DIY Cruising Catamaran: Complete Building Guide

As an Amazon Associate, we earn from qualifying purchases. We may also earn commissions if you purchase products from other retailers after clicking on a link from our site.

A brand-new cruising catamaran can set you back a hefty amount of money. However, a DIY cruising catamaran provides a more affordable way to own your own boat. While building a large boat can be an extremely challenging and time-consuming experience, nothing beats the pleasure of bringing your own boat to life.

To build a DIY cruising catamaran, buy good design plans, determine your budget and find a working space. Next, choose your hull material, buy supplies and start building the mast beam. Build and sheathe the hull, install bulkheads, the interior, and finally, launch the catamaran boat.

In this article, you will find a complete guide to building your own catamaran. You will also find detailed information on why you may want to consider building your catamaran and approximately how much this project would cost. Finally, we will explore the advantages and disadvantages of building a catamaran from scratch.

Why You Might Want To Build Your Own Catamaran

Most people might think that purchasing a used boat to repair and fix it up would be cheaper than a DIY cruising catamaran. But while building your own catamaran could be an enormous undertaking, it also comes with many advantages over buying something used.

Other than the unique opportunity to create beautiful memories and experiences while cruising, sailing, and exploring beautiful coastlines, there are a number of benefits that come along with the DIY approach.

Knowing Your Boat

Building your own catamaran provides you with intimate knowledge of your boat. You will know every corner, including where to find every bolt, wire, bulkhead, rib, hose, and support as you installed them yourself. This knowledge will enhance your confidence while at sea since you will have entrusted your life to a boat whose history you are aware of and deeply connected to.

Pride of Ownership

The satisfaction you get from crafting something with your own hands is immense. As a result, the knowledge that you built your boat from scratch will fill you with absolute pride and an immense sense of achievement. Furthermore, as an owner-builder, you get to keep and enjoy the boat for as many years as you wish.

Substantial Cost Savings

Building your catamaran will work out cheaper than buying a new or even gently used boat. Though you will likely require some additional labor since doing some things will require an extra pair of hands, if you are particularly good at DIY, you will save a significant amount of money on labor costs as a whole.

Freedom To Create Your Own Designs

If you decide to buy a catamaran boat, it might not be easy to find one that meets your unique needs. However, instead of choosing from production boats that bear traditional and outdated designs, you can come up with an ultra-modern design or style for your catamaran. You also get to pick your layout, size, and equipment based on your taste and budget.

Great Learning Experience

Building your own boat will help you pick up numerous skills that will come in handy later when sailing your boat. As much as you might still require an expert to help you with specialized skills like carpentry or wiring, your new skills will serve you well. This will also be beneficial when it comes to your boat’s maintenance and fixing things for yourself.

What To Look For in Catamaran Boat Designs

When deciding on the type of catamaran boat to build, you may want to choose a design that’s simple and easy to build. This is because doing so will allow you to spend a shorter time building the boat.

You also need to have a set of requirements to guide you in choosing your design or what you might call an ideal cruising catamaran wish list. This is essential because, ultimately, you want to build a boat that offers outstanding qualities such as:

- Delivers good speed

- Affordable to own and operate

- Agile, strong, and easy to maintain

- Has a high resistance to capsizing

- Great for sailing and cruising

- Delivers a comfortable and easy motion underway

- Good handling ability and high performance under sail

- User-friendly embarking and disembarking

- Provides ample living and accommodation space

- Presents a reasonable resale value

It’s worth noting that, in general, catamaran boats tend to offer a fair resale value mainly because of scarcity and the high price accorded to production models. So, if you build a well-constructed catamaran, you are bound to get a return that’s much higher than the cost of materials upon resale.

It’s also good to consider whether the design you settle on is from an established designer. This is significant because documentation of the building process is just as valuable when it comes to selling the boat.

How Much Would It Cost To Build Your Own Catamaran?

The cost of building your cruising catamaran will depend heavily on the size of the boat you plan to build and the skills you bring to the table. To give you an idea of probable costs, a professionally built 40 foot (12.1 m) long cruising catamaran could go for up to $300,000.

Though building it yourself will undoubtedly be cheaper, most DIY boatbuilders tend to underestimate the expected costs. Your final costs should cover not only the cost of material and equipment but also the labor and time it would take to come up with the final product.

If you were to build a 40-foot (12.1-meter) catamaran, your cost of materials would range between 20-30% of the total cost. Therefore, for $300,000 total, the boat’s materials would range between $60,000 and $90,000. The hull tends to range between 15-35% of the total build. Again, this depends on the finish and furniture.

But before you even start working on the DIY project, you will need to figure out where to do the work. If your home has ample space, then you can opt for a backyard building. But if you live in a small apartment, then you might want to consider renting a small garage at first and then move on to a boatyard later. This is one of the significant costs involved in building your multi-haul.

What You Will Need

To get a clearer picture of how much the entire project would cost, let’s have a look at what else you will need to purchase.

- Good design plans

- Working space

- Ground tackle

- Matting and roving

- Equipment such as the engine, windows, rudders, deck fittings, mast, and rigging

In addition to the above, you also need to install plumbing and electricals. You may also want to consider going electric rather than using diesel. Not only will this drastically reduce your maintenance costs, but you get to use the regenerated power for all of your housing needs while sailing.

Some catamaran boat designs help you save costs by advocating the use of less expensive corpus materials. Most of the material goes directly into making the boat, which means there is hardly any wastage on vacuum bagging . With this method, there are few molds and temporal building forms and fewer fillers to grind off as waste. All these factors reduce the time and cost it takes to build your catamaran boat.

That said, building a boat of any kind is a huge financial undertaking. As such, you still need to have the financial ability to keep building; otherwise, your project will stall or take much longer than anticipated. Instead of enjoying yourself and making memories cruising to faraway lands, you might end up spending all your time building a seemingly never-ending boat.

To reiterate, this project is more of a labor of love, given that it involves a tremendous amount of manual work. Calculating an hourly rate on the time spent building the boat and adding this cost to that of materials may make it seem a very pricey exercise. However, it is vital to understand that your time matters, and every hour you spend working for “free” should be included.

With that in mind, you need to ensure that you are fully devoted to the boat construction project and are sure you want to do it before you begin. Stopping halfway because it seems like too much work would be incredibly costly.

How To Build a Catamaran

When it comes to building a cruising catamaran, you have 3 main options:

- You can buy an old boat and refurbish it.

- Purchase a bare hull plus deck molding for a home-boat building.

- Start from scratch and build everything, including the hull, on your own.

As mentioned above, renovating an existing boat may end up being more costly than starting from scratch. To build a catamaran boat from scratch, follow the below step-by-step guide.

Prepare the Essentials

Before you jump into such a large project, there are several important aspects to consider:

- Buy your plans from an established catamaran designer. You can also get inexpensive, easy-to-build catamaran designs online.

- Get access to a large working space or build a shed . Depending on your climate, you may need to opt for climate control to avoid an excess of moisture in humid areas.

- Decide on your choice of hull material. This could be fiberglass, aluminum, steel, wood, or ferroconcrete.

- Start working on a bill of materials estimate. Include everything that you think you need to get a better idea of the initial costs.

Build the Mast Beam

Using wood and epoxy, cut and glue together the pieces of wood that will form the mast beam. Most of the work at this stage can occur in a garage since it involves building small parts. Still, the work could take up to 4 months, so be prepared to put in long hours.

