal place between the mast slide and the topping lift or backstay pendant. I disconnect the main sheet and attach it to the traveler car. All I need to put away are the two accessory cords if I used them, which I typically only do when it’s windy, when I’m setting up in a unlevel area, or on the water when its choppy.

Here’s a video showing the entire process completed in about 4 and a half leisurely minutes.

Single-handed speed stepping

In good conditions (light breeze, level area, or calm water), I skip over using the boom as a gin pole entirely and just use the main sheet to pull the mast up by the forestay. It saves several minutes and is nearly as easy to do but you should be fitter than average to attempt it. It’s the single-handed equivalent of having a crew member in front of the boat pull a line attached to the forestay. Bystanders seem to enjoy watching me raise the mast by myself in seconds.

Here’s what it looks like when it’s done on the water.

Back to the beginning

At the end of a road trip, I never look forward to tearing down Summer Dance , pulling her out of the water, and tying her down for the ride home. I’ve had a great time but I’m tired and there’s many miles to go before I sleep. I don’t want to spend an hour lowering the mast and tying the rig down. I want it to be quick and simple.

Almost always, I lower the mast without using the boom as a gin pole even if I raised it that way. A gin pole is just not usually necessary so long as the mast comes down slow enough and lands in the crutch. You might not want to do it that way your first few times, so here’s what it looks like using the boom as a gin pole.

Then I tie it all down in a few minutes like shown in the first video.

Special offer for blog followers

Whew! That’s a lot of info. If you stuck with me through it, I really appreciate it. I want to thank you by offering not one, but two free bonuses to my blog followers.

The first is the launch checklist that I use to prepare and launch Summer Dance . It’s two pages of items that can help make sure you don’t forget something important for your next cruise — everything from an umbrella for the first mate while she waits for you to step the mast, to step-by-step instructions that you can have on deck for the gin pole method described above. Use it as a starting point to add and remove items to make your own checklist.

The second bonus is a dimensioned drawing and materials list for my DIY mast crutch that is described at the beginning of this post. Use it to build your own and save some money for something else.

If you’re already a subscriber to this blog, you can download both of the free bonuses from my Downloads page using the password that you received when you subscribed. If you’re not already a subscribed to this blog, sign up and you’ll join the thousands of other stingy sailors. Just enter your email address in the box at the bottom of this page and then click the Subscribe button. You can unsubscribe at any time and I won’t share your address with anyone, ever.

I hope you’ve picked up some tips from this post that you can use to optimize your mast stepping system and spend more time on the water.

Would you like to be notified when I publish more posts like this? Enter your email address below to follow this blog and receive notifications of new posts by email. You will also receive occasional newsletters with exclusive info and deals only for followers and the password to the Downloads page. It’s free and you can unsubscribe at any time but almost nobody does!

Subscribe to Blog via Email

Enter your email address to subscribe to this blog and receive notifications of new posts by email.

Email Address:

Share this:

58 thoughts on “ how to step a mast single-handed with or without using the boom as a gin pole ”.

Love your vids on raising mast. Could you send a pic of quick release on forward shrouds and forstay and the pin you spoke of in vid.

Stay tuned here for a separate post on the quick releases and maintaining mast tune that’s coming soon!

I like the idea of using PVC tube & fence to make mast supports.

Just some scraps I had on hand; lightweight, strong, and they don’t look too ghetto.

Hey $tingy,

Thanks for another great post.

You mention the newsletter. I am definitely a long time blog follower, and look forward to every post, but I have never gotten a newsletter. Could you add me to whatever email list you use? I don’t want to miss any more.

Hi, CapnRehab

You weren’t receiving the newsletter initially because you’re a WordPress user so if you follow, my posts should show up in your Reader list instead of by email. But I added your email address to the newsletter recipient list back on May 11. The last newsletter went out on May 21 titled What’s Your Favorite DIY Project? Did you get that one? I’ll probably shoot out the next one at the end of the month. If you don’t get it, I don’t know what more I can do on my end.

Brilliant repurpose of mainsheet. I’ve struggled with this procedure for years, just man-handling it up there. Can’t wait to try this!

I hope it works for you. Let me know how it goes!

For mast raising and lowering, I have it a little easier with a 16ft boat, and can raise the mast single handed juat by manually lifting and walking forward in the cockpit and onto the keel case with the hatch slid forward, although I usually have my wife tension the forestay for some extra assurance.

I like your use of the “ball ties” for securing the rigging on the trailer. I usually use the halyards to tie everything up, but that takes more time than it should. I use some “sail ties” which are very similar to your ball ties to secure the sail on the boom and the boom is stowed inside the cabin. I think I will either get some more sail ties for securing the rigging on the trailer, or make up some velcro webbing straps. At the bow, my mast is tied down using my bowline and the DIY timber A frame mast crutch tied down at the rear with a rope tied to cleats on either side of the transom. The boat is held to the trailer using a stern ratchet strap and a turnbuckle on the bow, and the winch cable attached.

I really like the idea of using the boom as a gin pole. Brilliant. I wonder if you could post a picture of the L-shaped aluminum bracket that you fabricated and how it is attached to the boom? Making that may be the tricky part for me to get this thing. I could not really see a clear picture of it in your videos. Thanks!

I’ll add a close-up shot of it soon.

I added a close-up picture of the hinge bracket about midway through the post.

Excellent blog and report. I struggle with the mast raising and have an assistant. I will give your system a try. I finally understand the function of a gin pole and how to use it.

That’s awesome, Richie. I’m really glad it helped. In the case of a sailboat, it’s just a long, temporary lever. Aha moments are great!

Excellent report and diagram on the mast stepper. What would you think about using aluminum to build it instead of steel?

I think aluminum would work great so long as the wall thickness of the tubes is adequate. You wouldn’t need to be concerned about painting or rust. The critical area is where the outer tube overlaps the inner tube when the crutch is extended. Depending on how close the fit is and how much overlap, when you’re rolling the mast back to set it in the step, there can be considerable strain on that “joint.” A thin wall or soft aluminum might deform so make it beefy there.

Thanks for your comment, Michael!

I spoke to my fabricator friend about using aluminum and, him not knowing about the stepping process was most concerned about the hinges holding weight while trailering over the road. He also suggested using a beefier thickness if choosing aluminum just like your suggestion.

thanks for all you do!!!

The gudgeons can easily handle the weight so long as the pintles on the crutch are sturdy.

Send us a good picture of the final product and I’ll add it at the end of the post as an example!

Great post. Just started following your site. You have a lot of good projects on here. Where did you find such thin-walled square tubing for your mast stepper? All I can find is telescoping 1-3/4 & 1″ tubing. I don’t think I need that much strength or weight. Also, I receive the posts by e-mail but I never received the password for the download section. Thanks

There are a couple of industrial metal suppliers in my area that sell their cut-offs retail to the public by the pound. One of them also sells small quantities of standard sizes. I found all the sizes I needed with very little cutting. You definitely don’t need much strength and as little weight as possible. Aluminum would be even better if you can get it welded.

I’ll send you the password by email.

Thanks for your question.

I really like the simplicity of raising the mast without a gin pole. I use a gin pole now but prefer a simpler approach. How to you lower your mast? Do you use your mainsheet tackle when lowering? Thanks for the great video.. Jim Mathews

That’s right, Jim. I lower the mast by the same method but in reverse, which helps to remember the steps in both directions.

