Service Locator

- Angler Endorsement

- Boat Towing Coverage

- Mechanical Breakdown

- Insurance Requirements in Mexico

- Agreed Hull Value

- Actual Cash Value

- Liability Only

- Insurance Payment Options

- Claims Information

- Towing Service Agreement

- Membership Plans

- Boat Show Tickets

- BoatUS Boats For Sale

- Membership Payment Options

- Consumer Affairs

- Boat Documentation Requirements

- Installation Instructions

- Shipping & Handling Information

- Contact Boat Lettering

- End User Agreement

- Frequently Asked Questions

- Vessel Documentation

- BoatUS Foundation

- Government Affairs

- Powercruisers

- Buying & Selling Advice

- Maintenance

- Tow Vehicles

- Make & Create

- Makeovers & Refitting

- Accessories

- Electronics

- Skills, Tips, Tools

- Spring Preparation

- Winterization

- Boaters’ Rights

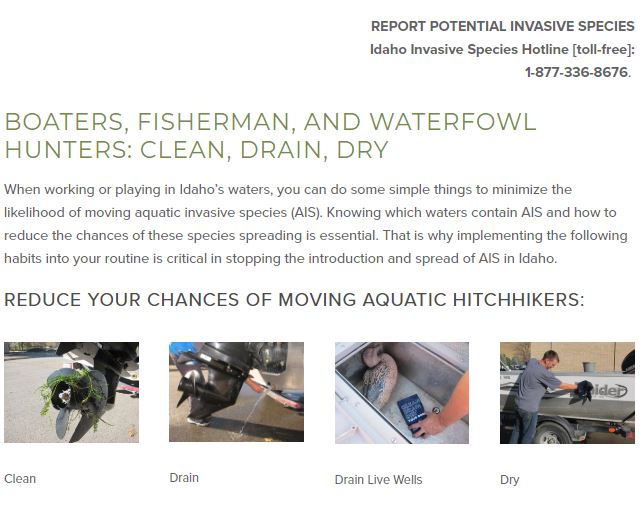

- Environment & Clean Water

- Boat Safety

- Navigational Hazards

- Personal Safety

- Batteries & Onboard Power

- Motors, Engines, Propulsion

- Books & Movies

- Cockpit Confessions

- Communication & Etiquette

- Contests & Sweepstakes

- Colleges & Tech Schools

- Food, Drink, Entertainment

- New To Boating

- Travel & Destinations

- Watersports

- Anchors & Anchoring

- Boat Handling

Boat Evaluation Checklist

Advertisement

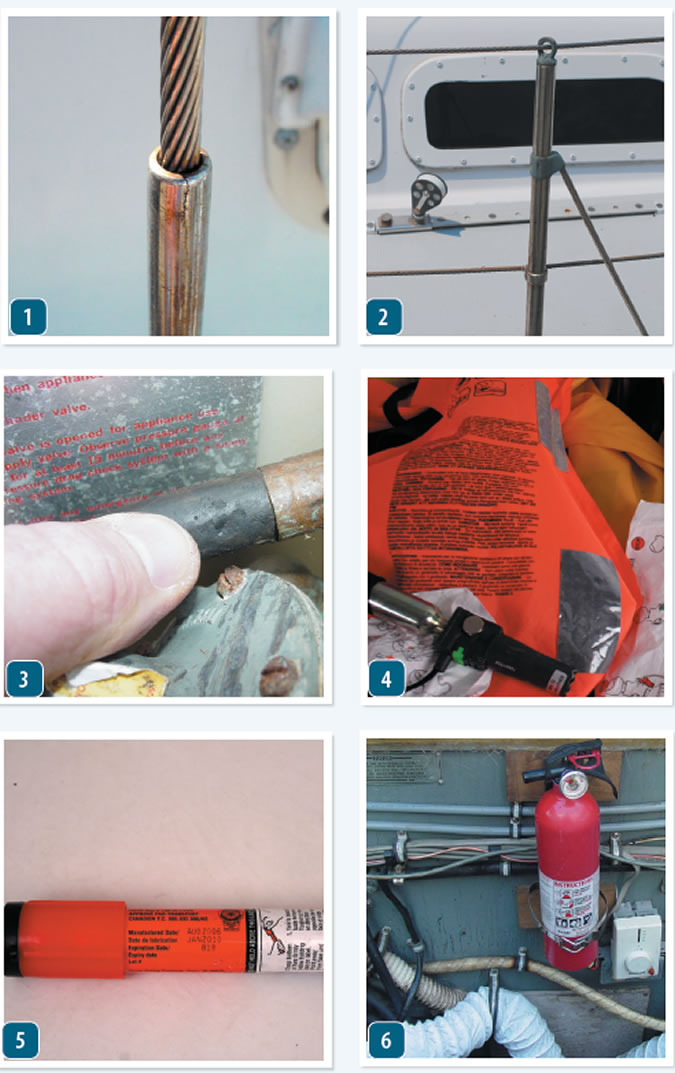

Evaluating a boat's condition is essential before purchase. New boaters and boat buyers can use this checklist to make a preliminary evaluation.

Evaluating a boat's condition before purchase makes it easier for the prospective owner to say "good buy" or "good bye" to a deal. Likewise, an objective eye for problems that need to be corrected makes it easier to prepare a boat for sale.

Use the checklist below to make a preliminary evaluation:

- Make copies for each boat you look at

- You may want to keep shopping if your evaluation has more than 10 scores of 2 or under.

- Is it clean?

- Are there signs of rust, hull blisters, peeling paint or varnish, previous repairs, cracks or corrosion?

- Don't forget to check operating gear like winches, steering systems, running and standing rigging on sailboats, lights, head and galley equipment, electronics and instrumentation.

- Start up the engine and take a sea trial.

- Check for compliance with U.S. Coast Guard safety equipment requirements

This checklist is NOT a substitute for inspections by a competent marine surveyor and a marine engine mechanic.

Related Articles

The truth about ceramic coatings for boats.

Our editor investigates the marketing claims of consumer-grade ceramic coatings.

Fine-Tune Your Side Scan Fishfinder

Take your side-scanning fishfinder off auto mode, and you’ll be spotting your prey from afar in no time

DIY Boat Foam Decking

Closed-cell foam flooring helps make boating more comfortable. Here’s how to install it on your vessel

Click to explore related articles

BoatUS Editors

Contributor, BoatUS Magazine

Award-winning BoatUS Magazine is the official publication of Boat Owners Association of The United States. The magazine provides boating skills, DIY maintenance, safety, news and more from top experts.

BoatUS Magazine Is A Benefit Of BoatUS Membership

Membership Benefits Include:

Subscription to the print version of BoatUS Magazine

4% back on purchases from West Marine stores or online at WestMarine.com

Discounts on fuel, transient slips, repairs and more at over 1,200 businesses

Deals on cruises, charters, car rentals, hotel stays and more…

All for only $25/year!

We use cookies to enhance your visit to our website and to improve your experience. By continuing to use our website, you’re agreeing to our cookie policy.

Boat Inspection Checklist: 31 Important Steps (Complete Guide)

Buying a new (or used) boat is one of the biggest financial transactions in your life.

It’s important to carry out a thorough inspection before putting money on the table.

In this article, we cover the essential things to remember when inspecting a new boat. This checklist will help you determine the state of the vessel so you can get the best value for your money:

Table of Contents

Important Areas to Cover in a Boat Inspection Checklist

Before buying a boat, it helps to take a frank look at every aspect of the vessel to ensure that everything is in perfect condition. This helps you avoid costly pitfalls.

It also allows the seller to identify things which can affect the salability of their boat.

A marine surveyor can help you identify defects in a new boat. However, it is important for you to know what to check when making such a huge deal.

The following are the main things to inspect before buying a boat:

- Operating Gear

Exterior Inspection Checklist

The exterior of a boat is the most important part of the vessel as it is in direct contact with the water.

Any exterior faults that you didn’t catch prior to buying can cost you thousands in repairs.

It can also reduce the excitement of owning a boat. Use this checklist to make sure all is well.

You want to start your inspection with a quick walk around the boat for a general look.

Check out the appearance of important parts of the hull such as the strakes, chines, and stem. Are there any cracks, peeling paint, and depressions?

Tap the entire hull with the plastic handle of a large screwdriver or mallet. If you hear a solid “thunk” sound, that’s a good sign.

A high-pitched or dull sound is a sign of a void. Open cracks, stress patterns, and any obvious deformity is a telltale sign of accidents.

Examine the hull for blisters. A new boat shouldn’t have blisters, but minor ones are still tolerable. However, severe blisters suggest serious issues that need further investigation.