Build the Boat Hull

Now, it’s time to build the boat’s hull. A catamaran comprises two hulls which are connected with a deck. Below is a short video showing how to build a hull mold:

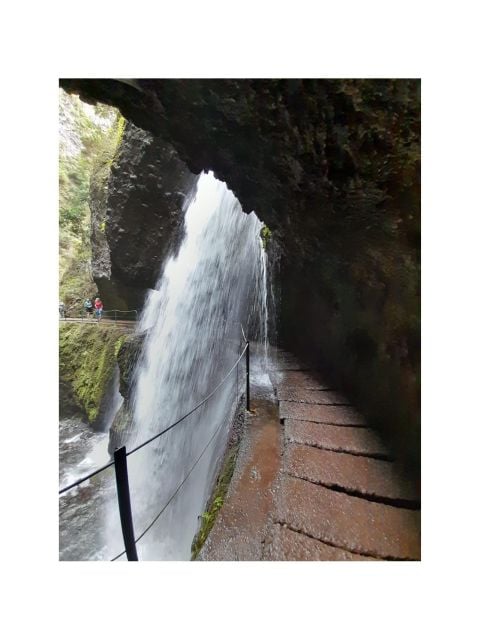

This work requires a larger facility, so you might need to move out of the garage and into a boatyard. If you don’t have access to a larger workshop, consider building a shed where you can work as you do the construction. Make sure there’s enough room to fit the boat and also allow you to work comfortably. To cover the shed, you can use opaque white tarps.

Sheathe the Hull

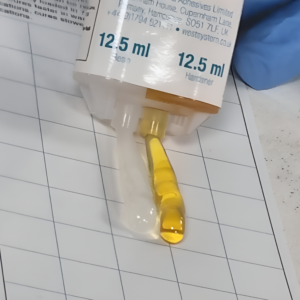

Get all the materials you require for this stage in the construction, such as lots of resin, fiberglass, and foam for use in the hull cores. You’ll also require matting and glass roving to sheath the hull .

Sheathing helps to make the hull impervious to water and other marine borers. But first, you need to prepare the hull using a rotary sander. To make it as smooth as possible, use light, sweeping strokes. This is a very dusty task so be prepared to wear a facemask and safety goggles.

Install the Bulkheads

Next is installing the plywood bulkheads . You might need to call in friends to help turn the hulls or use a crane. In this step, you will need to laminate the hull sides on the molded hull panels and bond them above the bulkheads. Ensure the bulkheads are snug and sealed in place.

Construct the Interior Structure

Over the next couple of months, the boat work will involve joining the hulls together with the beams that you had made back in the garage. Then, install the cuddy cabin, decks , and the cockpit . Soon the boat will start to take the shape of a catamaran.

Next, proceed to construct the major structural components such as stairs, hatches, mini-keels, and the interior. Then comes the work of fairing the boat, which is quite labor-intensive.

Finally, it’s time to apply primer on the catamaran boat and start the paintwork. Before painting the boat, you will need to do additional sanding to finish off the two layers of primer as well as fill all the pinholes. Since it’s a large boat, the catamaran has lots of surface area; thus, the sanding could get extremely exhausting—mentally and physically—at this point.

The painting can take a while, too. The hulls are the easiest to paint, but the topsides, non-skid, as well as masking and prepping could seem never-ending.

The final stretch involves working on the center bridge deck cabin and other final touches like installing the engines, electricals, and plumbing. This is also the time to fix the rudders, rigging, mast, windows, and deck fittings.

Launch Your Cruising Catamaran

After many months or years of hard work, your cruising catamaran is finally ready to test the waters. After lowering the boat into the water, check carefully in case there are leaks. If none, you can set up the sails and take your catamaran out for your first cruise.

Below is a short video that takes you through the entire boat-building process:

If you don’t have deep pockets, don’t despair. It’s also possible to build an inexpensive catamaran boat, as shown in this post from the coastal passage .

The Pros of Building a Catamaran

Though it will be a costly endeavor, there are so many things to look forward to should you decide to build your own catamaran:

- It can be lots of fun.

- You get to have a new boat.

- It’s an excellent hobby for DIY enthusiasts.

- The effort is rewarding.

- It offers a great learning experience.

- You get the exact kind of boat you want.

- You can alter building plans and tailor the boat to suit your specific needs.

- It might be cheaper than buying a new boat.

The Cons of Building a Catamaran

Though there are a number of positive aspects to a DIY build, it is just as important to keep in mind that it won’t always be easy:

- Maintenance costs can be quite high.

- It’s both mentally and physically exhausting.

- It might require some technical know-how.

- It can take many months or even years to complete.

- It requires a lot of commitment to finish the DIY project.

- It might be challenging as well as expensive to get insurance.

- You will spend almost all your free time building the boat.

DIY Cruising Catamaran Tips and Tricks

If you are new to boat building, it would be a good idea to build a small boat first. This would give you a good indication as to whether you’d enjoy tackling a more extensive project like building a catamaran. Again, if you are the handy type, fixing your own electronics could also save you a significant amount of money.

Here are more tips and tricks to get the most out of your DIY cruising catamaran:

- Lower your costs. Bring down your costs even further by sourcing for parts and supplies at marine surplus outlets, Craigslist, eBay, or wholesale suppliers.

- Enhance your resale value. Most home-built boats are not easy to sell since they tend to be too customized. To enhance your resale value, it’s advisable to work with a standard design from a well-established naval architect.

- Follow the design instructions. Make sure to follow the designer’s instructions regarding the type of materials and tools to use during the build to avoid making costly mistakes.

- Maintain your original budget. Avoid any additional customizations once you have started building the boat. Using good plans and sticking to them ensures that your budget doesn’t spiral out of control.

Final Thoughts

Building a catamaran is about more than saving money. It’s fun, exciting, fulfilling, and can be a great learning experience. While it might take many months of back-breaking work, comparative shopping and sourcing for materials will help you save a lot of money. Still, at the end of it all, you’ll have a beautiful catamaran boat, all ready for your first cruising adventure.

However, if you have neither the time nor the energy to build your own catamaran from scratch, refurbishing an existing hull might prove faster and easier. It also works out much cheaper than buying a new boat.

Owner of CatamaranFreedom.com. A minimalist that has lived in a caravan in Sweden, 35ft Monohull in the Bahamas, and right now in his self-built Van. He just started the next adventure, to circumnavigate the world on a Catamaran!

One thought on “ DIY Cruising Catamaran: Complete Building Guide ”

Hello, I am a French Quebecer who is original, imaginative, creative and who finds that all boats and catamarans have a huge flaw and a very big lack of logic. I would have a brand new concept…. I am sending this message to any catamaran creator – designer to make those who have the opportunity and the intelligence to want to know about my innovative idea which will finally upset the market much richer. An idea that will totally change the concept of sailing, navigation and save so much worry!! All I would ask for is a small percentage of each sale of the new product. To be able to make me produce one when I have enough!! It is certain that like that, you just want to tell me: come on Mr. Lessard give us your idea but do not take your word to help me in return! But, if you are the kind of man to have only one word and maybe have a proof of your good faith if the realization of the project would make it… I will be very happy!! Giving it to everyone wouldn’t bother me either…. all I would like is to be able to find flax fiber (too expensive carbon) to be able to try to make my catamaran myself. Because not rich! Have a nice day and looking forward to having a message!!

Leave a Reply Cancel reply

Your email address will not be published. Required fields are marked *

Save my name and email in this browser for the next time I comment.

Recent Posts

Must-Have Boat Gear for Catamaran Sailors!

Sailing is probably the most gear-intensive activity I've ever done; there are so many decisions to be made about what gear to buy now, for tomorrow, and what to definitely never buy. The gear on...