Thanks for your question!

Hi. I’m making the mast crutch and downloaded the drawing. How far down is the second hole in the 1″ tubing? ie. the hole where I would put the lock pin when the crutch is raised. Thanks.

That’s an excellent question, Jim, since it wasn’t shown on the drawing. I’ve since revised the drawing to show the hole 2″ up from the bottom of the inner tube.

The distance isn’t critical but depending on how tight the fit is between the inner and the outer tube, the hole might work better even farther up the inner tube. Try it at 2″ and if the top tube is too loose for you and it wobbles around, drill another hole farther up the inner tube, say at 4″ and try that. The mast will sit 2″ lower but it shouldn’t affect how you step the mast other than by making the crutch sturdier. Then you will have two holes to choose from. You can even drill more holes at different heights for different purposes.

Hi Thanks for the blog. Some pretty interesting ideas here, I’m borrowing some, especially related to the sails… Seeing your “system” to step the mast, I’m trying to adapt it to my boat, a ’82 French Rocca Super Chausey. The mast step has no pin to lock to the mast foot, it just falls into place between two pins that limit its longitudinal travel. Hence, nothing for the mast to pivot on. Any thoughts on how I could achieve that effect? Thanks.

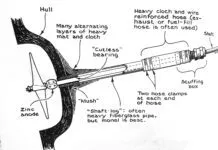

If you have the tools and the ambition, you could replace your existing tabernacle with a custom made pivoting one. Find a piece of heavy gauge aluminum channel that you can cut into a shape similar to the C-22 tabernacle shown in the picture above. The channel should be just wide enough for the mast to sit into and the height a couple of inches. Cut slots in the sides for the through bolt to slide up and down. Cut the channel long enough and drill holes in the bottom of the channel to fit your existing deck bolts.

Then drill a hole through the base of the mast to accept the through bolt. It should be close to the bottom of the mast, 1/4″-1/2″ from the bottom. Angle the aft edge of the end of the mast so that it will rotate without binding in both directions. As it rotates backward during unstepping, the bottom end of the mast and the through bolt should ride up in the slots. Put a wingnut on the end of the through bolt for easy removal and you’ve got a pivoting mast.

If you don’t have the resources to make one yourself, maybe you can find a friend or a metal fabricator to help.

Good luck with your projects and thanks for your question! $tingy

When installing the gin pole hinge bracket you drill through the cabin roof. Have you experienced any water penetration through this hole?

I sealed the plate and hole perimeters with butyl tape, so no problems.

Wow! Love the post and videos!! So clear and easy to follow. I’m going to try this for my Columbia 8.3. I tried to follow you but got an error code. Can you manually add me, please?

Please try following again and if the error repeats, send me the text or a screenshot of the error so I can investigate.

My Venture 21 tabernacle and mast look like yours (sans the plate for your swivel blocks) and I have often wondered if there is wear on the trailing edge of the mast foot after repeated raising/lowering? Or does yours have some reinforcement?

Also, have you ever noticed the boom baby stays pulling too much on the stantions? I wonder if mounting the ropes at the base would be less apt to damage them if the mast were to go somewhat off-center (to the exrent the upper shrouds allowed)?

Love your site. I shared the 2017 DIY competition on Small Craft Advisor Magazine’s Facebook page and I noticed the 10 most popular projects link…most of which are on my to-do list!

There is a tiny bit of wear after 36 years but not enough to matter. Tying the baby stays to the stanchion bases would be more solid but then their pivot points would be too low. The reason that I tie them up at the top of the stanchions is so that the baby stays keep in relatively constant tension throughout the range of motion of the mast/boom. They’re almost perfectly aligned with the tabernacle. The stanchions aren’t in much danger because the boom doesn’t weight much and it can’t wander very far at all since it’s held in tension between the forestay (running aft) and the main sheet (running forward). They really just help to hold the boom vertical while you’re setting the system up until you begin to raise the mast. The mast can wander side to side some until its raised about halfway, then the upper shrouds come taught and keep it centered.

Thanks for the share!

Your site has been a tremendous help and inspiration for me and my 1988 Cat 22. My mast step has welded loops fore and aft. Can you suggest a structurally sound way to secure the boom to the loop for lifting/lowering?

Link showing the step: http://www.catalinadirect.com/index.cfm/product/345_18/mast-step-c-22-cp-22brcp-18-wwelded-vang-loop.cfm

Hello, KGUNN

Since the loop is perpendicular to the line of the mast/boom rotation, it won’t work well using only off the shelf parts. I suggest you consider mounting a tang like the Garhauer BT-1 to the bottom of the mast instead. You can pin the boom to it similar to how I do it to my bracket. The boom will then rotate with the mast as it raises and lowers.

Great suggestion. Thanks!

Hmmm, this asks more questions for than answers. I don’t have the lower stays, nor do I have any of the attachment point on the mast that I can see. The thing is the boat is smaller 20′ vs 22′ I have no lifelines nor a rear rail, walking down the side of the boat would be a challange, never mind running lines while doing so. The mini stays have no place to attach to. Not sure how to go about raising the mast without help…even with this setup…

A smaller sailboat could indeed be trickier to step the mast single-handed since it has less rigging to aid the process. If you’re not committed to perfecting a single-handed technique, I’d suggest you consider a two-handed process with one crew member in the cockpit to steady the mast laterally while the second crew member pulls the mast up by the forestay or foresail halyard from the bow or on the ground in front of the bow. A mast crutch would also help in that case. Otherwise, you might be looking at extensive fabrications or commercial mast stepping hardware with a winch.

Where there’s a will, there’s a way!

How could your system be used with a furling 150 genoa on a Catalina 25?

Hello, Thomas

It could be used in a similar way on your C-25 with a couple of adjustments. First, your mast is longer and heavier than a C-22 so I would always use the boom as a gin pole. You’ll need the leverage for the extra weight, especially with the addition of the furler. Second and more importantly, you’d need to lift the furler as well as the mast somehow. I’d suggest using a main or spinnaker halyard to hold the mast and furler together. Wrap it around them from top to bottom before you lower the mast, then handle them as one unit until after you raise the mast again and unwrap the halyard to reconnect the forestay/furler. Use the jib halyard with its working end securely tied off instead of the forestay to connect the masthead to the boom/gin pole. The rest of the process would work the same.

Stay tuned because I’ll be publishing a post soon about choosing and using a furler with a trailerable sailboat.

Appreciate your reply Stingy. I need to carefully review your technique but it seems one’s boom would remain upward; although I’m sure you lower it when finished? Sorry for my ignorance. I’m also looking at the idea from the clever MacGregor 26 mast raising pole that uses a winch on the pole with baby stays with a special one to automatically keep the lowered furler up off the deck. I read about it on TropicalBoating ( https://www.tropicalboating.com/2010/04/the-perfect-solo-mast-raising-system-for-small-sailboats ). I’ll have a look at your mast crutch but I can’t use the gudgeons for the rudder as I’ll need to motor over to the Cave Run Lake (KY) boat launch for the haul out. Thanks!!

Winch-powered mast raising systems are a good choice for owners with impaired physical abilities. I might have to resort to one as I get older and am not able to do everything I once could. Beats giving up sailing!

One needs to attach a mast bail with the MacGregor 26 solo mast stepping system. I’m reluctant to drill into the mast though. This is my first cruiser (purchased in July) and I’ve much to learn from your blog. I was only introduced to sailing two years ago when I bought a Sunfish.