Not every hull problem is serious enough to rule out a boat.

However, any stress marks or cracks on the hull can compromise the boat’s ability to withstand a collision.

A weakened hull can hasten the effect of the harsh marine environment on the vessel. Mismatched paint on the hull indicates they have repaired the boat after completion. If you have any doubts, ask for professional advice.

The keel must run true in a straight line from fore to aft.

It should be straight horizontally and show no signs of damage or wear.

Your surveyor may need to get under the boat to have a good look at the keel.

Like the hull, the deck must be watertight and have no voids in the laminate.

Examine the deck for moisture penetration, voids, and delamination.

Using the tools stated above, give the whole deck a good wrap and keep an ear out for any odd sound. You want the deck to be sturdy and with no physical blemish.

Cracks, dents, depressions, soft spots, and fading paint indicate serious flaws that need thorough investigation.

If you hear a hollow sound after hitting the deck with a mallet, investigate the fiberglass and wooden panels for damage. Also, it’s important for the deck fittings such as cleats and chainplates to be watertight and free of damage.

4) Helm Station

Check that the steering is free and easy to move.

The dials should be fog and mist-free and the controls should have no signs of moisture. Test navigational equipment to make sure they are in perfect condition.

The transmission should shift easily with no noise. If it makes a clunky sound, something is wrong.

5) Hull-to-Deck Joint

You want your boat to come with glued, bolted or glassed hull-to-deck joints.

These are sturdier and longer-lasting than riveted or screwed joints.

Joint gaps should not be in the anchor locker, cabin furniture, and engine room as these are potential entry points for moisture.

6) Molding Trim

A new boat should have a fit and well-finished molding trim.

Check inside the cabinets and berths for any structural issues.

Fiberglass should bond the bulkheads to the hull for improved water tightness.

Putty or foam filets prevent the buildup of pressure between the hull and the bulkhead and make the structure stronger to prevent fiberglass cracks.

7) Hardware

Check that deck hardware such as outriggers, tops, windlasses, and towers are bolted firmly.

It’s best to use metal bolts with backing plates. Fiberglass or aluminum or stainless steel backing plates are best, but wood backing will also do the job.

It’s important for deck hardware to have some bedding compound for waterproofing.

If there are bulges of the compound at the bases of the fasteners, that shows they are leakproof.

8) Cushions

Check the quality of the upholstery.

Are there stains or watermarks on the cushions?

If you notice any deterioration because of water damage or wear, the seller may need to change them.

Hatches on the deck and transom should be watertight.

Check that hatches have latches, gaskets, and gutters for 100 percent waterproofing to prevent flooding.

Look for corrosion, excess caulking, and signs of damage. Check if the hatches open freely.

Also, look out for water and any odd smell in the compartments you access through each hatch.

Any gas odor or water may indicate a failed hatch.

10) Windshield

The windshield, top and side curtains must be secured properly to the deck.

Check for gaps that could allow rain and spray to reach the controls.

If the windshield cannot keep out water, your trips will be wet regardless of the weather.

11) Navigational Lights

You want all deck lights to be visible without obstructions.

Equipment, deck structures, and the position of the lights must not overlap to ensure maximum visibility all around the boat.

12) Life Rail

Inspect the rails and pulpit for fit and finish. You want the stanchions and life rails to be securely bolted to the deck.

Stainless steel stanchions and rails are stronger and offer better corrosion resistance, but are expensive.

Zinc aluminum railings may be more affordable and aesthetically pleasing at first, but they have poor corrosion resistance.

Check for rust signs at the point where the rails and the deck meet as that can lead to leakages.

Interior On The Boat To Check

The interior inspection involves checking the sole (cabin floor), layout, finish, galley, and sleeping accommodations.

13) Water Tightness

When below decks, you want to be warm, dry, and comfortable. Check every space for traces of water.

If there are signs of corrosion or watermarks, or peeling paint, ask questions.

Examine the cabinet spaces and stowage to see if the installation is solid. Check the fiberglass work for shoddy gluing or screwing as the fastening are potential water entry points.

14) Upholstery

Does the upholstery provide the level of comfort you desire in a boat? Examine the material used for cushions, tables, and chairs.

In the marine environment, specialized fabrics and cushion materials are the proper upholstery materials.

15) Cabin Security

The cabin should provide adequate levels of security. Cabin hardware should be secured properly.

Ensure that the exhaust fumes from the engine do not seep into the cabin.

There should also be a cutoff switch for the propane tank source. Check that the sink drain and other through-hull hoses connect properly to a through-hull fitting with a seacock valve.

On rough waters, poorly secured china, dishwashers, and other appliances can become projectiles. Galley equipment should be bolted and back-mounted so they don’t move freely when you hit stormy waters.

Freezer and refrigerator doors should not have hinges on the stern side to prevent them from opening when the boat is on a plane.

The stove, propane storage, sink, faucet, and other appliance should be installed, working, and well secured.

Also, inspect the sleeping accommodations, doors, furnishing, latches, and drawers. Examine the air conditioning and entertainment systems for proper installation and operation.

17) Locker Space

Does the boat have enough locker space? Are the lockers easily accessible and waterproof?

Are the lockers secure enough to keep their stores from spilling on rough waters? You want your lockers to be roomy, stable, and secure for every circumstance.

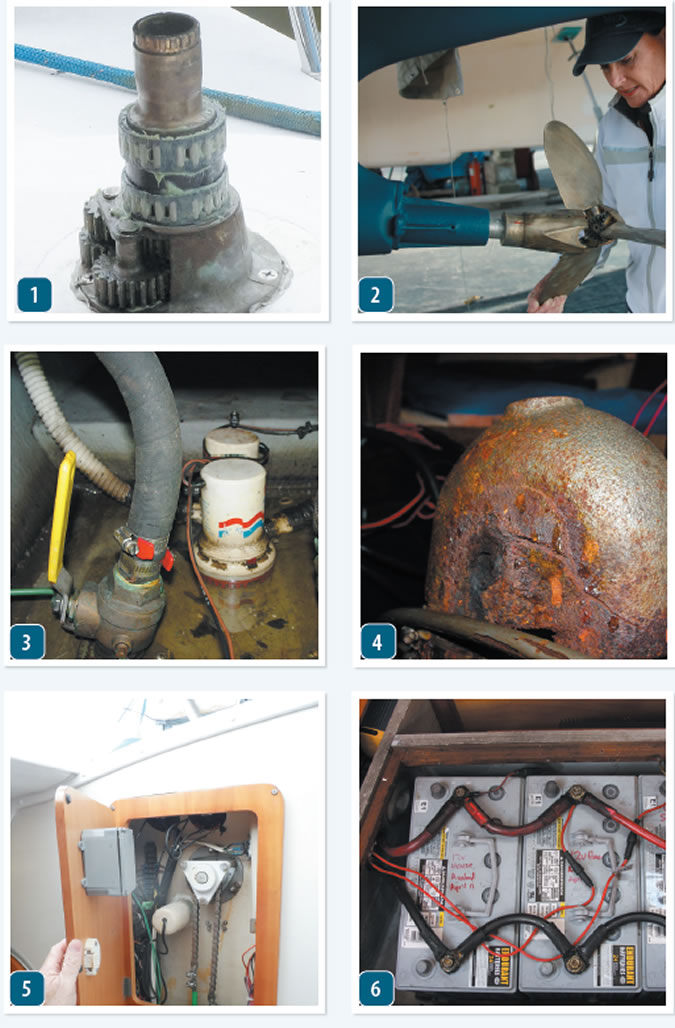

Operating Gear You Should Check

The engine, electrical systems, and propulsion systems of the boat should be in top shape.

Here are things to cover in the operating gear inspection:

Carry out extensive tests on the engine to certify it is OK.

Do a thorough inspection and evaluation of the engine, engine room, beds, and mounts.

Check that the engine hatch opens easily and vent hoses should be free. The engine numbers must match those on the contract.

A good way to know the engine’s state of health is to run it at full throttle underway.

If the engine overshoots or does not reach the manufacturer’s maximum rpm range, something may be wrong with it or the propeller. You also need to inspect the drive train and every other accessible component.

Check that the height of the exhaust risers is above the waterline to prevent back flooding. It should also be fastened securely with proper support.

Examine the exhaust for holes as this can allow water and exhaust gas into the interior space and bilge of the boat.

Also, check that the engine coolers are working properly and the raw-water intake hoses are double clamped on each end.

19) Engine Oil

Test the engine oil for water, grit, color, and odor.

If it smells burned or has water, there might be a crack in the engine block. Milky slimy oil indicates serious engine problems.