6 Best Trailerable Trimarans For Bluewater and Coastal Sailing

Having a boat costs a lot of money, even when you are not using it, marina fees, etc. And once it is in the water most sailors never go very far from their "home marina" and sailing will be somewhat...

How to Build a Catamaran Boat? (Step-by-Step Guide)

Building a catamaran boat from scratch is a rewarding and challenging endeavor.

It takes a combination of skill, dedication, and hard work to craft a seaworthy vessel.

In this step-by-step guide, you’ll learn how to design and size your catamaran, gather the necessary materials, cut and assemble the pieces, lay fiberglass and apply epoxy, make finishing touches, add hardware and paint, and rig the boat.

With the right tools, planning, and patience, you can make your dream of sailing in a catamaran a reality.

Table of Contents

Short Answer

Building a catamaran boat requires a lot of patience and skill.

The first step is to choose the right materials for the hull, such as fiberglass, wood or aluminum.

Then, you will need to build the frame of the boat, which includes the crossbeams and the main hull.

After that, you will need to install the decking, the rigging, and other components.

Finally, you will need to paint and varnish the boat, as well as install the outboard motor and other accessories.

Design & Size Considerations

When it comes to building a catamaran boat from scratch, the first step is to determine the design and size of the boat.

This should take into account the intended use of the boat, such as sailing, fishing, or leisurely cruising.

The size of the boat will depend on the number of passengers and the type of activities the boat will be used for.

For instance, a larger boat may be needed if passengers will be standing or participating in watersports.

The design of the boat is also important and should be chosen based on the intended use.

If you are looking to build a sailboat, you will need a design that is optimized for sailing.

On the other hand, if you are looking to build a fishing boat, you will need a design that is optimized for fishing.

There are a wide variety of boat designs available, so it is important to research and choose the one that best suits your needs.

In addition to the design and size, you will also need to consider the materials used for construction.

The most common materials for building a catamaran boat are wood, fiberglass, and epoxy.

Each material has its own advantages and disadvantages, so it is important to research them and determine which one is best for your project.

Finally, you will need to consider the cost of the project.

Building a catamaran boat from scratch can be a costly endeavor, so it is important to have a budget in mind before you begin.

The cost will depend on the type of materials used and the complexity of the design.

It is also important to factor in the cost of any tools that may be needed for the project.

By taking into account the design and size, materials, and cost of the project, you can be sure to build a catamaran boat that meets your needs and budget.

With the right amount of patience and attention to detail, you can build your own catamaran boat in no time.

Gathering Materials

Gathering the materials needed to build a catamaran boat from scratch can be a daunting task, but it is essential for creating a sturdy and safe vessel.

Before starting the building process, it is important to have an accurate and detailed plan for the boats design and size.

Once a plan is in place, it is time to begin sourcing the necessary materials.

The most common materials used to construct a catamaran boat are wood, fiberglass, and epoxy.

When choosing wood, it is best to select a species of timber that is strong and durable, such as mahogany, teak, or cedar.

Additionally, the wood should be clear and free of knots, splits, and other defects.

Fiberglass is a lightweight fabric that is resistant to water and provides additional strength to the boats hull.

Epoxy is a waterproof adhesive that is used to seal the boat and ensure that it is watertight.

It is important to ensure that the materials are of high quality, as this will help to ensure the boats longevity.

Additionally, it is important to purchase the necessary materials in the correct amount and size.

Too little or too much of a material can be a costly and time-consuming mistake.

Finally, it is important to keep any leftover materials for future repairs or modifications.

With the right materials gathered, the next step is to cut the wood and begin the assembly process.

Cutting & Assembly

Cutting and assembly are the most important steps when it comes to building a catamaran boat from scratch.

The first step is to decide the design and size of the boat.

This will determine the type of materials you need to gather and the amount of effort that needs to be put into the project.

After deciding on the design and size, you will need to cut the wood to fit the design.

This includes cutting the wood to the desired size, as well as cutting any additional pieces that may be needed to complete the design.

It is important to ensure that all the pieces fit together correctly and securely, as any mistakes could lead to a weak boat.

Once the wood has been cut, it is time to assemble the pieces together.

This involves attaching the pieces together with glue, screws, and nails, and ensuring that the pieces fit together securely.

It is important to be careful and patient when assembling the pieces, as any mistakes could result in a weak and unstable boat.

Once the frame is ready, it is time to lay the fiberglass, and apply the epoxy to seal the boat.

This is an important step, as it will make sure that the boat is waterproof and durable.

Finally, you can add the finishing touches, such as the hardware, paint, and rigging.

With the right amount of patience and attention to detail, you can have your own custom catamaran boat in no time.

Laying Fiberglass & Applying Epoxy

When laying the fiberglass and applying epoxy, it is important to take your time and be precise.

Fiberglass and epoxy are key components of a catamaran boat, as they provide the strength and waterproofing necessary to keep the boat afloat.

Start by laying the fiberglass over the frame of the boat.

Make sure to cut the fiberglass to size and overlap the edges for a strong seal.

Once the fiberglass is in place, mix the epoxy and begin to apply it.

It is important to apply the epoxy in a thin, even layer to ensure a proper seal.

Make sure to move the epoxy around to get it into all the nooks and crannies of the boat.

Allow the epoxy to cure and then you can begin to add the finishing touches.

Finishing Touches

Once the frame of the catamaran boat is built, it is time to add the finishing touches.

This includes adding the necessary hardware, painting, and rigging the boat.

Hardware: Before adding the hardware, it is important to ensure that the frame is stable and secure.

Add the appropriate hinges, screws, and nails to the frame.

Make sure that the screws and nails are the correct size and do not exceed the recommended load capacity of the frame.

Painting: Once the hardware is added, it is time to paint the boat.

Choose a paint that is suitable for the materials used in the construction.

Make sure that the paint is applied evenly and that the frame is completely dry before applying the next coat.

Rigging: The last step is to rig the boat.

This involves attaching the sails, running rigging, and standing rigging to the masts and booms.

Make sure that the rigging is properly tensioned and secured.

Once all of these steps are complete, your catamaran boat is ready to sail.

Hardware & Paint

The last step in building a catamaran boat is to add the hardware and paint.

This step is often the most rewarding, as it is the finishing touch.

Depending on the design of your boat, there are various types of hardware you may need.

Some of the most common items are cleats, winches, fasteners, and decking.

After selecting the required hardware, you will need to install them on the boat.

It is important to use the correct type of screws and bolts, and to secure them tightly.

Once the hardware is installed, it is time to apply the paint.

The type of paint and color you choose will depend on the design of your boat.

It is important to use a high-quality marine grade paint that is designed to handle the extreme environment of the ocean.

If you are up to the challenge, you can add some custom artwork or detail to your catamaran boat.

Adding the hardware and paint is the final step in building a catamaran boat.

With patience and attention to detail, you can create a beautiful and unique boat that will last for many years.

Be sure to take your time and enjoy the process of constructing your own boat.

Once you have finished the frame, fiberglass, and epoxy of your catamaran boat, you will need to move onto the rigging.

This is a crucial step in the construction process, as it will keep your boat safe and secure on the water.

When rigging a catamaran, there are a few key components that must be taken into account.

First, you will need to determine the type of rigging you will be using.

Typically, catamarans use a combination of standing and running rigging.

Standing rigging consists of cables and lines that stay in a fixed position to provide stability and strength to the boat, while running rigging consists of lines that are used to adjust the sail and mainsheet.

Additionally, you will need to choose the right type of rope and hardware for your rigging setup.

The rope should be strong and durable, and the hardware should be made of stainless steel and be corrosion-resistant.