My C-25 teak companionway/hatchboards need replacement after 20 years, probably all standing rigging needs replacement even though it all looks fine at deck level (in the Lake continuously since ‘08), etc., etc. I pulled two through hull Airmar transducers out to check them and found only thin layer of algae on them – tells me the lake water has been very clean. The old KVH display is dead so I’ll switch it out (plugging holes with marine plastic and epoxy) with a new RayMarine i40.

I see that the boom is removed of course in your video. I also see the stress on the mast crutch essentially dictates one use the transom gudgeons for support. I had thought I could use 1” pipe secured to the stanchions but then there would not be enough telescoping height available either. You’ve devised a very clever approach- I’ve never remounted my boom so will need how I can attach it to the fore ring on the step plate.

You might consider modifying my crutch design so that the bottom end rests in the cockpit sole forward of the transom instead of on the rudder gudgeons. It would probably need additional support or to be fastened to the mast to keep it from falling over. Offset to one side a little, you should still be able to use your rudder to steer. That, or use the outboard tiller instead of the rudder to get to the ramp if you can. I do that sometimes.

Just what I have been looking for to give me some information to guide me in raising and lowering the mast for maintenance on my 26 foot Grampian without the expensive use of a crane this spring.

Hi, I like your idea of the mast raising system without a gin pole. Does your block & tackle include a ratchet or brake? Thanks!

Hello, Laura

Since I use my mainsheet tackle, no, but if you want to use a separate tackle, that would be a good idea.

Thanks, $tingy

Sure beats my system of using 2 sons to help out, they’re never around when you need them !

Thanks for the video on the no pole lift, that’s pretty much how I need to do it though I usually am working on the hard before getting a lift in.

I have tried raising the mast as you show in the video. I have the same quick release. But when I try to lift the mast with the forstay can’t do. I’m wondering maybe your mast is lighter or do I have the wrong set up to raise mast. I have the mast step which I can raise for a better angle…but it’s not happening.

Hello, Mark

Are you using a gin pole or trying to lift it only by the forestay? Either way, it takes quite a bit of strength to get the mast up that first few feet since you’re not pulling directly vertically on the masthead. If you’re not able to do it by yourself, you might need a helper for at least that part of the setup.

Dear sir My name is Mark Monteverdi. I have followed your web site for a while…and always turned out good. I have looked at the mast rising video countless times. I have the quick release for the shrouds. I’m guessing you are using a basic vang ? Well either I’m very weak or i have the vang set up incorrect or my mast is made of different material …when i go to raise my mast it will fall off to one side it just feels as though I’m pulling a truck up a hill. If you would be kind enough to send a pic of what ever type of pulley system i would greatly appreciate that very much. It’s hard to get any one to go sailing with me and that’s more just so i have some one to push and one work the winch. Thank you Mark

I’m sorry to hear you’re having trouble. When raising or lowering my mast, it too will tend to swing to one side or the other until it’s about half way up and the upper shrouds tighten and hold it centered the rest of the way up. That’s why I always have at least one hand on the mast to keep it centered during the lower half of the lift. I use the standard C-22 main sheet tackle which has a 3:1 mechanical advantage. You could use a stronger tackle (try 4:1) if you need the additional lifting power. You can see the whole main sheet in the video in Quit Spending Setup Time on Turnbuckles .

Hope that helps, $tingy

Hi Stingy Sailor, First of all, thanks for all your tips, tricks, and videos. Your site is awesome and very helpful! I have a C-25 with swing keel so most of all your tips are applicable, very nice, and handy. I really like your mast securing device located at the bow for trailering; easy and simple. I was wondering if you do have the drawings available for it so I could use it to build my own? Thanks! Alex

I did not make a fabrication drawing for the pulpit saddle because of the complex angles of the railing cutouts. Most readers wouldn’t be able to cut them accurate enough, so it’s a trial and error fit. Lay your material centered across the top of the pulpit, trace the railing edges onto the underside of the material, then cut a little at a time until the saddle sits down securely over the rails. Do the same with the mast on top of your material and you’re done.

Good morning, what a beautiful boat you have there ! that is an ingenious way to raise a mast,nice work ! I am curious about what the black,plastic/rubber item is that looks like it’s attached to the stern rail by the mast crutch @ 2:45 of the first video Please respond because my curiosity is killing me because I don’t get it. Thanks, Mick

You can read all about it in Add a Solar-Powered Flood Light in Your Cockpit .

Hi! I just subscribed to your blog, and I’d like the instructions for building a mast crutch like yours. Wasn’t sure whether that would be sent out automatically, or whether I needed to specifically ask for them. Thanks!

Lenny, You can find a dimensioned drawing of the mast crutch on my Downloads page if you’re a subscriber. The password to open that page was sent to you when you subscribed. $tingy

Leave a comment Cancel reply

This site uses Akismet to reduce spam. Learn how your comment data is processed .

- Already have a WordPress.com account? Log in now.

- Subscribe Subscribed

- Copy shortlink

- Report this content

- View post in Reader

- Manage subscriptions

- Collapse this bar

Practical Boat Owner

- Digital edition

Do-it-yourself mast stepping

- Rupert Holmes

- May 23, 2024

If you’re thinking of hiring a boatyard crane to step your mast, why not consider this low-tech, low-cost alternative? Rupert Holmes shows how it’s done

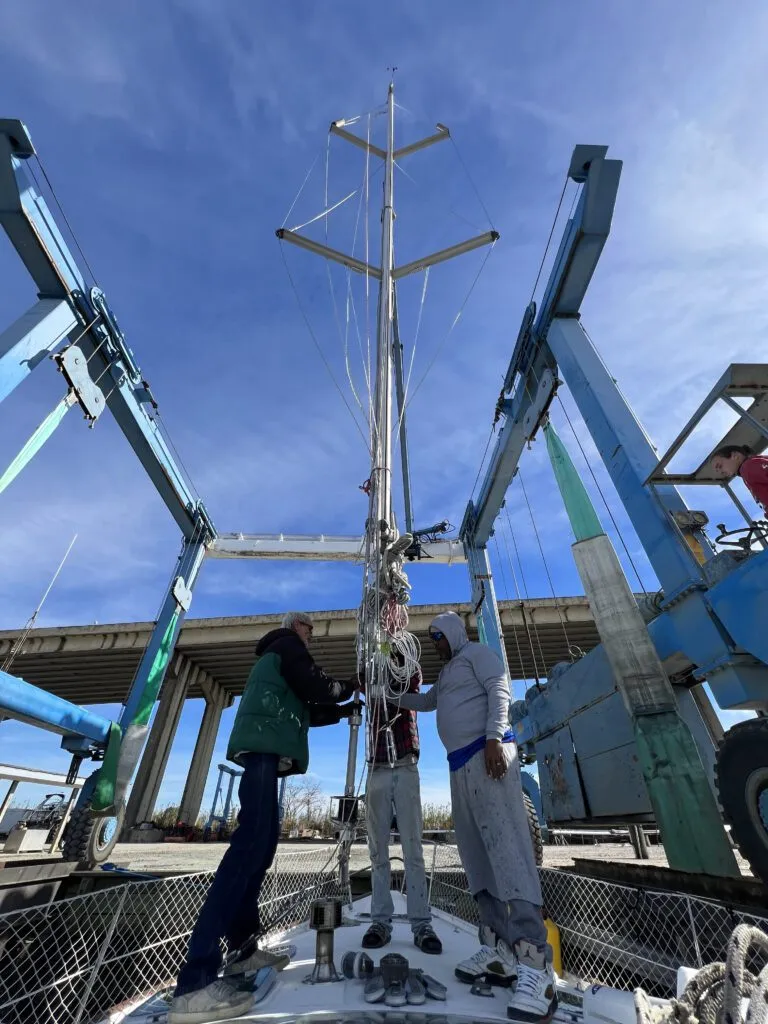

Raise or lower your mast with a boat either side and a few willing helpers

Mast stepping without a crane may sound impossible – but it’s quite straightforward given a couple of willing friends with boats and reasonably flat water.