The fuel lines and fuel filter must be free of debris and condensation.

Otherwise, the engine will lose power and sputter periodically. and is at risk of being damaged.

20) Propeller

The propeller shafts should be straight and true. They should be sound, sturdy, and have strong support.

Check that the shaft’s flange and that of the transmission have no gaps or offset at the point where they meet.

If the boat has an inboard prop, check that the distance between the hull and each tip is the same.

21) Steering

Check that the rudder’s motion is smooth and easy. Inspect for water seepage in the rudder and check the hinges for wear and looseness.

A good way to check for low fluid or leaks in the steering wheel is to turn it from lock to lock.

Above seven turns suggests loose steering.

You want the rudders to turn fully to their stops. The hydraulic steering pump should be the ideal size specified by the manufacturer.

The autopilot and hoses should be in excellent condition.

22) Battery

Check that no systems (except bilge pumps) are wired directly to the battery.

All DC gear should come online and offline when you turn the main battery switch on and off. The automatic bilge pumps are the only gear that should stay on.

A battery that has been idle for over two months could have lost over 35 percent of its charge.

Also, check that the alternator is delivering adequate power to the battery. And test the battery charger to make sure it delivers the proper charging voltage.

23) Wiring Connections

Check to make sure that all electrical installations comply with sound practices and safety requirements.

Make sure there are no loose and bare wires, including connections sealed with electrical tapes.

Also, test to see that the electrical equipment functions properly.

Test for stray current leakages on the boat.

Inspect the bilge and bilge pumps to make sure they work properly.

The automatic bilge pump should work when the DC power is turned off and come with a manual override control.

Inspect the fuel, pressure, and oil gauges for proper installation and operation.

Test every control system that provides vital information about the vessel for improved situational awareness.

26) Plumbing

Make sure every component of the plumbing system works perfectly.

Test seacocks to see whether they open and close easily.

Inspect and test the toilet, shower, pump, faucet and every part of the head.

Check strainers, screens, and hoses for cracks, brittleness and leaks. Damp or moldy smell and water stains or puddles may indicate a leak somewhere in the plumbing system.

Is the head and holding tank accessible, or do you need to unscrew parts of the boat to empty it?

You want the system to have a Y-valve so you can disable the direct discharge option while in port. Whatever you do, make sure the head or holding tank is easy to clean and large enough for the number of people who will spend time on the boat.

27) Fuel System

Inspect the tank, fuel filter, tank and mounts, shutoff, and fuel lines.

Make sure there are no leaks and the compartment is watertight.

28) Mast and Rigging

For sailboats, you also need to inspect the mast and rigging for the following:

- Check that the mast, boom, and poles are in great shape.

- Examine all moving parts including the masthead sheaves, associated blocks, winches, and welds.

- Inspect the rigging wire for chafing and broken strands and other connections.

- Look out for cracks, corrosion, and deformities in the eye terminals.

- The mast should be even, straight and sound without damage, corrosion or surface defects.

- Examine canvas attachments, fittings, and spreaders for chafing, wear, and corrosion.

29) Safety Equipment

Inspect and test to make sure the automatic fire suppression system is installed and working properly.

Find out the quantity, size, and type of fixed fire extinguishers on the boat. Make sure they comply with Coast Guard and local requirements.

The boat should have visual distress signals, navigation lights, and audible signals.

Smoke detectors, carbon monoxide detectors, personal floatation devices, and first aid kits should also be available. There should be adequate ventilation for the engine room and the exhaust pipe.

You want to inspect the various lines and cables for chafing, wear, and corrosion.

Check the anchor and throttle cable for effects of corrosion because they are often more exposed.

31) Check for Missing Parts

Is anything out of place? Look out for stray bolts and screws around the boat.

If you see a hole that seemed to hold something or exposed wires, somebody may have removed something from the vessel.

Who Should Carry Out a New Boat Inspection?

For best results, hire a qualified marine surveyor for a detailed boat inspection before signing any deal.

Avoid people who only work on the docks but parade themselves as a marine surveyor.

Ask for referrals or contact the marine surveyors’ associations for a professional near you.

It may surprise you that new boats require such extensive checks and inspections. However, many people have learned the hard way after splurging on their dream boat and getting a huge disappointment.

You don’t want to be that person.

How Long Does a Boat Inspection Take?

The actual duration of a boat inspection depends on several factors. It takes about a day to complete inspections on most small boats.

Bigger vessels such as yachts and large catamarans may need more than a day.

The surveyor may inspect a boat in the water during the summer in a day.

However, bad weather, the yard’s schedule, time of the year, and the location of the boat can all delay or expedite the inspection process.

The scope of the inspection is also an important factor. While some inspections are limited to the examination of the boat systems, bottom cleaning, and a short-haul, some are more detailed.

If you want a comprehensive inspection and testing of the engine and other vital systems of the boat, the marine surveyor may require more than a day to complete the job.

On sailboats, you may also want to check the masts and rigging.

After the inspection, the surveyor needs time to draw up a report appraising the health of the boat, findings, and recommendations.

The time you need to complete a boat inspection depends on the state of the watercraft and the complexity of its systems.

If the boat is in top shape, there won’t be much to investigate. However, serious flaws in the construction and noncompliance with regulations and standards mean further investigations.

Sometimes, you may need a professional to check things out before you can complete the inspection.

What Is the Cost of a Professional Boat Inspection?

The marine surveyor may charge a flat rate or an hourly rate. If he/she uses a flat rate, it will be based on the length of the boat.

Rates go for around $20 per linear foot on smaller boats. The price increases with the size and complexity of the vessel, especially if you are inspecting an old boat.

For a rough estimate, determine the length of the boat and multiply by $20.

Meanwhile, other factors can increase the pricing of the inspection. An engine survey can set you back by $500.

If the hull is dirty and needs a pressure wash, it costs around $15 per foot, and the bill may be on you. Negotiate this with the seller.

However, the seller would pay for the fuel and the captain if that is necessary.

How to Reduce Boat Inspection Costs

You can reduce the inspection cost by assisting the surveyor.

Don’t leave things that you can inspect yourself to the professional. Help him/her to open hatches, pull gear, test appliances, and remove items that could disrupt the workflow.

If you notice a flaw that changes your mind about buying the boat, tell the surveyor to inspect it immediately.

If the issue is serious enough to disqualify the boat, stop the inspection right there.

That way, you don’t waste the surveyor’s time and save money.

Marine Diesel Engine Checklist

If a diesel engine takes a huge chunk of a boat’s value, it’s important to perform a detailed survey of the machine before and during the sea trial.

During the inspection, check for visual flaws and keep your ears open.

Here is a simple guide professionals use during diesel engine inspections:

Inspect the Engine Installation:

Examine the following parts for wear and damage:

- Engine beds : Check for cracks, water/oil mixture, and puddles of water or moisture.

- Engine motor mounts : Examine the mounts for cracks, misalignment, and distortions.

- Engine coupling shaft : Are these properly aligned? Check that they are bolted properly and the fasteners are in good condition.

- Any cracks here can cause water to seep into the engine block.

- Also, make sure the two ends of the hoses are clamped. The hose clamps should be free of corrosion, wear, and not too tight.

- Wiring : Electrical connections at the engine and batteries should be insulated. Look out for electrical tapes and naked wires.

- Engine Belts : Depress each engine belt gently with your thumb. If the depression is over 1/4″, there is a problem.

Gaskets and Seals:

Inspect the block, manifold, and oil pan for leaks and heat spots as they indicate overheating.

Examine seals on the injectors, fuel lines, and lift pumps.

Check for leaks around the fuel tanks and fuel filters. What does the place smell like? Diesel, damp or oil?

Check the Dipsticks:

Read the dipsticks of the oil sump and transmission gearbox.

Don’t clean the dipstick with a cloth; use your hand.

If the oil feels gritty or has particles, it is a sign of serious engine wear.

Check the color and reading in the second sounding. If the lubricant smells burned or appears milky or bubbly, the engine block might be cracked.

Check the Impeller Housing:

Examine the impeller vanes for wear and distortion.

If you find chips, this needs to be addressed.

Inspect for Zinc anodes:

Inspect the zinc anodes on the propeller shaft or hull, as well as in the engine heat exchange if they are used.

A fully compromised shaft zinc can’t perform its function to prevent corrosion of the drivetrain, so that is a serious problem.

Test the Engine Live:

Run the engine at full throttle to identify hidden flaws.

Power the engine to the maximum and check for the fluctuations of the RPM, oil pressure, and water temperature.

Also, examine the stuffing box for leaks, check shaft alignment and hose-to-fitting seals for leaks.