Once you have chosen the type of rigging and hardware, you can start assembling the rigging lines.

This process involves carefully measuring and cutting the lines to the proper lengths, and then attaching them to the mast and boom.

Depending on the type of rigging setup, you may also need to attach the lines to the hulls and deck.

It is important to inspect the rigging lines and hardware regularly to ensure that everything is secure and in proper working order.

Rigging a catamaran boat can seem like a daunting task, but it is essential for the safety and comfort of your vessel.

With the right tools, materials, and attention to detail, you can successfully and safely rig your catamaran boat.

Final Thoughts

Building a catamaran boat is a rewarding experience that requires patience and attention to detail.

With the right plan, materials, and steps, you can build your own boat in no time.

Now that you know the basics of how to build a catamaran boat, why not grab your tools and get started on your very own project? With the right motivation and dedication, you can make your dream of owning a catamaran boat a reality.

James Frami

At the age of 15, he and four other friends from his neighborhood constructed their first boat. He has been sailing for almost 30 years and has a wealth of knowledge that he wants to share with others.

Recent Posts

When Was Banana Boat Song Released? (HISTORICAL INSIGHTS)

The "Banana Boat Song" was released in 1956 by Harry Belafonte. This calypso-style song, also known as "Day-O," became a huge hit and remains popular to this day for its catchy tune and upbeat...

How to Make Banana Boat Smoothie King? (DELICIOUS RECIPE REVEALED)

To make a Banana Boat Smoothie King smoothie at home, start by gathering the ingredients: a ripe banana, peanut butter, chocolate protein powder, almond milk, and ice. Blend the banana, a scoop of...

|

| | | | |

|

HOME / INDEX PAGE Your source for the latest news on yachts, boats and more. Read through our articles to find out how to compare boats and find the right fit for you! Power Catamarans: A Complete GuideDec 06, 2023 less than a min  Power Catamarans, often termed as the epitome of modern maritime engineering, are gaining popularity for all the right reasons. Their distinct design, enhanced stability, and cruising efficiency set them apart from traditional monohull boats and even their sail-driven counterparts. This guide dives into the world of Power Catamarans, shedding light on their advantages and how they compare to other vessels like monohulls and trimarans. Historical Prelude:The concept of catamarans traces its roots back to ancient maritime cultures. However, the power catamaran is a relatively modern innovation that marries the traditional twin-hull design with powerful engines, offering a unique blend of speed, stability, and space. Distinguishing Design:Power Catamarans are characterized by their twin hulls, which significantly reduce the drag, thus enhancing speed and fuel efficiency. Unlike monohulls, they have a broader beam, which contributes to increased stability and more living space. The absence of a ballast for stability further lightens the vessel, contributing to its speed and fuel economy Speed and Handling:One of the significant advantages of power catamarans is their speed and handling. The twin hulls allow for a smoother glide over the water, making them particularly favorable for watersports enthusiasts. Their handling in rough waters is superior to monohulls, thanks to the inherent stability provided by the dual-hull design. The stability of power catamarans is unparalleled, especially when compared to monohulls. The wide beam and twin hulls provide a stable platform, reducing the rocking and rolling common in monohulls. This stability is not only comforting in rough seas but also crucial when docking or anchoring. Comfort and Space:The spacious design of power catamarans offers homelike livability, with ample room for cabins, lounges, and even onboard amenities like grills and bars. The wide beam also allows for large deck spaces, ideal for sunbathing or enjoying the scenic ocean vistas. Economy and Redundancy:Power catamarans are economical, with fuel efficiency being one of their selling points. The redundancy built into their design, with separate engines for each hull, provides an added layer of safety, ensuring that the vessel can return to shore even if one engine fails. Regular Upkeep and Care:Power catamarans, given their unique design and structure, come with their own set of maintenance requirements. Like all boats, routine checks and upkeep are essential to ensure smooth sailing. The twin hull design means double the underwater gear – from propellers to rudders, which necessitates regular inspections for any signs of wear, tear, or fouling. Antifouling:Given that power catamarans have a larger surface area underwater due to their twin hulls, they may be more susceptible to marine growth. Regular antifouling treatments can help in keeping the hulls clean, ensuring optimal performance and fuel efficiency. Engine Maintenance:One distinct advantage of power catamarans is their dual-engine setup, but this also means double the engine maintenance. Regular oil changes, cooling system checks, and filter replacements are crucial. It's beneficial to synchronize maintenance schedules for both engines to ensure consistent performance. The lifespan of a power catamaran largely depends on its build quality, materials used, and how well it's maintained. With proper care, a power catamaran can last for several decades. The engine's maintenance significantly impacts the catamaran's lifespan, with gasoline engines requiring maintenance at 1,200 to 1,800 hours and diesel engines at around 5,000 hours. The construction materials play a crucial role; for instance, fiberglass catamarans, when well-maintained, can last for many decades, while aluminum cats might change ownership after 10-15 years but can last a lifetime with proper care. World-Renowned Builders:The power catamaran sector boasts several reputable manufacturers such as Lagoon, Leopard Catamarans, Fountaine Pajot, and other notable names like Seawind Catamarans. Lagoon, a revered name under the Beneteau Group umbrella, has carved its niche in crafting luxurious, spacious catamarans. A prime example is the Lagoon 630 Motor Yacht, embodying opulence with its nearly 250 sq. ft. aft deck and 900 sq. ft. interior, comfortably housing up to 12 guests. Known for its superyacht styling, it boasts superior fuel efficiency and a commendable average velocity-made-good of 9 knots. Leopard Catamarans:Emerging from the reputable Robertson and Caine shipyard in South Africa, Leopard Catamarans is synonymous with innovation and efficiency. The Leopard 53 Powercat is a testament to this legacy, showcasing excellent seakeeping abilities, offering 3 or 4 cabin configurations, and achieving a top speed of 25 knots. Fountaine Pajot:A trailblazer since 1976, Fountaine Pajot constantly redefines catamaran design. The Fountaine Pajot MY6 is a shining example, encapsulating the brand's visionary ethos. Stretching 15 meters, the MY6, equipped with dual engines of up to 2 x 353 Kw and 2 x 480 hp, promises dynamic sailing. Crafted meticulously by Pier Angelo Andreani, the interior mirrors a 20-meter monohull's spaciousness, reflecting modern aesthetics and comfort that stand as a benchmark in the Motor Yacht world. These manufacturers continue to innovate, offering a blend of luxury, performance, and efficiency in their power catamaran models, making them a popular choice among maritime enthusiasts. Comparing with Monohulls and Trimarans:While monohulls are traditional and often cheaper, they lack the stability and space offered by power catamarans. On the other hand, trimarans, with three hulls, provide even more stability but at the cost of additional drag and less interior space. TheBoatDB - Your Gateway to Maritime Exploration:If you’re looking to delve deeper into the world of power catamarans and other vessels, TheBoatDB offers a comprehensive boat database. Explore various catamaran models, compare them with monohulls, trimarans, and other types of boats, and make an informed decision on your next maritime adventure. In summary, power catamarans encapsulate a modern engineering marvel in the maritime domain. Their blend of speed, stability, comfort, and economy makes them an attractive option for a broad spectrum of boaters. Whether you are a long-distance cruiser, a water sport enthusiast, or someone who cherishes the tranquility of the sea, a power catamaran could be the vessel that transforms your maritime adventures into unforgettable experiences. You might like these too Sailboat or Motorboat – Learn the pros and consAug 24, 2022  Types of Catamaran Boats: Sailing, Power, and Luxury CatamaransFeb 10, 2023  Which is better a wooden boat or fiberglass boat What are the main types of sail rigs for sailboats Which is the Best Economical CatamaranOct 04, 2021  What is a Chine on a BoatOct 01, 2021 Time For a Catamaran AdventureIsn't Time For Yours? Building Your Own CatamaranBuilding your own catamaran is another option to getting into your own boat. In this page we will go over the advantages, considerations, and a detailed history and journal of our boat-building adventure with Light Wave . We hope this will give you a clear picture of what lies ahead if you go this route, including:

Because of the huge dollars needed to buy a new or even a used catamaran, we would never have gotten a catamaran if we hadn’t built it ourselves. Let’s start by saying that building any type of larger boat, especially a catamaran, can be one of the most intellectually and physically challenging things you will ever do. It has been said that building a large boat is the closest a man can come to giving birth to a baby. In other words there is going to some discomfort and pain along the way; you will question yourself on whether this was such a good idea; it’s very difficult to reverse the decision; and though friends will support you, you will be on your own most of the time with your significant other if he/she is game. Know your boat You will intimately know every part of your boat. You will know where every wire, hose, bolt, bulkhead, rib, and support is because you installed them! Pride of ownership We have often thought what it would be like to just buy a boat from a manufacturer, and know that while owners who have spent a lot of cash (or future life to pay off the lien) their often possessive and competing-with-the Joneses could not begin to compare to our quiet glow of happiness and akinship we feel with Light Wave . Our boat is like part of the family. So much time was spent on her that we have a major emotional investment. Every time we see our vessel – from a distance at anchor or approaching her in our marina, we say, “What a pretty boat! I can’t believe we built it!” Then that sense of accomplishment settles back in and we feel we have indeed earned the privilege of all of the beautiful experiences we have had sailing, cruising, exploring the beautiful BC Coast and much further a field (or should we say “an ocean”?). You will be able to pay for the materials as you go and “donate” your time to the cause. Get a newer design Many of the production boats that are out there are designs of many years ago because the manufactures have to recoup their capital investment on the mold and production setup. When you build your own you have much newer designs to draw from. Details on Our Boat Building Adventure We had sailed our first boat Wave Dancer for five years and had many adventures on the British Columbia coast. In May 1996, I had just returned from a little one-week solo trip in the Gulf Islands of BC when I bought the book, The Cruising Multihull by Chris White (Future link to book review on our web site). This is the book that got me going (Carllie was not yet convinced). I must have read it a half dozen times over the next 6 months, each time becoming more convinced that this was the way to go for our next boat. It was really still pre-internet web site days so I wrote to all the designers that were listed in the back of the book. Over the next several weeks packages of information started appearing in the mailbox (there is just something about getting packages in the mail – I guess it’s the anticipation). I would pour over these preliminary printed pages with pictures and accommodation layouts. Next, I put a few dollars down to buy the information packages and study plans from the top prospects. I waited patiently for the study plans. It was like the night before Christmas when I was kid. Oooh the wait! Finally they came, and again I carefully scrutinized the next level of detail. Things were getting a little more serious. The top contenders were:

Click here to read my comments and reviews on their catamaran designs as well as those of Jeff Schionning. I remember initially drooling over the Atlantic 42 by Chris White, still one of my favorite designs. It seemed to be so seaworthy (by the way if I run into about $800,000 USD any time soon, I am going to buy an Atlantic 55). The most important piece of advice that came out of the material was from Richard Woods: “Build the smallest boat you‘d be happy with it.” Axiom #1: The hours to build a catamaran is in almost in direct proportion to its weight. Which brings us to Axiom #2: Axiom #2: It takes about 1 hour to create 1 pound of finished boat. In our case we spent 3,500 hours ( click here for full details on the construction hours ) to build a 4,000 lb. boat (just a little less than 0.9 hours per pound). If a boat’s empty weight is 8,000 lbs., it will probably take about 6,000 hours to build. When you think about it, you can only mix and handle so much material per hour. More boat weight, more material, more hours. Sure there are some economies of scale on a bigger boat, but usually the systems become more complex and these take longer to install. This decision process took 8 months and I figured we’d launch in 6 months. It was now January of 1997. Little did we know it would be 26 months and 3,500 hours between the two of us until we launched on June 5, 1999. We ordered the full plans and we were off and running. We were ready to build, but where would we start the process? First of all, we live in a tiny 480 sq. ft. apartment in Vancouver. Back-yard building wasn’t exactly an option so I found a small garage nearby that we rented for 5 months. After about 4 months in the garage, I had made all the small parts and it was time to build the hulls. This meant that we had to go larger facilities. We found space at Shelter Island Marina and Boatyard in Richmond. This is the biggest boat yard in the Vancouver area with dozens of commercial and private projects, big and small, under way. We were out of money by then, so we sold our first boat so we could buy resin and fiberglass. It was a traumatic time as we said goodbye to our beloved Wave Dancer . We were now committed. We than had all the foam for the hull cores, barrels of resin, and huge rolls of matting and roving needed for the fiberglass skins delivered to our “domed stadium”. We kicked ourselves many times that we didn’t take a picture of this raw material stacked in one corner of the empty shed, so we could later show “before” and “after” photos. It was time to build the hulls. Over the next several months we proceed to join the hulls with the beams I had built in the garage, and then to install the cuddy cabin, cockpit, and decks. By the spring of 1998, it was staring to look like a catamaran. Through the spring and summer of 1998, we continued with the major structural components: mini-keels, hatches, stairs, and interior. Then we went on to the very laborious work of fairing the boat before painting. Don’t under estimate that job! By October 1998 we were ready to prime the boat and start painting. I really thought this would go quickly. I forgot that I would have to do two more complete sandings to sand off and finish the two layers of primer application. In addition we had to fill countless pinholes – a laborious process somewhat like hiking up a mountain – each time you get to what you think is the top, you see another summit! The boat seemed to get bigger and bigger. Believe me, there is a lot of surface area on a catamaran. I clearly remember that last sanding: I had reached the end of my physical and mental endurance – I was exhausted. I was ready to move on to the next phase – any phase but more sanding! We now started spray-painting the hulls bright yellow. It was around this time we decided on our boat name of Light Wave . The painting took over a month: the hulls being the easy part, it was the topsides, the nonskid, and all the masking and prep that seemed to take forever. Happily, the worst of the dust was gone. By March 1999 we were in the home stretch. The center bridge deck cabin was completed so we took a week off from our paid jobs and lived on the boat in the shed so we could work all day and not waste time commuting. March, April and May were frantic months as we finished all the final touches: engine installation, rudders, windows, deck fittings, electrical, plumbing, mast, and rigging. See our outfitting page (for more details on what we picked and why, and things we would do differently now. Initially, our electronic systems were relatively basic but included GPS and autopilot see the following link for all our electronic outfitting choices and reasoning for more details. It was May 22, 1999 and we decided that Saturday, June 5th would be “Launch Day” so we could send invitations to all of our friends. On the Friday night before Launch Day, we still had a number of final things to do, many of them outside. Unfortunately it was pouring rain. We were tired and very wet but the boat had to go into the water next day so we persevered on till everything was ready. The moment of truth came as Light Wave was lowered into the water. While still in the slings of the Travelift, I jumped aboard to check for leaks. Of course there weren’t any! More food and laughs and tours of the boat for all attending. It was a great day. Emotionally drained that night, we slept in Light Wave in the water for the first time. It was another week before we actually went out for our first trip as we had to sell the shed, setup sails, and install some final deck hardware. To sum it up, building a catamaran was a great experience. We learned a lot. Carllie and I grew closer together through it all. We had a great time doing it. We had a beautiful catamaran to show for it. Now it was time for a catamaran adventure !