The basic idea is to raft your boat between the other two, and use their halyards to lift your rig .

With practice, little more than half an hour is needed: this technique is standard practice among charter fleets in the Eastern Med , where often there are no cranes available if mid-season repairs are needed at short notice.

However, I’ve never seen this method employed anywhere in the UK or other parts of northern Europe.

Yet it could be really cost effective for clubs that store yachts on the hard over the winter, as a crane only needs to be hired to put the first two rigs up.

Indeed, if two of the boats have tabernacles , it may be possible to step the masts of the entire fleet without recourse to a crane.

Of course, mast raising is never without risk, even using a crane, so it’s important to allow plenty of time – especially on a first attempt – and approach the task in a logical and organised fashion.

Mast stepping: Weight worries

An 11m (36ft) rig for a typical 9-10m (30-34ft) cruiser weighs about 75kg (165lb), maybe a little more if there are halyard winches mounted on the spar.

That’s around the same weight as hoisting an average-size person aloft, but with the load spread between two rigs, of course.

This means hoisting the spar is well within the design capabilities of the rig of a similar-size or larger vessel and does not need to be a strenuous operation.

Raft the three boats together, with yours in the middle.

Here we’re raising the mast on my own Discovery 3000, Ammos .

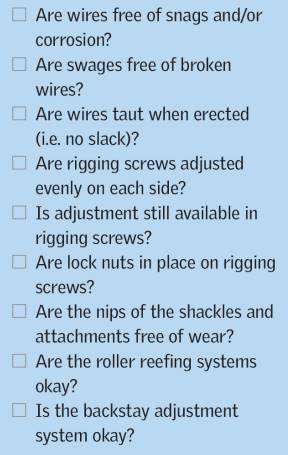

1. Tie halyards from the neighbouring yachts under your spreaders

We pointed her in the opposite direction to the others, enabling the main halyards of the outer vessels to be used, but you could also use spinnaker halyards, especially if they are fitted with a swivelling pulley at the masthead, in which case it’s best to have all three boats facing in the same direction.

Tie a halyard from each of the other boats under your spreaders, and include a retrieval line so you can get the halyards back down once the mast has been stepped.

Never be tempted to use a snap shackle to secure the halyards – although generally reliable they can fail without warning under load, and the danger of that happening when supporting the mast is too great a risk.

A large bowline tied in the end of the halyard is a much more secure method.

Don’t worry if the halyards on the neighbouring boats are a little too short – simply attach an extra length of line to make up the difference and form a strop.

Also, securely tie a guide rope around the mast foot – this is to control the heel of the rig as it’s lifted.

Rig raising

Simultaneously hauling the halyards of the neighbouring boats will not lift the rig.

You’ll need a couple of people on the deck of your boat to guide and control the spar as well.

If it’s a single-spreader mast, as was with Ammos, it will initially rise almost horizontally, but as the rig gains altitude, the foot of the mast can be guided towards the mast step on deck, or the partners if it’s a keel-stepped rig.

2. Start hoisting the rig – when doing it the first time it helps to have a few extra people on your deck to lend a hand – and allow plenty of time

In an ideal world, each of the halyards would be hauled at the same rate so that, once the mast is standing more or less upright, it is always vertical in the athwartship plane.

However, this is rarely the case so you’ll need to check on the angle of the rig as it’s lifted, directing each winch grinder as necessary to keep it in line.

3. As the rig rises, you can start walking the foot of the mast forwards, towards the mast step

With a two-spreader rig, it’s best to put the strop below the top spreaders if possible.

This will lift the top of the mast first, so the heel will then need to be ‘walked’ along the deck of your boat towards the mast step as the rig is lifted.

Three-spreader rigs can be lifted by the upper or middle spreaders – the former is easier, providing the rigs of the boats assisting you are tall enough.

Delicate stage

Locating the mast on its step is the most precise stage of the operation, requiring good communication between the crew on your boat, who are manoeuvring the foot of the mast into place, and the halyard operators manning the winches on the adjacent yachts.

The rig needs to be lifted until it’s just clear above the mast step – around 2cm-3cm (an inch or so) of clearance is fine.

Once it’s in position, the halyards can be eased a fraction – tell each operator exactly how much – until the rig is sitting firmly on the mast step, still supported by the two halyards.

4. The rig rarely goes up exactly vertically, but that’s easy to tweak by adjusting the load on the two halyards

If you have a keel-stepped mast it’ll have to be carefully lowered through the partners to the keel below.

Once the mast is correctly located, put each of the cap shrouds into their bottle screws, spinning the first one by only a couple of turns to give the maximum chance of settings its opposite number connected.

If the rig is canting over to one side and it’s not possible to connect the second cap shroud to its bottlescrew, the halyard on the boat on the opposite side to that shroud is a little too tight.

Ease the halyard a fraction, then take up the slack on one of the other supporting boats, being careful not to lift the rig off the mast step.

With the mast held aloft it’s time to connect the cap shrouds

Once both shrouds are connected, and tensioned enough for the threads to be fully covered, connect the forestay and backstay.

If the rig is not sufficiently upright in the fore and aft plane, and one won’t reach its bottlescrew, one of your own halyards can be taken down to a suitably stout deck fitting and tensioned to tilt the mast in the correct direction.

Once the forestay, backstay and cap shrouds are connected their bottlescrews should be wound up hand-tight – this will secure the rig sufficiently for the supporting halyards to be released and returned to their respective boats.

After that, the lower shrouds and babystay can be connected.

Tensioning and tuning

Next tension the rig to its normal settings, or as close as you can manage, using a pair of well-fitting spanners to turn the bottlescrews once they’re too tight to wind by hand.

Don’t be tempted to turn a bottlescrew under tension by using a screwdriver poked through the body as a lever – they’re not designed for those sort of forces.

On larger boats it may not be possible to achieve the full tension needed without going sailing – this allows the lee shrouds to be tensioned when they are slack.

If you do this and plan to leave the bottlescrews unpinned while adjusting the rig, each pair of cap and lower shroud bottlescrews can be tied together with line to prevent them unscrewing.

Lowering the rig

It’s also possible to lower a mast by reversing this method. Less muscle power is needed, but it’s still important to take care.

Start by tying a halyard from each of the supporting boats under the spreaders – making sure these are outside the lower shrouds and babystay – then tension the halyards to support the rig.

At this stage, the rigging can be disconnected. Ensure you record the number of turns on each bottlescrew so the rig can be tuned with the same settings next time it is stepped.