Final Words:

A lot of things can go wrong with a new boat, but a comprehensive inspection can help you avoid buying a money guzzling vessel.

The best you can do is to get a qualified marine surveyor to help with the inspections.

But if you can’t hire a surveyor, it helps to know what to look out for.

And that is why we researched and created this extensive inspection checklist for when you want to buy a new boat.

We hope this article helps steer you in the right direction as you go boat shopping!

Click to share...

Home » Blog » Buy a boat » The ultimate boat survey checklist

The ultimate boat survey checklist

By Author Robin Urquhart

Posted on Last updated: August 28, 2021

Photo credit: taduuda

You’ve found a boat to buy that looks good on paper, but what horrors lurk beneath? Time to do a deep dive with a full marine survey.

Part of our “how to buy a boat” series.

Conducting a marine survey can be a very fun task. It is our first opportunity to really get to know a boat. We always conduct a mini-survey and have some idea of what the boat is about, but it’s not until we get down to the nitty-gritty that we really see what’s going on.

We have developed a list of actions and things to look for in a full blown marine survey. Most of this doesn’t require any specialized knowledge, just a pair of latex gloves and keen eyes. Our marine survey does not replace, nor should it, a professional marine survey. If we are happy with the result of our survey, we’ll make an offer on the boat and make a term of the offer our approval of a professional marine survey. But due to the cost of a professional survey, which is usually north of $500, we reserve this service for when we are really serious about buying the boat, which is why our own survey is so important.

The following is a breakdown of items to check, how to check them and our experience. It may not be possible to go through everything in this list, but it is worth trying. We have found the full survey takes us anywhere from 2-4 hours. Sometimes we have to break this over a couple of trips depending on the owner’s schedule. We have found it works best if the owner isn’t breathing on our necks the whole time, but that can also present the opportunity to ask a lot of questions. We have been burned a couple of times by dishonest owners so we take their answers with a grain of salt and check everything no matter what they say.

We’ve included a FREE boat survey worksheet at the bottom of the post that you can download and take with you on your next boat visit.

Boat Survey Checklist

Blisters. 4

Cracks (especially at keel hull joint) 4

Bottom paint condition. 4

Soft spots/hollow spots. 4

Scratches or chips in the gelcoat, evidence of filler 5

Thru-hulls. 5

Grab rails. 6

Life lines. 6

Thru-decks. 7

Chainplates. 7

Soft spots. 7

Cracking. 8

Mast electrical 8

Shrouds and stays. 8

Lines and sheets. 8

Antennae. 8

Propeller 9

Propeller shaft and strut 9

Below deck. 9

Keel bolts. 10

Water staining. 10

Rust and corrosion. 10

Thru-hulls. 10

Bulkheads. 10

Chainplates. 11

Mast step. 11

Locker doors. 11

Interior woodwork. 11

Upholstery and cushions. 11

Comforts. 12

Cleanliness. 12

Spare parts. 12

Electrical 12

Batteries. 12

Lighting. 13

Electronics. 13

Additional items. 13

Check from multiple angles and in different conditions. The blisters are often only slight undulations and can be hard to see. Evening and early morning light where the sun’s rays are at an acute angle to the hull are especially good times to view. Blisters are often most visible after a couple of days of the boat being out of water and as the hull begins to dry out. They can appear as small wet spots (usually about the size of a dime or quarter) or areas where paint has chipped off. If the hull has been out of the water for a few weeks or months, the blisters may have dried out and will be more difficult to see. If the hull is not clean or has a buildup of many layers of bottom paint, blisters can be extremely difficult to detect.

Our experience

Our latest boat had a lot of blisters, which we didn’t notice until we began scraping paint off the hull. We scraped over 100 lbs of paint off the hull and it was worst build-up we have ever seen. Underneath were a lot of little blisters. Luckily they were all very small and mostly in the first layer of fibreglass. I drilled them out with a dremel and filled them with epoxy after letting them dry out for a week. It was not expensive, or dangerous, just time intensive. In the end we repaired about 150 blisters.

Cracks (especially at keel hull joint)

Check for a crack between the hull and keel. In some boats this may appear as a ‘smile.’ Check the bottom paint for cracking as it may not be obvious. If the boat has recently come out of the water, the crack may appear as a slightly wet area or discoloured. If the hull is not clean it can be difficult to detect cracks. Also check the bow area and front of the keel for any cracks or signs of stress.

Bottom paint condition

Scraping bottom paint is a time intensive job. If multiple layers of bottom paint have built up it is an indication that the owner has not been putting much time into maintaining the boat. A build-up of bottom paint will slow the boat down and make it difficult to see nascent issues such as osmosis blisters.

OMFG what a terrible job. It took us and my parents two weeks of straight scraping and chemical treatment and sanding to get the hull down to gelcoat again. We would be very wary to do it again. Again it is sweat equity and we, at times, enjoyed the process, especially the finished product.

Soft spots/hollow spots

Tap on the hull with a 4oz. Hammer or some other light, metallic implement. Listen for the sound it makes. The sounds can be difficult to interpret as anything bonded to the hull, like bulkheads or water tanks, will make the tap sound sharper. Listen for especially dull taps in a cored-hull as they may indicate water intrusion into the coring. This is a big problem and should be reviewed by a professional surveyor if in doubt.

We have never done this and we know very few people who do. A good surveyor will always do this, but it is difficult to interpret the sounds unless you have a lot of experience. Really dull thuds are obvious of course. In the future we would definitely do this.

Scratches or chips in the gelcoat, evidence of filler

Look around for signs of impact or stress on the hull. Often boats glance off docks or other obstructions and create scratches or chips in the gel-coat. Tap these small areas closely to ensure no structural damage has occurred. Most of time there is no problem.

Our boat had filler in many places on the hull above the water line. Apparently the previous owner(s) were not adept at docking. The scratches didn’t look like they went beyond the gelcoat so we didn’t think much of it. In the end we added a bit of cosmetic filler and paint and it was never a problem. Looking back, we should have checked around these areas just to be sure. Lucky.

Check around thru-hulls for any indication of damage, failed sealant, corrosion or blockage. Below water thru-hulls cannot be made of plastic. This will appear as an insurance issue if it is not ameliorated.

If the boat is still in the travel lift slings, push on the keel from side to side. If it moves, there is an attachment issue. Check the joint between the keel and the hull for any cracking or signs of water intrusion. Look at the front and bottom of the keel for scrapes or damage which may indicate grounding. If the boat is already on stanchions, stand at the front of the bow and visually line up the keel with the centre line of the boat. If it is at a slight angle, there may be a problem.

The previous owner lied about grounding our boat. The lie was only apparent after we checked the front bottom of the keel and found a whole bunch of painted sealant. I had to grind it all off, fill the area properly and fibreglass over it again. It wasn’t a big deal, but could have meant structural problems. The big lesson to us was that seller’s lie, even when they appear to be nice, honest people.

Shake the rudder back and forth to check how much play is in the bearings. It should barely move. Have somebody on deck turn the wheel or tiller from side to side. Examine how the rudder moves. If there is a skeg, check the joint between the skeg and the hull. Shake the skeg. Tap the rudder with a small hammer and listen for dull thuds, which indicate water intrusion. It is quite common for rudders to be water-logged, which can deteriorate the bond between rudder core and support tangs. The movement of the tiller or wheel should be smooth and easy. Is the steering mechanism hydraulic or cable and gear? Check the condition of the hydraulic ram seals or the steel cable, gear and cable clamps.

We took our rudder off just to be sure and found the rudder post tube was in good condition. So we put it all back on and replaced the stainless steel wire and wire clamps.

Winches should sound like Swiss watches ticking when you slowly turn them. When were the winches last serviced? Do they have winch covers (this will prevent salt and grime entering them when they are not being used). How warn is the drum? Check all winches.

When we took apart our winches we found they were full of somebody’s long black hair. Ouch and yuck. After cleaning them thoroughly they ticked so much smoother. Winch maintenance should be done annually, but don’t be at all surprised if it is never done at all. It’s not a hard job and requires almost no materials. If they barely turn at all, then it is a much larger problem and winches are shockingly, like cosmic jokingly, expensive to replace.

Check cracking in the deck around the grab rails. Pull hard on the grab rails and note any deck deflection or movement of the rail itself. Check the fastener connection for indication of water intrusion through the fastener hole into the deck. Tap around the grab rails especially carefully for signs of water intrusion or damage.

Our grab rails were leaking into the deck and we had to rebed them. We took the opportunity to sand them down and apply oil rather than varnish, which requires less maintenance.