Service Locator

The Planing Power Catamaran: A Different Kind Of CatAdvertisement Planing powercats deliver the high speeds dayboaters and weekend anglers crave — but without so much pounding in choppy seas. The air cushion created between the two hulls dramatically reduces wave impact at running speeds. (Photo: World Cat) Powercats are different beasts than sailing cats, and the powercats you're most likely to see on your local waters are those in the 20- to 40-foot range (like my 22-foot Glacier Bay). Unlike the big cruising powercats, which are more like cat trawlers with top ends maybe a little over 20 mph, smaller cats have planing hulls that perform much like today's modern powerboats. Depending on the engine package, there are a few cats that top out in the lower 30s, lots in the lower 40s, some in the 50s, and a few that break 70 or even 80 mph. While a similar length monohull may have a 40-mph cruising speed in a 2-foot chop, the monohull captain will pull back the throttles and cruise at 30 to avoid being beaten up. The cat guy, on the other hand, may be able to keep on doing 40 thanks to the smoother ride. But having two hulls underfoot does create some interesting similarities in how these different types of boats react to input from the helm. So you'll see a few of the tips here mirror those used for sailing or cruising catamarans. Whatever type of cat you may be captaining, remember the following:

Why Two Hulls?Like all boats, catamarans come with distinct advantages (smooth ride, draft), and areas of compromise (docking, turning). Regardless of design aesthetics, the first question is usually: Why two hulls? Mike Myers, vice president of product development for World Cat explains: "Catamaran hulls experience little to no drag or resistance to get on plane, resulting in greater fuel economy. They have a steady rise in speed and fuel burn with little to no spikes in fuel consumption."Planing powercats have a unique trait — which many cat lovers consider the top advantage over monohulls — the impact-absorbing cushion of air created by a compression tunnel between hulls. And when it comes to beam, catamarans' parallel hulls create reliable stability, which helps to avoid heeling and capsizing, and greatly reduces the vessel roll at rest and at trolling speeds. "Many boats are primarily designed around comfort for the captain. This usually means anyone at the front or sides of the boat takes most of the jostling,"Myers says. "The catamaran-style hull delivers ride comfort, smoothness, load distribution, and stability."That stability draws anglers to powercats of typically 20 to 40 feet; and cruisers to sailing cats 40 to 60 feet and beyond. — Rich Armstrong Taming The CatWhen it comes to handling powercats in open waters, the most important thing to remember is that all boats are different. Just as you wouldn't lump the handling characteristics of all monohulls together, the same goes for powercats. But many have a few common traits to consider.

Photo: World Cat

Related ArticlesThe truth about ceramic coatings for boats. Our editor investigates the marketing claims of consumer-grade ceramic coatings. Fine-Tune Your Side Scan FishfinderTake your side-scanning fishfinder off auto mode, and you’ll be spotting your prey from afar in no time DIY Boat Foam DeckingClosed-cell foam flooring helps make boating more comfortable. Here’s how to install it on your vessel Click to explore related articles Lenny RudowNew Boats, Fishing & Electronics Editor, BoatUS Magazine Top tech writer and accomplished sports fisherman, BoatUS Magazine Contributing Editor Lenny Rudow has written seven practical boating books, won 30 awards from Boating Writers International — many for his marine electronics articles – and two for excellence from the Outdoor Writers Association of America. He judges the NMMA Innovation Awards, and is Angler in Chief at FishTalk, his own Chesapeake-based publication. A great teacher and inspirational writer, Lenny hosts many of BoatUS Magazine’s very-popular how-to videos, which can be found on the BoatUS YouTube channel, or at BoatUS.com BoatUS Magazine Is A Benefit Of BoatUS MembershipMembership Benefits Include: Subscription to the print version of BoatUS Magazine 4% back on purchases from West Marine stores or online at WestMarine.com Discounts on fuel, transient slips, repairs and more at over 1,200 businesses Deals on cruises, charters, car rentals, hotel stays and more… All for only $25/year! We use cookies to enhance your visit to our website and to improve your experience. By continuing to use our website, you’re agreeing to our cookie policy. Projects: Constructing a 40ft catamaran with WEST SYSTEM epoxyWork doesn’t necessarily slow down after retirement, as engineer Martin Ellison proved when he left his teaching post at the age of 59 and set about building his first boat. What started as some prompting from his wife to find a meaningful project evolved into the idea of building a 40ft catamaran. Martin tells epoxycraft how it all came about. I have always loved being on or near the water and wanted to have a boat of my own. As someone who has renovated a few houses in the past, I wasn’t daunted by the idea of building a wooden boat from a set of plans, although I’m not sure it was the scale of project my wife had in mind!  I chose to build a catamaran because I wanted the space and stability; preferring a power cat, I searched online for some designs and went for the Skoota 36 ( Woods Designs ). This is a relatively simple timber and plywood design sheathed in fibreglass, although I have slightly modified the design to increase the length to 40ft so that I could enlarge the accommodation space in the hulls. When I began in earnest in September 2014 I didn’t even have a boat shed, so that was the first project. It was ready for action by March 2015 and I have been steadily working on the boat for the past nine months. I’ve used WEST SYSTEM epoxy all over… and found its strength and versatility to be ideal. For the build I’ve used WEST SYSTEM® epoxy all over – jointing, filleting, waterproofing and sheathing and have found its strength and versatility to be ideal for this project.  I’ve mainly used WEST SYSTEM 105 Epoxy Resin® with WEST SYSTEM 205 Fast Hardener® . In addition, I’ve combined the epoxy mix with WEST SYSTEM 403 Microfibres and WEST SYSTEM 409 Microsphere Blend® to ensure all the gaps have been thoroughly filled. When it came to sheathing, I used 300g and 600g Episize™ Biaxial Fabric and 300g woven WEST SYSTEM 787 Aramid Fabric® to provide extra protection below the waterline.  The boat build so far has taken just over 1100 hours. It’s a big boat and there’s a lot of work – mainly woodwork – involved in completing each stage. I’m enjoying it though, it’s very rewarding and most of the build has gone pretty smoothly. As luck would have it there is another Skoota 36 being built in Canada which is about one year ahead of me and the owner has very kindly shared his build photos, which has been a great help. People say it looks very difficult but in practice it isn’t – it’s simply a case of following the plans and having the confidence to get on with it. There’s still a bit of a way to go but I’m really looking forward to turning over so we can finalise the internal layout and then getting her in the water and cruising in her. Our thanks to Martin Ellison for sharing his story. We wish him well and will be following him closely as he completes his build. If you would like more information about this project you can follow the build on https://my-new-cat.weebly.com Back to projects  G/flex® 650 vs. 655: Choosing the Right Epoxy Adhesive Swiss Couple’s Boat Restoration Rescue? What Can You Do With a WEST SYSTEM® Epoxy A Pack?[email protected] Category: Our Catamaran Build KitsRecommended equipment.  Quality suppliers & manufacturersThe schionning team have a lot of contact with equipment suppliers and manufacturers, and hear feedback on certain brands or systems from our many customers. there are many schionnings cruising the world and testing products longevity and the customer service offered by the manufacturer., on this page we will list products and companies that we know to provide above average quality and service. it is always growing, and if your company provides equipment used on our designs and you would like to be included - please contact us., engines & drive systems.  Visit: https://oceanvolt.com Batteries, Power Management LITHIUM POWER (VIC)Back in 2013 I knew that my boat batteries were reaching the end of their lives, I had been researching LiFePO4 cells for a few years and decided that I should install them. Unfortunatly I was unable to find a local supplier. So Lithium Power was established. Technical InformationThe technical information page is a collection of documents (mostly in pdf format) on the materials and systems used in schionning catamarans. including data sheets, engineering information, strength comparisons of each core material and informative articles from jeff outling the design of certain system such as engine choices and main sheet systems., detailed engineering data for your research, we understand that getting your head around the process of building your own boat, or having one built, can take a little while. to gain a greater understanding of the materials used in our designs, the below data sheets have been supplied by atl composites, and contain all of the technical data you could need regarding the composites we use. in addition are articles or documents written by jeff about certain systems used on our designs and why., all technical information and data sheets on west system/duflex/durakore provided courtesy of atl composites. for more information please see the atl composites website here., documents library. Information Sheet – CE CERTIFICATION PROCESS