Continues below…

How to set up your rig: tension your shrouds on masthead or fractional

How to set up your rig: tension your shrouds on masthead or fractional If boats were cars, many of those…

Rig tuning: a practical guide for sailors

Correct rig tension will maximise the efficiency of your boat’s sails as well as reduce stresses on the mast. David…

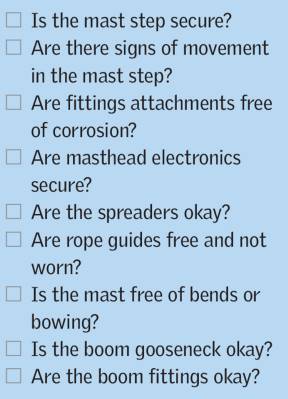

Rebuilding a damaged mast step

Rupert Holmes repairs a compressed water-damaged mast step – a common problem for boats with a deck-stepped mast - and

Coping with a dismasting & rig checks

Faced with a sudden dismasting in 40-knot gusts, Rupert Holmes explains how he and his crew saved his boat, and…

It also helps to clean and oil the threads before starting work.

The critical part is when the rig lifts off the mast step.

The mast heel will start to swing, especially if it’s a single spreader rig that will want to lie horizontally from the strop, though it’s no different in this respect to using a crane.

It’s worth having two people standing opposite each other, both holding a line to control the mast foot.

That way, they can arrest its progress, whichever direction it wants to move.

Once the rig has been lifted off its step, all that’s needed is the halyard operators on each of the adjacent boats to coordinate lowering the spar to the deck.

Enjoy reading Do-it-yourself mast stepping?

A subscription to Practical Boat Owner magazine costs around 40% less than the cover price .

Print and digital editions are available through Magazines Direct – where you can also find the latest deals .

PBO is packed with information to help you get the most from boat ownership – whether sail or power.

- Take your DIY skills to the next level with trusted advice on boat maintenance and repairs

- Impartial in-depth gear reviews

- Practical cruising tips for making the most of your time afloat

Follow us on Facebook , Instagram, TikTok and Twitter

- Navigating the High Seas: A Comprehensive Guide to Sailboat Masts

Sailboat masts are the unsung heroes of the sailing world, silently supporting the sails and ensuring a smooth journey across the open waters. Whether you're a seasoned sailor or a novice, understanding the intricacies of sailboat masts is essential for a safe and enjoyable voyage. In this comprehensive guide, we will delve into the world of sailboat masts, discussing their types, maintenance, and everything in between.

Types of Sailboat Masts

Sailboat masts come in various configurations, each with its advantages and drawbacks. The two primary types are keel-stepped and deck-stepped masts.

Keel-Stepped Masts

Keel-stepped masts are the most common type, extending through the deck and resting on the boat's keel. They provide excellent stability and are suitable for larger sailboats. However, they require careful maintenance to prevent water intrusion into the boat's cabin.

Deck-Stepped Masts

Deck-stepped masts rest on the deck of the boat, making them easier to install and remove. They are commonly found on smaller sailboats and are more forgiving in terms of maintenance. However, they may offer slightly less stability than keel-stepped masts.

Components of a Sailboat Mast

To understand mast maintenance better, it's essential to know the various components of a sailboat mast. The key parts include the masthead, spreaders, shrouds, and halyard sheaves.

The masthead is the topmost section of the mast, where the halyards are attached to raise and lower the sails. It also often houses instruments such as wind indicators and lights.

Spreaders and Shrouds

Spreaders are horizontal supports attached to the mast to help maintain the proper angle of the shrouds (cables or rods that provide lateral support to the mast). Properly adjusted spreaders and shrouds are crucial for mast stability and sail performance.

Mast Materials: Choosing the Right One

Sailboat masts are typically constructed from three primary materials: aluminum, wood, and carbon fiber. Each material has its unique characteristics and is suited to different sailing preferences.

Aluminum Masts

Aluminum masts are lightweight, durable, and relatively easy to maintain. They are commonly used in modern sailboats due to their cost-effectiveness and longevity.

Wooden Masts

Wooden masts, while classic and beautiful, require more maintenance than other materials. They are best suited for traditional or vintage sailboats, where aesthetics outweigh convenience.

Carbon Fiber Masts

Carbon fiber masts are the pinnacle of mast technology. They are incredibly lightweight and strong, enhancing a sailboat's performance. However, they come at a premium price.

Mast Maintenance

Proper mast maintenance is essential for safety and longevity. Regular cleaning, inspection, and addressing minor issues promptly can prevent costly repairs down the line.

Cleaning and Inspection

Regularly clean your mast to remove salt, dirt, and grime. Inspect it for signs of corrosion, wear, or damage, paying close attention to the masthead, spreaders, and shrouds.

Common Repairs and Their Costs

Common mast repairs include fixing corroded areas, replacing damaged spreaders, or repairing shrouds. The cost of repairs can vary widely, depending on the extent of the damage and the materials used.

Extending the Lifespan of Your Mast

Taking steps to prevent damage is essential. Avoid over-tightening halyards, protect your mast from UV radiation, and keep an eye on corrosion-prone areas.

Read our top notch articles on topics such as sailing, sailing tips and destinations in our Magazine .

Check out our latest sailing content:

Stepping and Unstepping a Mast

Stepping and unstepping a mast is a crucial skill for any sailboat owner. This process involves removing or installing the mast on your boat. Here's a step-by-step guide for safe mast handling.

Step-by-Step Guide for Safe Mast Handling

- Gather the necessary tools and equipment.

- Disconnect all electrical and rigging connections.

- Use a crane or mast-stepping system to safely lower or raise the mast.

- Secure the mast in its proper place.

- Reconnect all electrical and rigging connections.

When and Why to Unstep a Mast

You may need to unstep your mast for various reasons, such as transporting your sailboat or performing extensive maintenance. It's crucial to follow the manufacturer's recommendations and ensure a safe unstepping process.

Sailboat Mast Boot: Protecting Your Mast

A mast boot is a simple yet effective way to protect your mast from water intrusion and damage caused by the elements. Here's what you need to know.

The Purpose of a Mast Boot

A mast boot is a flexible material that wraps around the mast at the deck level. It prevents water from entering the cabin through the mast opening, keeping your boat dry and comfortable.

Installing and Maintaining a Mast Boot

Installing a mast boot is a straightforward DIY task. Regularly inspect and replace it if you notice any signs of wear or damage.

Replacing a Sailboat Mast

Despite your best efforts in maintenance, there may come a time when you need to replace your sailboat mast. Here's what you should consider.

Signs That Your Mast Needs Replacement

Common signs include severe corrosion, structural damage, or fatigue cracks. If your mast is beyond repair, it's essential to invest in a replacement promptly.

The Cost of Mast Replacement

The cost of mast replacement can vary significantly depending on the type of mast, materials, and additional rigging needed. It's advisable to obtain multiple quotes from reputable marine professionals.

Yacht Masts: Sailing in Style

For those looking to take their sailing experience to the next level, upgrading to a yacht mast can be a game-changer.

Differences Between Sailboat and Yacht Masts

Yacht masts are typically taller and offer enhanced sail performance. They are often equipped with advanced rigging systems and technology for a more luxurious sailing experience.

Upgrading to a Yacht Mast

Consult with a marine professional to determine if upgrading to a yacht mast is feasible for your sailboat. It can be a significant investment but can transform your sailing adventures.

Sailboat Mast Steps: Climbing to the Top

Mast steps are handy additions to your mast, allowing easier access to perform maintenance or enjoy panoramic views. Here's how to use them safely.