Check the life lines for signs of damage. Check carefully at the connection between the steel cable and the turnbuckle. If the lines are coated in plastic, check for cracking in the plastic and signs of rust. Stainless steel will rust under plastic sheathed life lines and you might want to consider replacing them if they are more than 10 years old.

We had plastic sheathed life lines and the stainless wire was starting to rust . We replaced them with straight stainless wire. We reused the turnbuckles. Swaging is costly if you don’t do it yourself and the fix ended up costing around $800.

Check sealant around the windows or discoloration, discontinuity or cracking. Is there any water staining on the inside of the cabin around the windows and hatches?

We replaced all the windows and hatches on our current boat. They were completely crazed and we could barely see through them. We went with plexiglass instead of Lexan because it was so much cheaper and doesn’t craze. But it is less strong, and we upped the thickness to make up the difference in some places. Bedding hatches and windows is messy and stressful. Check for sealant compatibility with different plastics. The best ones we know of are DOW 795 and GE Silicone II.

Check all thru-decks (especially hatches) for signs of cracking or water intrusion. When were the thru-decks last replaced?

Every thru-deck on our boat leaked. We didn’t really check them that closely when we surveyed the boat and it took two years to get all of the leaks sorted out. Many had been leaking for a decade or more and had caused significant rot. We had never tapped the deck with a hammer before we bought the boat and decided to do it before we outfitted it for a big trip. We used a pencil to mark areas that thudded. By the end, more than 30% of our deck was covered in pencil marks. I freaked out and immediately started looking on Yachtworld for another boat. A friend who owns a boatyard came by and took a look. He said, ‘no big deal’ this looks like the deck of lots of old boats.’ It took us a month of straight work to tear up the top layer of deck, replace the core and fibreglass over it again. It cost us about 1000 dollars in materials, but we did all the work ourselves. Thankfully Fiona is a wizard with bondo and you’d never know the deck had been refurbished. It’s better to find a deck without soft spots, but may not be possible. Note the extent and consider the time to fix it, or just live with it. At any rate, you’ll want to fix the leaks so they don’t get any worse.

Chainplates

Pull laterally on the stays and shrouds close to where they connect to the chainplates. Note any deflection. Check where the chainplate enters the deck or bolts onto the hull. Is there any cracking or discoloration? Is the metal in good condition?

We saw a ramp bead of silicone around the perimeter of the chainplate above deck. It suggested the previous owner may have thought they were leaking. We have also heard that people do this as a preventative measure so it might also just be good boat maintenance.

Soft spots in the deck will appear as areas that deflect when you weight them or as dull thuds when you tap them with a small hammer. They indicate degradation of the core material and should be carefully investigated. Tap over the whole deck with a 4oz. hammer or similar and listen for the sound it makes. Dull thuds indicate water intrusion. Is the deck cored? What is the core material? Get somebody to lightly bounce in different areas of the deck and take note of any deflection.

We had tonnes. See thru-decks.

Walk the deck and check for signs of cracking. Especially check at the chainplates, mast and forestay. Large cracks can indicate stress and deformation of the deck. Small cracks, called spider cracks, are common in the gelcoat of older boats and do not necessarily represent a problem.

Our boat looks like a spider web in some places. We’ve learned to live with it.

Mast electrical

Check where the wires exit the mast and enter the boat for signs of water leaks. If it is a deck stepped mast, there will be holes in the deck to allow for the electrical wires. Does all the mast electrical work? Try each light and make sure you can see it working. Rewiring a mast is a big pain.

We rewired our mast when it was taken off for re-rigging. We replaced all the lights at the same time. It was relatively straight forward, but remember do not pull out all the wires without leaving in a messenger line or some way of pulling new wire through.

Shrouds and stays

It’s scary but it’s a good idea to go up the mast and check the shrouds and stays for any signs of damage. Most often the damage will be where the stainless steel wire connects to the turnbuckle. The turnbuckle might have a hairline crack in it, or you’ll see a broken strand or two of wire.

I climbed the mast of our boat while it was swaying around on a mooring. It had mast steps, which made it easier, but I was still pretty nervous. I don’t even remember looking at the shroud or stays, as I moved through 12 feet of arc at the top of the mast. I just came back down and told Fiona they looked fine. Maybe they did.

Lines and sheets

Check the condition of the running gear. Is it worn or stiff? Stiff rope can often be soaked into suppleness, but chafed line needs to be replaced. Is there spare line onboard?

We replaced all the running rigging slowly over time. It is a maintenance cost. Luckily there was a lot of spare line onboard and we saved a bundle as a result.

Check the binnacle compass. If there is an air bubble, the seal has failed moderately and may eventually need to be replaced. Is the compass adjustable for the magnetic elements on the boat?

Check the age of the antennae and turn on the VHF to make sure they work.

It’s usually not practical unless you are sailing to haul up a sail, but get as a good look as you can at them. Chafe, holes, patches or other repairs usually indicate that the sail has been around a long time. Also, its stiffness is a good indicator of its age. A really supple sail is probably old and tired and will need replacing soon.

We had super bagged out sails that we used for a couple of years of cruising. We weren’t the fastest boat, but we were fine. It’s amazing how long you can keep a sail going. We replaced the sails when we decided to cross an ocean. Having a sail tear out there was too scary a thought and we realized that performance over 10 000 miles actually matters.

Check the size and pitch of the propeller. Is it appropriate for the boat? You can check online with a propeller calculator. It is shocking how many mis-sized props there are on boats. They are expensive and can be finicky to replace.

Our prop was too big and overloaded the engine causing it to overheat. We had to replace the prop.

Propeller shaft and strut

Put the engine in neutral and spin the propeller. Check the trueness of the shaft. Shake the shaft back and forth, is there much play in the cutlass bearing? When was the bearing last replaced? Shake the strut back and forth, does it move?

We replaced our cutlass bearing, which required have to be sawing it out of the tube. This actually is a normal way to do it. It was a little scary sawing away, but if you go slowly and carefully it isn’t hard.

Is there water in the bilge? Can you see the tops of the keel bolts? What do the bilge pump and hose look like? Is there any visible deformation or cracking

The previous owner had changed the engine oil into the bilge a few times. There was a lot of water in the bilge and the bilge pump didn’t work. It took Fiona a whole day to clean it out properly. We bought a new bilge pump and replumbed it. It ended up costing around $300. The bilge pump needs to be secured as well, or it may be an insurance issue.

Ask the owner when the keel bolts were last checked and research how the keel bolts are attached to the keel. Is it a lead keel, or iron. Are the bolts thru-bolted or are they cast in place. What type of metal is the keel bolt? Keel bolts are not often replaced, but it is a good idea to check them at least every ten years. Some recommend replacement as well. It is often a very difficult job to check/replace keel bolts, so approach this with a grain of salt. There may be nothing you can do in the survey, but it could become a bargaining point later.

Our keel bolts were leaking and we kept getting water in the bilge and rust stains down the side of the keel where the bolts exited. We took our keel bolts out one by one and rebedded them. The whole job took three weeks. Not for the faint of heart.

Water staining

Check around the interior of the boat for water stains. Especially on the underside of chainplate connections, hatches and windows and any thru-deck location.

We had a little water staining at first glance, but that was only because the owner had cleaned it up before we came to look at the boat. It took us a year to stop all the leaks. See thru-decks.

Rust and corrosion

Check metal fittings for signs of rust or corrosion.

We had a lot of ferrous metal we had to remove. The wire clamps for the steering assembly were just little balls or rust and I had to cut them off with a zip cut. It was further proof to us that the previous owner was not maintaining the boat well.

Operate each thru-hull to make sure it works. Check for corrosion and hose connections. The thru-hull hose connection should have two gear clamps. If the thru-hull is stuck do not crank it very hard.

Only one of our thru-hulls didn’t work and we had to replace it. The effluent thru-hull appeared not to work, but with the application of some cleaner and oil we got it moving again. We have heard of surveyors breaking thru-hulls and having to call the owner to let them know their boat is sinking.

Where possible check the connection between bulk heads and the hull/deck. If the bulkhead is out of place, it suggests a major collision or other deformation of the hull/deck.

Check the underside of the chainplates for signs of water intrusion and corrosion. A chainplate issue can be a big deal, so if in doubt seek professional advice.

One of our chainplates was leaking, which we noticed as a brownish stain on the inside of the cabin top. The bedding sealant had degraded over 35 years of life and needed to be replaced. We rebed all the chainplates when we took the mast off for re-rigging. It was one of the easiest jobs on the boat. It would have been a different story if we noted any corrosion in the chainplate. This is a big issue and may require the involvement of a professional.

Does it work? Does it smell?