Kit Materials ContentsKit materials' contents, so if you order a schionning kit, what exactly is going to arrive see an overview of the materials you will receive, and what each is used for during the build process. fibreglass cloth or tapes microspheres, microballoons or microfibers take a closer look and you can answer these questions., our schionning kits are a no nonsense, common-sense approach to building a boat. we offer great service, fast delivery and access to anything you could need for your boat straight from the supplier to your door. our construction plans and kits are sold with 100% professional boatbuilder support via phone and email, any time you're unsure or just need a second opinion, we're here..  Our kits contain all of your basic materials to build your boat to a faired shell stage, ready for painting and fit-out. We have sail-away costing estimates available for all of our standard designs, and this will give you an accurate idea of the overall cost of your project. This costing varies depending on your level of finish, as you can imagine different options vary greatly in price.Below is a quick glance at what your Schionning Kit will include and what each item is primarily used for, we hope this is helpful and if you should require more detailed information please don’t hesitate to contact our office. What do I actually receive? DUFLEX PRE-LAMINATED PANELSDuFlex pre-laminated panels are the main and most important material used in our kits, predominantly in the flat panel designs, however they are used in Strip-planked designs also, though to a lesser extent. These panels are 2400mm x 1200mm and are CNC routed to speed up build time on our Wildernes X Series, as well as some of our power designs. For internal furniture, a paper honeycomb core is used instead of the end-grain balsa wood core that is used for main structural areas. The use of this is purely to save weight in the shell and therefore produce a faster, more responsive catamaran.  KINETIX LAMINATING RESIN & HARDENER WEST SYSTEM EPOXY RESINS FIBREGLASS TAPES (DOUBLE BIAS) CARBON FIBRE CLOTH FIBREGLASS CLOTHThe kit process, building your own boat can be a daunting prospect, however to demonstrate each step in the kit assembly process, we've created this guide for you to study. as you can see our kits are the ultimate in building efficiency and have been streamlined over 30+ years to ensure that you're on the water faster and with less effort., how does it all go together.  The first step to building your dream catamaran begins with a strongback – this is a square frame used to position the temporary frames that will be used to form the hull shape. This frame will be set up and must be square and accurate, a string or laser level can be used to achieve this.  The forebeam is now installed along with the striker attachment fitting, as shown above. The bridgedeck is installed shortly after and taped onto the bulkheads with webs installed, this now completes what is a quite stiff and strong platform to work on.  Now that the bridgedeck is in place, the forward webs and dash will be fitted. At this stage, all furniture and internal work begins, with the main panels left off for ease of access when working.  Material ChoicesSchionning material choices, solutions that work best for catamarans & why, our designs are based on cored composite construction techniques using west system epoxy resin and knitted fabrics. but given the range of today's composite technologies, which solution works best for catamarans and why written by jeff schionning, selecting the correct materials, resin choices.  It also fully protects the boat against water absorption and it can not develop the dreaded Osmosis. We choose ATL Composite’s resin systems for their superior quality, reliability and value for money. Having worked closely with the ATL Composites team and their products for many years, we know we can stand by their material solutions, and rely on great service should something unexpected happen.  This may not seem important but when working with a material for an extended period of time, the small things make all the difference. CORES Which One to Use?

BALSA END GRAIN (150 kg/cubic metre)Balsa has very good values and we can produce a shell using a very light laminate. It will be very stiff and very resilient to fatigue. It has exceptional qualities including very high compression strength, extremely good sheer capabilities and fantastic sheer stiffness. Compressive strength is the resistance to collapsing when pressure is applied perpendicular to the surface as when pushing directly onto the material with the point of your finger. Balsa is far stronger than Foam (80kg/cubic metre) in compression. Balsa is also very strong in shear. This is when the core sample is held flat between your hands, one hand slid one way and the other slid the opposite way, when the core tears through the middle the core has failed in sheer. The amount of stretch you feel before the core shears is shear stiffness. To compensate for sheer weakness the core is made thicker. So 13mm Balsa may be equal in sheer to 19mm Foam. (80 to 200 kg/m³) There are many boats sailing that are built from foam as it’s mechanical properties are good for boat building.

The end result using foam core amounts to a very similar total boat weight. Professional builders can achieve a good result but usually use vacuum bagging and very good molds to achieve this. Secondary IssuesBalsa can absorb water. It needs extreme neglect to rot (very unusual). Water soaks along the end grain quickly. It travels very slowly across the grain. We use balsa under the waterline especially because of it’s high compression strength for beaching etc. any core type must be sealed. Damage to all cores results in the same sort of repair. Notice a damp spot remaining when drying out to anti-foul… simply grind back the surface glass exposing the core, dry it out and re-glass – it’s that easy. Timber cores are cheaper than Foam in most cases. A light, high tech cat returns a far better (often 2 – 3 times) re-sale than lower tech materials. Often saving $10,000 on materials initially, loses $200,000 on re-sale – a serious reality. Our boats can be built using Balsa, Foam or Western Red Cedar. Combine strength, stiffness, lightness and cost, with ease of use – it just makes good sense! Did You Know That We Offer Contract to Closing Services? Click Here to Find Out More. Need Marine Financing? Apply Here With Our Partner, First Approval Source

Catamaran Design Formulas

Part 2: W ith permission from Terho Halme – Naval ArchitectWhile Part 1 showcased design comments from Richard Woods , this second webpage on catamaran design is from a paper on “How to dimension a sailing catamaran”, written by the Finnish boat designer, Terho Halme. I found his paper easy to follow and all the Catamaran hull design equations were in one place. Terho was kind enough to grant permission to reproduce his work here. Below are basic equations and parameters of catamaran design, courtesy of Terho Halme. There are also a few references from ISO boat standards. The first step of catamaran design is to decide the length of the boat and her purpose. Then we’ll try to optimize other dimensions, to give her decent performance. All dimensions on this page are metric, linear dimensions are in meters (m), areas are in square meters (m2), displacement volumes in cubic meters (m3), masses (displacement, weight) are in kilograms (kg), forces in Newton’s (N), powers in kilowatts (kW) and speeds in knots. Please see our catamarans for sale by owner page if you are looking for great deals on affordable catamarans sold directly by their owners. Length, Draft and BeamThere are two major dimensions of a boat hull: The length of the hull L H and length of waterline L WL . The following consist of arbitrary values to illustrate a calculated example. L H = 12.20 L WL = 12.00  After deciding how big a boat we want we next enter the length/beam ratio of each hull, L BR . Heavy boats have low value and light racers high value. L BR below “8” leads to increased wave making and this should be avoided. Lower values increase loading capacity. Normal L BR for a cruiser is somewhere between 9 and 12. L BR has a definitive effect on boat displacement estimate.