Using Mast Steps Safely

Always use proper safety equipment when climbing mast steps. Make sure they are securely attached to the mast and regularly inspect them for wear or damage.

The Advantages of Mast Steps

Mast steps provide convenience and accessibility, making sailboat maintenance tasks more manageable. They also offer an elevated vantage point for breathtaking views while at anchor.

Mast Maintenance Tips for Beginners

If you're new to sailboat ownership, these mast maintenance tips will help you get started on the right foot.

Essential Care for First-Time Sailboat Owners

- Establish a regular maintenance schedule.

- Seek advice from experienced sailors.

- Invest in quality cleaning and maintenance products.

Preventing Common Mistakes

Avoid common pitfalls, such as neglecting inspections or using harsh cleaning agents that can damage your mast's finish.

Sailing with a Mast in Top Condition

A well-maintained mast contributes to a safer and more enjoyable sailing experience. It enhances your boat's performance and ensures you can rely on it in various weather conditions.

How a Well-Maintained Mast Improves Performance

A properly maintained mast helps maintain sail shape, reducing drag and improving speed. It also ensures that your rigging remains strong and secure.

Safety Considerations

Never compromise on safety. Regularly inspect your mast, rigging, and all associated components to prevent accidents while at sea.

Sailboat masts are the backbone of any sailing adventure, and understanding their intricacies is crucial for a successful voyage. From choosing the right mast material to proper maintenance and upgrading options, this guide has covered it all. By following these guidelines, you can sail the high seas with confidence, knowing that your mast is in top condition.

So what are you waiting for? Take a look at our range of charter boats and head to some of our favourite sailing destinations.

I am ready to help you with booking a boat for your dream vacation. Contact me.

Denisa Nguyenová

- Forums New posts Unanswered threads Register Top Posts Email

- What's new New posts New Posts (legacy) Latest activity New media

- Media New media New comments

- Boat Info Downloads Weekly Quiz Topic FAQ 10000boatnames.com

- Classifieds Sell Your Boat Used Gear for Sale

- Parts General Marine Parts Hunter Beneteau Catalina MacGregor Oday

- Help Terms of Use Monday Mail Subscribe Monday Mail Unsubscribe

Un-stepping and re-stepping a mast.

- Thread starter Damifudo

- Start date Nov 6, 2015

- Tags mast stepping

- Catalina Owner Forums

- Catalina 30

I am running through the jobs I need to do, on the new to us Catalina 1988 Tall rig, One need is to remove the mast and do a complete check and replacement of the standing rig. I have never done this but I am a bit do it yourself person and I have access to a bucket truck from work that the bottom of the bucket goes 37 feet and the lifting capacity is 300 lbs. Would you think this could handle a mast removal and install or should I plan on a crane. The nice thing with the bucket truck is you can get back up the mast to unstrap it. I hope to do this next fall unless someone tells me I need to replace some shrouds sooner rather than later. I am surprised there is no videos on youtube of someone doing a mast stepping on a Catalina 30. If you have any please share them. List for a mast service that I am aware of at this point. 1. new standing rig. 2. new antenna wires and maybe antenna. 3. inspect and replace mast head pulleys as needed 4. seal around mast base 5. Wind vane or Garmin G wind if I have any $ left.

Unless you have detected corrosion damage or broken strands or have knowledge of any accidental damage to the rigging I would not decide to replace it until a thorough inspection was concluded. I'm assuming the rigging is original and is 27 years old. If in doubt get a rigger to do the inspection. There is a maxim about boats in general and that is "if it ain't broken, don't fix it" as there is a significant risk when tinkering with something that something else will break or will be weakened to where it may need a future repair in a short time. All the other maintenance items that you have listed are usually conducted from the crunching comfort of a bosum chair and do not require dropping the mast. Replacing the standing rigging in materials alone is expensive so if after a thorough inspection you find that there is no need to replace it at this time you may have the money, even after paying a rigger for the inspection, to get that coveted Garmin G Wind. I don't really know the capabilities of the bucket truck so I will not comment on its use but if this is the first time that you could be dropping the mast why not pay to have the marina or yard do it and watch and learn. I imagine you will be hauling the boat out anyway so just pay a little more and let them do it. It is not rocket science but it does have it's doe's and don'ts.

We had to take our mast down, due to leaks in the cabin through the compression post, and had a rigging spe ialist come out to assess. After 27 years in service, I would just replace the main shrouds. Also, check the bobstay. Ours was broken, but there was virtually no way of knowing it until i took of the old one. Just lucky! Also consider replacing lights, with either LEDs or newer ones...again, if needed. We also replaced jib halyard and ran a new coax cable. After that many years, these things are at or beyond life expectancy. I also agree that once you start touching things, you will end up replacing them. We have an 85 tall rig as well.

Damifudo said: I have access to a bucket truck from work that the bottom of the bucket goes 37 feet and the lifting capacity is 300 lbs. Click to expand

Richard Bryer

Interesting- the boom truck thing. Our club bought a polcat boom truck several years ago just for that reason- to remove masts. I don't know the weight capacity but it handles the heaviest masts in the club- including a Whitby 45. If the weight capacity was more than 300 lbs I would say it is a good solution. The bucket is removed on ours and the height is probably more than 37 feet- however we lift with a line around the mast just above the balance point and tied off at the bottom. This means on my 45 foot mast the boom is probably about 23 feet above the deck/ ground level. It works well- we remove masts each fall and raise them each spring.

Richard Bryer said: Interesting- the boom truck thing. Our club bought a polcat boom truck several years ago just for that reason- to remove masts. I don't know the weight capacity but it handles the heaviest masts in the club- including a Whitby 45. If the weight capacity was more than 300 lbs I would say it is a good solution. The bucket is removed on ours and the height is probably more than 37 feet- however we lift with a line around the mast just above the balance point and tied off at the bottom. This means on my 45 foot mast the boom is probably about 23 feet above the deck/ ground level. It works well- we remove masts each fall and raise them each spring. Click to expand

The line to hoist the mast is simply run under itself at the hoist point and then run straight down the mast and tied around it under the gooseneck fitting to keep it from sliding up. It does require hoisting someone up the mast to the hoist point in a bosun's chair when taking the mast down. When raising the mast the line can be pulled away from the mast with the polcat boom after untieing the bottom. There are ways of attaching the sling line without having to climb or be hoisted- Claude do you still have your documentation of how you do it?

To step and unstep the mast on my Cat 30TR we make up a sling using a large bowline sufficiently loose to allow it to slide up the mast to the required height just below the spreaders. Another loop in the line attaches to the hook or whatever is used to raise the line. From the loops the line descends to be secured at the bottom of the mast within easy reach. When re positioning the mast the loop will drop down to the base once the shrouds have been secured.