Check the connection above and below deck of the mast. For a deck stepped mast, check the top and bottom of the compression post as well. Lift the sole panels and actually visually inspect where the compression post of the mast connects to the keel and to the deck. Feel around for rot or corrosion. The same goes for a keel stepped mast. Check where it connects to the keel and where it passes through the deck for signs of leaking or corrosion.

We found one boat with bad corrosion of the keel stepped mast. The aluminum on the iron of the keel had begun to break down. It required having to pull the mast and make significant repair. That’s a big job and we walked away from the boat.

Locker doors

Do the locker doors all open and shut? If not, it could suggest a deformation of the hull or deck and should be investigated further.

Interior woodwork

Is the interior wood work in good condition.

Sanding interior wood work is a pain. Floor boards are quite expensive. To replace the floor on our Dufour 35 would have cost 2k. We have lived with ugly, partly rotten floor boards as a result.

Upholstery and cushions

In what condition is the upholstery. Do you like the color? Is the cushion foam firm/comfortable?

Replacing cushions is terribly expensive. We learned to live with a color we didn’t like and reused the cushions when we reupholstered. Budget anywhere from $1000-$4000 for new cushions.

Does it have a shower or hot water? Do they work? How old is the hot water heater? Where does the shower drain?

Depending on your location you may very well want a heater to keep the boat warm at times. They can be very expensive and require additional fuel lines, not to mention an exhaust port or chimney. They can run up to $1000 pretty quickly.

Check the suppleness of the hoses. Check the connections for signs of leaks and deterioration. Older hoses should be replaced.

How many hours does the engine have? Was it rebuilt?

Cleanliness

How clean is the engine? A clean engine means the owner appears to be maintaining it well. It is also easier to spot any leaks or other issues. Can you smell oil or diesel?

Spare parts

What kind of spares come with the engine? Spares can be pretty expensive so a list of spares is a boon, it also shows the owner is maintaining the boat well.

If the engine is freshwater cooled, check the heat exchanger zincs.

We have met a few boat owners who are not changing their heat exchanger zincs, which can lead to a breakdown of the exchanger rods. If the rods start leaking the heat exchanger will need to be replaced. There is also a risk of getting saltwater mixed in with the coolant and causing damage to the engine.

Check the batteries. Are their signs of terminal corrosion or dried powder on the tops of the batteries? How old are the batteries? How many amp hours is the battery bank? Is there room for additional batteries?

Check the wiring behind the AC and DC panels. Does it look neat and tidy? Are the connections done properly? How old are the panels? Do individual breakers have multiple connections to them?

We had to replace our DC electrical panel to make room for additional electrical systems. At the time we found the previous owner had not done any connections properly so we redid them all. It is relatively easy to do and doesn’t take long. We were really intimidated by redoing the electrical but it turned into our favorite job on the boat. Fiona is an electrical wizard now.

Check the type of lights. Are they LED or fluorescent or incandescent? LED lights can be pricey, figure $10 per bulb. Make sure all the lights work. If some don’t it could indicate a larger electrical problem.

Electronics

What electronics are on board? Do they all work? How old are they? Do they network with each other, ie. radar and gps, depth sounder and gps? Is there a functioning wind speed indicator?

Additional items

Ask about some important additional items, namely; dinghy, barbecue, anchors, fenders, dodger/bimini, winch covers, additional sails, solar panels, radar arch , wind generator, life vests, engine spares.

Here’s a quick boat survey checklist worksheet to take with you on your next boat inspection: Boat survey worksheet

Robin was born and raised in the Canadian North. His first memory of travel on water was by dogsled across a frozen lake. After studying environmental science and engineering he moved to Vancouver aboard a 35’ sailboat with his partner, Fiona, with the idea to fix up the boat and sail around the world. He has written for several sailing publications including SAIL, Cruising World, and was previously a contributing editor at Good Old Boat.

Terms and Conditions - Privacy Policy

- Articles and Guides

Boat Inspection Checklist: How to Inspect a Boat Before Buying

25th may 2024 by samantha wilson.

Boat inspections before purchase are vital to be sure you’re buying a sound boat and spending your money wisely. Use this checklist as your guide as we walk you through every step of the process. If you’re still early in the boat-buying process, we recommend you read our in-depth article How to Buy a Boat: The Ultimate Guide as well as learning what others got wrong by checking out the 9 Mistakes to Avoid when Buying a Boat .

There are differences when it comes to buying new and used boats; conducting inspections and knowing what to look for when buying a used boat are vital. Fresh out of the factory, boats won’t require this and will come with warranties to ensure everything is as it should be. When it comes to used boats, however (whether you’re buying a used boat from a private party or a broker), inspections are vital to make sure you’re buying a sound boat and spending your money wisely. There are many steps to buying a used boat , and viewing a boat you’re interested in is the very first one. It will give you that all-important first impression of the condition of the boat, at which point you decide to forge ahead or walk away. We highly recommend getting a complete marine survey done on any boat you’re considering buying, as experienced surveyors will know the problems to look for and where to find them.

But before you get to the stage of paying for a marine survey, have a read through our 7 Hidden Problems to Check for When Buying a Used Boat and use this checklist as a guide to make a thorough boat inspection before purchase.

Conducting inspections and knowing what to look for when buying a used boat are vital.

Pre-Inspection Checklist

- Ask to see servicing and maintenance records. Knowing a boat has had regular servicing and maintenance is a very good start and learning about past repairs may give you the chance to ask worthwhile questions. Ideally, the boat will have been serviced annually.

- Find out how the boat has been used. You can learn a lot with this question to give you insight into how well it has been maintained, where it has been used ( saltwater versus freshwater ), where it was stored, any damage that might have occurred, etc. Use it as a conversation starter and ask follow-up questions.

- Where has the boat been stored? In general, boats stored outside in the water are likely to have suffered more wear and tear than those stored in dry, covered conditions. The effects of close proximity to salt water, freezing water, and inclement weather can cause corrosion and damp. That doesn’t mean you shouldn’t ever buy a boat stored in the water—indeed one could argue that it may have been kept there because it was used more and therefore better maintained.

- Ask about any damage. While minor damage that has been repaired or is not visible might not be declared, it is still worth asking as it may raise previous issues you can mention later to a marine surveyor.

- How many hours does the engine have logged? Ask how many hours the engine has on it and when it was last serviced, as well its regular service program.

- Know what is included in the price. Make sure you ask the seller or broker to list exactly what is included at the asking price. This may include safety gear, electronics, or fishing equipment, for example. You’ll then want to ensure that the equipment is in good working order; otherwise you might be paying extra for what you could buy cheaper yourself.

- Is the boat still under warranty and is it transferable? Depending on the age of the boat, it might still be within its warranty, which is a valuable document to have in your possession. Ask whether the boat still has a warranty, how much time is left on the warranty, what the warranty covers, and whether the warranty is transferable to you.

Visual Boat Inspection Checklist

Start with a visual inspection of the exterior of the boat and get a feel not only for its condition but also its space and layout. Remember you want a sound boat, but you also want to choose the right boat for you , your family, and your specific needs.

- Check for damage or repairs. While cleanliness isn’t necessarily a sign of poor condition, it can raise flags as to how well the boat has been cared for. Check for cracks in the fiberglass, signs of repairs to the bodywork, scratches, or discolored areas where damage may have been repaired. If the boat is out of the water (which it should be at some point when viewed it), check for bubbles in the fiberglass indicating osmosis (these are difficult and costly to fix), and that there are no gouges or scraping on the bottom of the hull or keel that might become problematic down the line.

- Inspect the transom, decks, bilge, and fuel tank. The transom is where an outboard engine would usually be mounted. You want to be looking for any signs of waterlogged wood which could signal a major problem. While this is a less common problem in modern boats, older wooden boats are particularly susceptible to rot. Likewise, check the decks for signs of warping, rotting or softness from water intrusion. You’ll also want to check the bilge area for any signs of oil leaking from the engine, and the fuel tank for signs of corrosion.

- Ensure the stringers are well-connected. Stringers should be well connected to the hull, otherwise, the vessel is structurally at risk. While it isn’t always easy to see them, and you may need to venture into the bilge with a good light, it is a must. Any separation or damage should be treated with extreme wariness. If you’re not keen on getting down into the bilge, then mark this as something you want your surveyor to do.

- Rigging. On a sailing yacht, you’ll want to check the rigging and sails as these are expensive items to replace. On a regular cruising yacht, these typically should be replaced every 10 years, so ask when the current sails were purchased and if you can spread them out, you can inspect for damage or wear; the softer or more wrinkles you find in the Dacron material, the shorter the sail’s remaining lifespan.