Owner of a Catalac 8M and Catamaransite webmaster. 10 replies on “Catamaran Design Formulas”Im working though these formuals to help in the conversion of a cat from diesel to electric. Range, Speed, effect of extra weight on the boat….. Im having a bit of trouble with the B_TR. First off what is it? You don’t call it out as to what it is anywhere that i could find. Second its listed as B TR = B WL / T c but then directly after that you have T c = B WL / B TR. these two equasion are circular…. Yes, I noted the same thing. I guess that TR means resistance. I am new here and very intetested to continue the discussion! I believe that TR had to be looked at as in Btr (small letter = underscore). B = beam, t= draft and r (I believe) = ratio! As in Lbr, here it is Btr = Beam to draft ratio! This goes along with the further elaboration on the subject! Let me know if I am wrong! Regards PETER I posted the author’s contact info. You have to contact him as he’s not going to answer here. – Rick Thank you these formulas as I am planning a catamaran hull/ house boat. The planned length will be about thirty six ft. In length. This will help me in this new venture. You have to ask the author. His link was above. https://www.facebook.com/terho.halme I understood everything, accept nothing makes sense from Cm=Am/Tc*Bwl. Almost all equations from here on after is basically the answer to the dividend being divided into itself, which gives a constant answer of “1”. What am I missing? I contacted the original author on Facebook, but due to Facebook regulations, he’s bound never to receive it. Hi Brian, B WL is the maximum hull breadth at the waterline and Tc is the maximum draft. The equation B TW = B WL/Tc can be rearranged by multiplying both sides of the equation by Tc: B TW * Tc = Tc * B WL / Tc On the right hand side the Tc on the top is divided by the Tc on the bottom so the equal 1 and can both be crossed out. Then divide both sides by B TW: Cross out that B TW when it is on the top and the bottom and you get the new equation: Tc = B WL/ B TW Thank you all for this very useful article Parfait j aimerais participer à une formation en ligne (perfect I would like to participate in an online training) Leave a Reply Cancel replyYour email address will not be published. Required fields are marked * Save my name, email, and website in this browser for the next time I comment.

Circumnavigating in a Power Catamaran – A Leopard 53 PC Owner Story[july 19, 2024].  When boating folks talk about circumnavigating the globe, they generally think about doing so under sail. Sailboats use wind for fuel and handle well in offshore conditions, right? Many who consider circling the globe on a power assume that a trawler or other slow-displacement boat is the way to go. How else can you do it without massive fuel tanks and a slow, efficient hull design? Well, you know what happens when we assume. Don Richards and his wife, Anja, are currently making a circumnavigation in their Leopard 53 Powercat. We caught up with them in Tahiti as they prepared for the next leg of their journey. -4.png?width=1080&height=540&name=Untitled%20design%20(12)-4.png) Coming from a monohullThis is Don and Anja’s second circumnavigation. That first experience, made in a monohull sailboat, shaped their plans for their current adventure, including the decision to make the odyssey in a Powercat. “Mainly, I got tired of sailing and grinding winches,” Don told us. “I’m nearly seventy. I’m done raising the mainsail.” He also noted that while sailors spend a great deal of time under sail on longer transits, once they arrive at a destination, most of their shorter trips—between islands, for example—are under power. So why not just motor all the time? “The biggest difference once you arrive at a destination,” he adds, “is the Powercat is a floating apartment compared to a monohull. It’s a lot more comfortable.” -3.png?width=1080&height=540&name=Untitled%20design%20(17)-3.png) Powercat passage makingThe Richards picked up their new Powercat 53 at the Leopard facility in Cape Town, South Africa. They spent a lot of time there making measured runs, logging fuel consumption and building realistic performance curves for passage making. Their work paid off, and their load and consumption tables were accurate throughout their Atlantic and Pacific crossings. The couple travels at a leisurely pace to maximize range. Don and Anja do most of their crossings and passages at seven knots, which gives them a range of close to 1,700 miles. At nine knots, by comparison, their range drops to 1,000. They’ve installed reserve tanks with an extra 100 gallons (400 liters) of fuel but never needed those reserves for cruising. The Richards filled two 290-gallon (1,100L) fuel bladders carried on deck for a few very long passages. Of course, the Powercat’s ability to cruise at 18 knots comes in handy when rough weather looms, the customs office is closing, or nightfall approaches. “A big difference between powering and sailing is knowing when you’ll get there,” Don says. Since you’re not subject to the vagaries of light air and wind direction, planning is much more accurate and predictable under power. -3.png?width=1080&height=540&name=Untitled%20design%20(15)-3.png) The passage westThe Richards are Australian and may eventually bring their Powercat back to Australia. Like most cruisers, however, they write their plans in wet sand at low tide, so they’re still determining when or if they’ll finally get it Down Under. Of course, the shortest straight-line distance from Cape Town to Australia is east, across the Indian Ocean, but that is not a recommended route. Prevailing wind patterns, currents, and weather make a passage east from Cape Town unpleasant and possibly dangerous. “We spoke to a lot of experienced delivery captains and skippers. And they all said clearly, do not go east,” says Don. Instead, they headed north and west across the South Atlantic. They envisioned heading up through the Caribbean to the U.S. East Coast and over to Europe to cruise the Mediterranean. But the realities of hurricane season and insurance needs kept them south, and they found themselves headed towards Panama and passing through the canal. On their last circumnavigation, Howard and Anja didn’t make it to Central America or Mexico, so they headed north after coming through the Panama Canal to see it this time. Eventually, they set out from Puerto Vallarta, Mexico for French Polynesia, where they made landfall after a 2,710-mile leg to Hiva Oa. Almost all of that was powering straight on the rhumb line. -3.png?width=1080&height=540&name=Untitled%20design%20(18)-3.png) Cruising differencesThe most notable differences when cruising with a Powercat instead of a monohull are the onboard space and comfort. There’s no comparison with a monohull for the comfortable living space on a stable platform with a full-sized galley. The other is redundancy. You’ve got two engines in two hulls, so there’s always a second engine if one has trouble. The Powercat also changes where and how the Richards anchor since they can tuck in closer to shore inside the keelboats. Anchoring in shallow water with more protection from shore is almost always better, and moving short distances between anchorages is quick and comfortable. Hauling the Powercat out of the water takes a little more planning. Like a sailing catamaran, you have a lot more beam and need a travel lift to handle the size. But the bridge deck and cross beams are stout, and Robertson and Caine, builders of the Leopard Powercat, were always available with helpful instructions for where to best place the straps for the safest lift.  Where to next?The Richards’ current plan is to head to Samoa and likely spend the cyclone season in New Zealand. Next year, they may visit Vanuatu, New Caledonia, and stop at Norfolk Island. Like all their plans, these may change with the conditions. “We’d also love to head over the top of Australia back to southeast Asia,” Don says. “Maybe the Solomons, Papua New Guinea. Australia’s always an option, too. Who knows?” When asked one thing potential Powercat cruisers should know, Don’s answer was unequivocal: “You need to know that you can get almost anywhere with the standard tanks. Sure, you’ve got to slow it down. But don’t think you’ll be limited by fuel if you don’t want to be.” No limits. Sounds like the perfect mantra for world cruisers. Related articles Sailing the BVI on a Leopard 50: A Vacation ItineraryAugust 7, 2024.  The Leopard Family: How to Find Your CommunityJuly 26, 2024.  Ask a Leopard Owner: Dave + Beth on the Leopard 45July 23, 2024. Our newsletter will provide you with the latest news, special offers, previews and shows Product updates and announcements. No spam. Evolving from 50 years of customer feedback, Leopard Catamarans has pooled their expertise with builders Robertson and Caine to design today’s Leopard range: spacious, robust, performance-driven blue water cruising catamarans.