Claude L.-Auger

Richard Bryer said: The line to hoist the mast is simply run under itself at the hoist point and then run straight down the mast and tied around it under the gooseneck fitting to keep it from sliding up. It does require hoisting someone up the mast to the hoist point in a bosun's chair when taking the mast down. When raising the mast the line can be pulled away from the mast with the polcat boom after untieing the bottom. There are ways of attaching the sling line without having to climb or be hoisted- Claude do you still have your documentation of how you do it? Click to expand

Attachments

- Installing sling for un-stepping of mast on B & R rigging.pdf 1.8 MB Views: 1,398

Elysium_Van_Isl

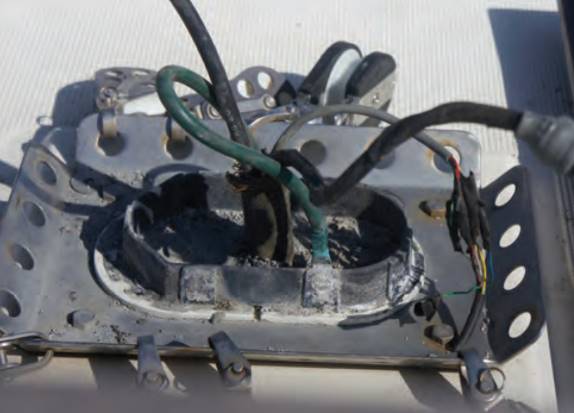

Hey, Im late getting on this thread, but I'm getting set to pull he mast on my standard rig this winter. I'll be using the marina's staff and crane to lift the mast, so am less concerned with the 'equipment' and more with the process. The internal wires on my '82 all seem to go down into the deck where they're laminated into the headliner. When the stick is lifted a bit, what's to be expected? Some type of quick-connect on the wires just before they enter the deck, or am I going to be cutting? Thanks!

Elysium_Van_Isl said: Hey, Im late getting on this thread, but I'm getting set to pull he mast on my standard rig this winter. I'll be using the marina's staff and crane to lift the mast, so am less concerned with the 'equipment' and more with the process. The internal wires on my '82 all seem to go down into the deck where they're laminated into the headliner. When the stick is lifted a bit, what's to be expected? Some type of quick-connect on the wires just before they enter the deck, or am I going to be cutting? Thanks! Click to expand

From what I understand there is a connector.

The mast is more than 300 lbs and I am guessing it's taller than 37 ft.

We step and unstep every season because the top of the crane at the launch is too low to allow the mast to remain standing. (most of the boats at the marina are powerboats) As has been pointed out, once it is lifted it must steered so that the foot of the mast goes forward to a support resting on the pulpit, and the mast head rests on a support resting on the pushpit. Accomplishing this is always an adventure, and I never relax until it is resting horizontal on the two supports. However often you choose to step and unstep it, disconnecting and connecting the wiring at the mast can be a struggle or at the very least inconvenient. Years ago, probably after the first year of stepping and unstepping, I decided to do something about the spaghetti that gets disconnected at unstepping, and at stepping,reconnected and crammed into the mast just before it is set onto the mast step. I drilled out the hole through the step angling it so that it would pass through into the top of the cabin at the junction of the ceiling and the port bulkhead on the salon side. I then fitted a 1" piece of PVC pipe into the hole,letting the top of the piece project above the step 1" or so, sealing it with silicone to prevent leakage. I then built a teak junction box next to the mast post to conceal the connections. As I recall, there was enough wire inside the mast to feed it through the tube and into the junction box. If not you could splice and extend the wires. The VHF wiring uses the existing connectors , the mast head instrument wiring and all the lighting are connected to a terminal block. Before the mast is unstepped, everything from the junction box into the mast is disconnected. When the mast is raised, all the mast wiring is pulled up and out and stuffed into the foot of the mast. After the first year I stuffed towels into the mast foot and cut a bleach bottle up to make a cap... the starlings had made a comfortable home inside and did not install indoor plumbing... Stepping is simply the reverse, When the mast is raised into position, replace the wiring through the conduit and pull out the slack from below as the mast is lowered into place. Reconnect at your leisure after the mast is stepped and a beer has eased the tension. Hope this isn't too much information. I'm not a camera person, so I use a thousand words to create a picture ;>)

How much would you say the mast and rigging weigh?

Damifudo said: How much would you say the mast and rigging weigh? Click to expand

25yearslater

I might be able to help with this. I shipped my mast to Charleston Spar for the reanodize and powdercoat. Because I was using USF Holland the weight had to be determined. The mast without rigging was 105 LBS. This is 33' 1/2". Masts are relatively light being extruded aluminum. Here is a link to Rig Rite and the weight per foot table for masts. If your mast is different return to spars and click on the appropriate mast and section. http://www.rigrite.com/Spars/Spartan_Spars/SPARTAN.html

Damifudo, you are going to need help no matter what technique you use. You would be well served to find some people who have experience at this on boat's your size or bigger. And since there's a risk of injury there should be insurance for your helpers. While friends may be willing and able to help, if they are injured and can't work, or worse, you will have a very bad situation. From a practical point of view, this may mean paying the yard to do it would be wise.

When the mast comes down from a fully rigged bout it has all the rigging hard and soft along with all the hardest and antennas and electronic accessories mounted and can be quite heavy so always allow for that then double the weight to creat a Safty factor and use a crane that can handle twice that amount you never know when the weight is on the hook ..... There may be a hard blow start up when you are suspending the weight un attached with only a tag line and that can get Harry as hell till you land the load

A lot of good advice here. I would certainly second the thought of having someone help who has done it before. Or go and help a couple of people do theirs. It is a good idea to know what to expect. I have known a couple of masts at our club to topple overboard during the process and it is very scary and dangerous. Don't rush the process and pick as calm a day as possible. Yours is a deck stepped mast and there should be a connector for each of the wiring cables under the mast. You need to lift it a few inches to see- there is probably enough slack to lift it about a foot then reach under and disconnect. That is the part I did NOT like- the reaching under. I cut a small- about 2"X4" in the side of the base and made a ss cover to screw on it. I pull the cables out and disconnect before hoisting the mast- then all you have to do is stuff the boat end back in after lifting a bit. When putting the mast back up, leave the mast ends out the opening and push the boat ends up and out the opening when you have the mast a foot or so off the base. Minimizes the hand time spent under the hoisted mast. If you look at Fred Ficarra's rebuild site for Epitome in the owner mods section here you should be able to find a picture of the opening and cover panel he made on his mast

- This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register. By continuing to use this site, you are consenting to our use of cookies. Accept Learn more…

- LNG Fundamentals

- LNG Shipping Knowledge

- Gas Tankers Familiarisation

- Prevention of Rollover in LNG Ships

- Rules for Ships Carrying Liquefied Gases

- Conversion of Ship to LNG as Fuel

- LPG Tanker Practice

- LNG Bunkering Operation

- Simulation Model for an LNG ferry

- Gas Production Operations

- Liquefied Gas Handling Principles

- Effects of Fire on LNG Carrier Containment Systems

- Transportation of Liquefied Natural Gas

- Gas Carrier Course

- Ship to Shore Access

- LNG Trade and Transport

- Quality Control of Cargo Handling Work in LNG Carriers

- Training for Liquefied Gas Tanker Cargo Operations

- ESD Arrangements for Liquefied Gas Carriers

- Types of ships

- Rules for Safe Carriage of Cargoes by Sea

- How to Buy the Best Sailboat?

- Sell Your Boat in 30 Days

- RONOMAR GMDSS Course

- CES/CBT tests

Masts and Rigging Systems for Sailing Ships

Masts and rigging are essential components of sailing vessels, serving crucial roles in both the structure and functionality of the ship. The masts are the vertical poles, typically made of wood or metal, that rise from the deck of the ship and support the sails. They come in different types depending on the size and design of the vessel, including the mainmast, foremast, and mizzenmast. These masts must be strong and flexible enough to withstand the forces exerted by the wind on the sails. The height and placement of the masts are meticulously planned to optimize sail efficiency and balance the ship’s stability.