If the boat is out of the water, check for bubbles in the fiberglass indicating osmosis, and that there are no gouges or scraping on the bottom of the hull or keel that might become problematic down the line,

Engine and Electrics

The engine is the most important part of any power boat, and you’ll want a professional to give it a thorough going-over before committing to a purchase.

- Check the oil. Ensure the oil doesn’t have a milky residue as this could signal water ingress. You can do this by pulling out the dipstick.

- Look for rust. Rust around the engine might indicate that the boat has been submerged in water for a long period of time, and its presence should set alarm bells ringing.

- Inspect the hoses, belts, and electrical connections. Have a close look at the hoses, belts, and electrical connections such as spark plugs to make sure they’re not cracked or worn.

- Check the propeller. Cracks in a propeller can be fixed, so aren’t always a red flag, but if you notice cracks or repairs, be sure to ask about them.

- Listen. Listen to the sound of the engine as it’s turned on and while running. You can do this during a sea trial, which is highly recommended, but also at the dock. Listen for excessive noise or vibrations, or unusual or rough sounds. Remember, boats don’t have odometers like cars, so it’s not easy to know how many hours a boat engine has run.

- Inspect the electrics. Rewiring is an expensive job on a boat, so spend time looking at as much of the electrical systems as you can. Start by switching on and off every single electrical item on board, before looking at the fuse box. A mixture of fuses might imply replacement, which in a newer vessel should raise some questions. Look at the wiring itself and get an idea of the condition.

The interior of a boat can give you a good idea of the care a boat has received and also highlight issues with the hull itself.

- Mold and mildew. Your first sign of interior mold and mildew is a strong, musty smell. Do a visual inspection too, looking for signs of rot on the floors or seating areas. Any warping is also a red flag.

- Leaks. Leaks in the hull may have been repaired and well hidden, so they may not be instantly visible. A good idea is to spray a hose at the hull, hatches, port holes, and seams and see if any moisture makes its way into the interior cabins.

- Check the doors, hatches, and windshield. As part of your visual boat inspection of the interior, be sure to open and close doors, portholes, and hatches to make sure they are watertight. The windshield should be secure with no cracks.

- Get a feel for the boat. As with the exterior, get familiar with the layout, style, and the décor. You may want to put your own stamp on the boat and design your own dazzling boat interior , but if not then consider the cost, if the soft furnishings are not up to par.

Get a Pre-Purchase Survey and Sea Trial

An inspection is highly recommended and will give you a better understanding of the condition of the boat before spending money on a pre-purchase survey (see our article Do I Need a Boat Survey When Buying a Used Boat? for more information). When it comes to pre-purchase surveys and sea trials , we almost always recommend having them conducted (unless the boat is very small or very inexpensive). An experienced marine surveyor will be able to do a thorough and in-depth report on the condition of the boat before you sign on the dotted line and provide you with the information to make a truly informed decision. You might want to run for the hills, or it might reassure you. You can always use the survey to negotiate the best price for a boat .

Rightboat.com lists thousands of used boats all over the world and is the best place to search for the perfect boat for you. We are here to help you every step of the way and have a huge resource centre filled with useful articles on buying a used or new boat . Please don’t hesitate to get in touch with our sellers, brokers, or the Rightboat.com team for more guidance.

This article was published in March 2021 and updated in December 2023.

Written By: Samantha Wilson

Samantha Wilson has spent her entire life on and around boats, from tiny sailing dinghies all the way up to superyachts. She writes for many boating and yachting publications, top charter agencies, and some of the largest travel businesses in the industry, combining her knowledge and passion of boating, travel and writing to create topical, useful and engaging content.

More from: Samantha Wilson

Related Articles and Guides

27th Jul 2024

Boat Survey: What It Is, Who Pays, Do I Need to Spend the Money?

7th Jun 2024

Best Boat Brands for Beginners: Power, Sail, Pontoon & Fish

4th May 2024

Do You Need a License to Sail a Boat in the US?

28th Nov 2023

Sea Trial: Costs, Checklist and More

- Explore Rightboat

- Boats for Sale

- Boating Articles

- Buyers Guide

- About RightBoat

- Sell Your Boat

- Boat Selling Advice

- All manufacturers

- All categories

Enter your email to keep up to date with the latest news

Join for free

Sign up now for free and discover how easy it is to keep up to date with THE latest boats for sale. Find your right boat, and tailor your voyage to finding your next boat.

Benefits of becoming a member:

- Set up tailored alerts

- Personalise your experience

- Download full specifications and broker details

- Keep tabs on your favourite boats

Are you a broker? Join as a Broker

Rightboat - join for free.

Do you have an account already? Login

Save this search

Save your search and receive new boats in your email..

You can unsubscribe from your alerts whenever you like. By pressing the button you accept the Legal Terms and conditions

Boat Inspection Checklist: 31 Important Steps

Owning a boat is not just about enjoying the open water; it’s about responsibility and care. Regular boat inspections are the cornerstone of responsible boat ownership, ensuring safety, preventing unexpected issues, and extending the life of your beloved vessel.

Imagine setting out on a perfect day for a leisurely cruise, only to encounter an avoidable problem that leaves you stranded or, worse, compromises safety. Such scenarios can be easily prevented through systematic boat inspections.

In this comprehensive guide, we’ll walk you through a detailed checklist for inspecting your boat thoroughly. From the bow to the stern, we’ll cover every aspect, ensuring that your boat is not only seaworthy but also prepared for many more memorable journeys. Whether you’re a seasoned mariner or new to boating, these inspection guidelines will help you navigate the waters of boat ownership with confidence and peace of mind.

Exterior Aspects of the Boat That Should Be Examined

- Hull Condition : Start your exterior inspection with a thorough examination of the hull. Look for any signs of damage, such as scratches, dings, or cracks. Pay close attention to the area around the waterline, as this is where the hull is most susceptible to damage.

- Gelcoat Condition : Inspect the gelcoat, which is the outer layer of the hull. Check for any areas where the gelcoat may be peeling, cracking, or fading. These issues should be addressed promptly to prevent further deterioration.

- Rub Rail : Examine the rub rail that runs along the boat’s perimeter. Check for any damage, such as dents or sections that may be coming loose. Ensure that it is properly aligned and securely in place to protect the hull from collisions and wear.

- Transom and Swim Platform : Inspect the transom, the vertical surface at the back of the boat, and the swim platform if your boat has one. Look for any damage or signs of wear, especially around areas where accessories like transducers or swim ladders are mounted.

- Bow and Anchor Area : Move to the bow of the boat and inspect the anchor and its components. Ensure that the anchor is securely stored and that the anchor chain and rode are in good condition. Check for any signs of corrosion or damage, as these can compromise anchor function and safety.

Regularly assessing the exterior of your boat ensures that it remains in optimal condition and can help you identify and address potential issues before they become major problems.

Interior Components That Should Be Checked

- Deck Condition : Begin the interior inspection by carefully examining the deck of your boat. Look for any soft spots or signs of delamination, which can indicate water damage. Pay special attention to areas around fittings, hatches, and the helm, as these are common trouble spots.

- Seating, Upholstery, and Cushions : Check the condition of your boat’s seating, upholstery, and cushions. Look for signs of wear and tear, such as tears, fading, or mold/mildew growth. Damaged upholstery can be both unsightly and uncomfortable, so it’s essential to address any issues promptly.

- Flooring Condition : Inspect the condition of the boat’s flooring, whether it’s carpet, vinyl, or another material. Ensure that it is securely in place and free from tears or damage. Damaged flooring can lead to safety hazards and should be repaired or replaced as needed.

- Cabin and Storage Spaces : If your boat has a cabin or storage spaces, check them for cleanliness and organization. Ensure that everything is securely stowed, and there are no signs of water intrusion or pests.

- Windows and Hatches : Examine all windows and hatches for leaks or damage. Look for any cracked or fogged glass and ensure that seals are intact. Properly functioning windows and hatches are crucial for ventilation and preventing water ingress.

A thorough interior inspection helps maintain the comfort and safety of your boat. Addressing issues like soft spots, damaged upholstery, or leaks promptly can extend the life of your boat and enhance your overall boating experience.

Critical Mechanical Aspects of the Boat

- Engine and Propulsion System : Begin by inspecting the boat’s engine and propulsion system. Check for any signs of leaks, such as oil or coolant, and ensure that all components are in proper working order. Pay attention to unusual noises or vibrations during the inspection.

- Steering and Controls : Test the steering system and controls for responsiveness. Ensure that the steering wheel or tiller moves smoothly and that the throttle and shift controls operate correctly. If you notice any stiffness or difficulty in steering, it may indicate an issue with the steering system that requires attention.

- Electrical Systems : Evaluate the boat’s electrical systems, including the battery’s condition and connections. Check for corrosion on battery terminals and cables, as well as loose connections. Make sure that all electrical components, such as lights, navigation equipment, and accessories, are functioning correctly.

- Bilge Pumps and Float Switches : Inspect the bilge pumps and float switches for functionality. Test the pumps by manually activating them and ensure that the float switches move freely and trigger the pumps when needed. A properly working bilge pump is essential for keeping the boat dry.

- Fuel System : Examine the fuel system thoroughly. Inspect fuel hoses, connections, and fuel filters for any signs of wear, leaks, or damage. Fuel system issues can lead to engine problems and pose safety risks, so it’s crucial to address any concerns promptly.

Checking these mechanical systems as part of your boat inspection helps ensure the reliability and safety of your vessel. Any identified issues should be addressed promptly, whether through maintenance or professional service, to keep your boat in top condition.

Importance of Safety Equipment on Board

- Life Jackets and PFDs : Check the quantity and condition of life jackets and personal flotation devices (PFDs) on board. Ensure that you have enough for all passengers and that they are in good condition, free from tears or damage. Life jackets are a crucial safety item and must be readily accessible.

- Fire Extinguishers : Inspect fire extinguishers for their expiration dates and ensure they are still within their valid periods. Check the pressure gauges to make sure they are in the green zone. It’s essential to have functioning fire extinguishers in case of onboard fires, as they can be life-saving.

- Flares and Signaling Devices : Review the expiration dates of flares and signaling devices, and ensure they are stored in a dry and accessible location. These items are essential for signaling distress in emergency situations, such as getting stranded or encountering rough weather.

- First-Aid Kit : Examine the first-aid kit for completeness and freshness. Check that all essential supplies, such as bandages, antiseptics, and medications, are present and within their use-by dates. A well-maintained first-aid kit can be invaluable for addressing minor injuries while on the water.

- Emergency Locator Beacons and Communication Devices : Test any emergency locator beacons and communication devices, such as VHF radios or satellite phones, to ensure they are in working order. These devices are critical for calling for help in emergencies or communicating with authorities.

Safety equipment is non-negotiable when it comes to boating. Regularly inspecting and maintaining these items ensures that they will function as intended in case of an emergency, contributing to the safety of everyone on board.

Inspection of Navigation and Electronic Components

- GPS and Chartplotter : Verify the functionality of your GPS and chartplotter systems. Ensure they are accurately displaying your boat’s position and have updated charts for your intended route. Test all features, such as waypoint marking and route planning.

- VHF Radio : Check the operation of your VHF radio . Ensure it can both transmit and receive signals effectively. Inspect the antenna for any visible damage or corrosion. A working VHF radio is essential for communication and safety on the water.

- Compass : Verify the accuracy of your boat’s compass. Check that it reads true north and that the fluid level is at the appropriate level. A reliable compass is essential for navigation, especially in case of electronic failures.

- Depth Sounder and Fishfinder : Test the performance of your depth sounder and fishfinder. Ensure they provide accurate readings for water depth and any fish or underwater structures. These systems are valuable for safe navigation and fishing.

- Radar and AIS Systems : If your boat is equipped with radar or AIS (Automatic Identification System), test their functionality. Ensure they are correctly detecting other vessels and potential hazards, especially in low visibility conditions.

Navigation and electronic equipment play a vital role in modern boating. Regularly checking and maintaining these components ensures you have accurate and reliable information for safe navigation and communication while on the water.

Inspection of Anchoring and Mooring Equipment

- Anchors : Inspect your anchors for any signs of damage or corrosion. Ensure that the anchor’s flukes are in good condition and not bent or deformed. Check that the anchor’s shank and stock are secure and not excessively worn.

- Anchor Rode and Chain : Examine your anchor rode (rope) and chain for wear and rust. Look for any fraying, chafing, or signs of weakening in the rope. Check the chain links for any visible signs of rust, and ensure that they are properly attached to the anchor and boat.

- Cleats, Lines, and Fenders : Inspect all cleats, lines (ropes), and fenders. Check for wear, chafing, or fraying in the lines. Ensure that cleats are securely fastened to the boat and not loose. Check fenders for any damage or deflation and ensure they are properly positioned to protect the boat’s hull.

- Windlass or Winch : If your boat is equipped with a windlass or winch for anchor handling, test its operation. Ensure that it can raise and lower the anchor smoothly and that the motor or manual mechanism is functioning correctly.

Properly functioning anchoring and mooring gear is essential for safe and secure boat operation. Regular inspection of these components helps prevent anchor-related mishaps and ensures that your boat remains securely moored when necessary.

Inspection of Plumbing and Sanitation Systems

- Freshwater and Wastewater Tanks : Inspect your freshwater and wastewater tanks. Check for any signs of leaks, especially around tank fittings and connections. Verify the water levels in both tanks to ensure they are neither overfilled nor empty.

- Toilet and Sewage System : If your boat has a marine toilet, check its functionality. Ensure that the toilet flushes properly and that waste is being evacuated into the holding tank as it should. Inspect the holding tank for any signs of leaks or overfilling.

- Freshwater Pump and Plumbing : Test the freshwater pump and associated plumbing for any leaks or irregularities. Ensure that the pump is delivering a consistent flow of freshwater to sinks, faucets, and showers.

- Shower and Washdown Systems : If your boat is equipped with a shower or washdown system, test its operation. Ensure that water flows correctly from the showerhead or washdown hose. Check for any leaks in the system.

Proper functioning plumbing and sanitation systems are crucial for the comfort and well-being of those on board. Regular inspection and maintenance help prevent water-related issues and ensure a clean and hygienic environment.

Additional Items That Should Not Be Overlooked

- Boat Registration and Documentation : Ensure that all necessary boat registration and documentation are up to date and stored securely on board. This includes registration numbers, ownership papers, and any required permits.

- Safety and Navigation Lights : Check all safety and navigation lights for proper functionality. This includes running lights, anchor lights, and any other lights required by maritime regulations . Replace any burnt-out bulbs or damaged fixtures.

- Bilge and Engine Compartment : Keep the bilge and engine compartment clean and free of debris. Check for any oil or fuel leaks that may need attention. Make sure the bilge pump and float switch are operational.

- Trailer Condition (if applicable) : If you use a trailer to transport your boat, inspect the trailer’s condition. Check the tires for wear and proper inflation, inspect the wheel bearings, and ensure the trailer lights are working correctly.

- Dock Lines and Shore Power Connections : Examine dock lines for wear, fraying, or weak spots. Replace any lines showing signs of damage. If you use shore power, check the integrity of shore power cords and connections to prevent electrical issues.

These miscellaneous checks ensure that your boat is in full compliance with regulations, safe to operate, and ready for any situation you may encounter on the water.

Importance of Maintaining Inspection Records

Maintaining accurate records of your boat inspections is a critical aspect of responsible boat ownership. Here’s why it matters:

- Documentation of Inspection Dates : Keep a log of the dates when you performed inspections. This helps you establish a maintenance schedule and ensures that you don’t miss crucial checks.

- Recording Findings : Document your inspection findings in detail. Note any issues, wear and tear, or damage you discover. This written record serves as a reference point for future inspections.

- Maintenance and Repairs : If you perform any maintenance or repairs as a result of your inspection, record what you did, including parts replaced and services performed. This documentation is valuable for warranty claims and can also assist future owners if you decide to sell your boat.

- Resale Value : When it’s time to sell your boat, having a comprehensive maintenance and inspection history can significantly boost its resale value. It demonstrates that you’ve taken good care of the vessel.

- Future Reference : Over time, your boat’s history can become a valuable resource. It helps you track the longevity of various components, anticipate when replacements might be needed, and ensures that your boat remains safe and reliable.

Remember to keep these records in a safe and accessible place, and consider digital or cloud-based options for added security. This practice not only safeguards your investment but also contributes to a safer and more enjoyable boating experience.

Conclusion – Boat Inspection Checklist

In conclusion, the boat inspection checklist presented here offers a comprehensive and systematic approach to ensuring the safety, reliability, and longevity of your vessel. By diligently following this checklist, boat owners can:

- Ensure Safety : Regular inspections are a crucial component of safe boating. Identifying and addressing issues early on can prevent accidents and potential hazards.

- Prevent Issues : Proactive maintenance, as facilitated by this checklist, helps prevent problems before they become major repairs. This can save both time and money.

- Extend Lifespan : A well-maintained boat enjoys a longer and more productive life. Careful inspections and timely maintenance contribute significantly to your boat’s longevity.