Standing rigging

Running rigging, lifting/hauling systems.

Rigging refers to the complex system of ropes, cables, and chains used to support the masts and manipulate the sails. There are two main types of rigging: standing rigging and running rigging. Standing rigging consists of the fixed lines that hold the masts upright, such as stays and shrouds, providing stability to the vessel. Running rigging, on the other hand, includes the movable lines that control the raising, lowering, and adjusting of the sails, like halyards and sheets. The rigging must be carefully maintained and adjusted to ensure the ship can harness the wind effectively and navigate safely through various sea conditions.

THIS ARTICLE IS mainly for the sailboat owner or prospective owner of a boat in which the Technical Advice on the Boat Inspection Process and Why Survey Your Own Boat mast and rigging is a very important part of the structure; however, it also applies to motorboats fitted with a boat launching derrick or fishing boats on which you need to survey the trawling gear or similar equipment.

The rigging of a boat can be quite a complex structure, and there are various options for its set-up, so one of the first things to do during a survey of the mast and rigging is to pin down what system is being used and how it all hangs together. It can often look very fragile, with thin strands of wire and the seemingly impossibly thin mast supporting the stress and strain of the sails.

The first dilemma you’ll face when surveying the mast and rigging is whether to check it with the mast up or down. In some ways you want to have the mast erected to see how the whole system works and to reveal any existing weak points or wear, but it’s difficult to do a full check on rigging that is under tension since most of the wear points will be in the « nip », the point where two fittings, such as a shackle or clevis pin, link at the top or bottom of a wire. This can be a particular problem at the masthead fittings; you could examine them with binoculars or even make a trip up the mast in a bosun’s chair, but unless the rigging is slack enough so that the links in the system can be opened you won’t be able to determine if there is wear here.

Therefore, in order to examine the fittings in detail the mast needs to be down. It’s unlikely the sails will be erected during a survey, but the mainsail may be on the boom or in the mast with a mast reefing system, and a roller reefing jib could still be in place.

Mast Installation

IF THE MAST is erected, start your survey by studying it closely. Look at how the mast is fitted in the boat. On older boats it may go through the deck with the heel connecting with a mast step just above the keel. The alternative, and the system used on most modern yachts, is to have the mast step on the deck or on the coachroof, which in turn is supported by a tube or column between the coachroof and the keel or bottom framing.

This latter arrangement does away with the need to have some sort of seal around the point where the mast passes through the coachroof or deck, which has traditionally always been a source of trouble and leaks: the mast is always going to move slightly under the stresses and strains of sailing and so trying to seal this joint adequately is difficult. The traditional fix was to place mast wedges in the hole around the mast before fitting a canvas cover over them to keep the water out. A more modern system might employ a rubber boot as the seal, held in place by worm drive clips. In either case look below for signs of leaks, and if there is staining check the condition of the seal. If the seal has been removed you may see signs of movement around the joint where the mast passes through the deck/ coachroof, which will be revealed by shiny areas on an aluminium mast or wear on a wooden mast. This isn’t a serious problem (since there is always a certain amount of movement at this point) unless the wear looks considerable.

The mast step, whether it is inside or outside the boat, is a critical part of the installation as it takes the considerable downward stress of the mast and transmits it to the hull structure. There will often be a pad of some sort in the mast step, which acts as a shock absorber. On the rare occasions when the mast is removed, check the mast step and mast heel for cracks or distortion. You may find corrosion at the base of the mast, since water can lie in this area. If the mast is stepped on deck, the supporting pillar below it will normally be a rigid structure in metal, so check its base for corrosion. To be certain that it is taking the downward strain, use a straight edge to make sure it’s not bent or bowed in any way.

The Basic Equipment of a Sailboat and Their Characteristics mast is a complex structure requiring detailed examination. It is likely to be constructed from wood or aluminium, with carbon fibre composites usually only seen on racing yachts. You’ll find many fixtures and fittings attached to the mast in the way of the:

- slots for pulleys;

- antenna(e);

- and rigging wire attachments.

The complication is increased when there is in-mast reefing for the mainsail.

Hollow wooden masts are designed to reduce weight but even here most or all of the attachments and ropes will be on the outside so examination is relatively straightforward, provided you can get close access.

Check fittings for any sign of movement, such as slight abrasion in the varnish surface or the wood itself. Certain designs may encourage water to collect behind the fitting, which could start to rot, so look for discolouration of the wood. In particular, check the base of a wooden mast if it lies inside rather than on the boat. Close examination of discoloured fittings may require removal.

If you’re examining an aluminium mast, you should focus on detecting corrosion. Aluminium is extremely durable but most mast fittings will be made from stainless steel, meaning you have two dissimilar metals in the presence of sea water which could start electrolytic corrosion (seen in the creation of a grey/white powder around the meeting point).

The aluminium will suffer more than the stainless steel, although if the latter is low quality you may also see some rust coloured surface corrosion. Fittings are usually fastened to the mast with rivets, which could be a different type of metal again, so you must check all of them for the same signs of corrosion. Of course, if the mast is erected you will only be able to see the bottom part of the fitting as you look up with your binoculars.

If the mast is still up, stand back from the boat to examine the rigging. This will enable you to detect any fittings that are out of line, which could place them under additional strain. Modern rigging tends to allow for a degree of unevenness via the use of toggles and similar fittings which take up a natural alignment, so that angles are not so critical here.

However, be sure to check all fittings closely. You might see this misalignment where a shackle is attached to the chain plates and the span of the shackle opening is much wider than the width of the chain plate to which it is attached, thus allowing the shackle to cant over. A shackle that is canted in this way could be a weak point in the rigging, so all shackles should be moused with wire to prevent the shackle pin unscrewing when the rigging vibrates.

There can be a whole collection of fittings at the masthead ranging from halyard blocks to rigging attachments, electronic antenna(e) and navigation lights. These are often out of sight, out of mind so that whenever the mast is taken down, these fittings should be inspected. Binoculars should help you to check that shackles are not coming undone and wires are not unravelling but the detail can only be seen by getting up there or getting the mast down.

On a survey you should be looking for any elongation of the holes in lugs where halyard shackles are attached, or in the eyes that may also act as an attachment. Halyard attachments are often slack when the halyard is not in use, which can lead to wear in the holes or in the nip of the fitting.

The boom and its fittings need to come in for a similar check, particularly the gooseneck where the boom attaches to the mast. The double joint here should be checked for wear because it comes under considerable strain.

Carefully go over the vang attachments. If the vang is hydraulic check it for any leaks, indicated by a film of oil on the surface.

There will be more bits to check on both boats where the sail is reefed into the boom and where there is in-mast reefing.

Getting access to the moving parts on these installations can be a challenge and this may be a dismantling job that should be scheduled perhaps every time the mast is taken out.

On a purchase survey inspect everything you can see for the tell-tale signs of wear, such as shiny surfaces and a grey or brown powder.

Contact Points (« NIPS »)

AS WE SAW earlier in this chapter, the « nip » is the point at which the two surfaces of an attachment meet. You can’t see this contact point until the attachment is slackened off, which enables you to open up the contact points. While everything may look fine from the outside, if a bit of sand or grit gets into the nip and the two surfaces begin to rub together, wear will occur.