Sailboat Bottom Paint: 10 Best Paints

Last Updated by

Daniel Wade

June 15, 2022

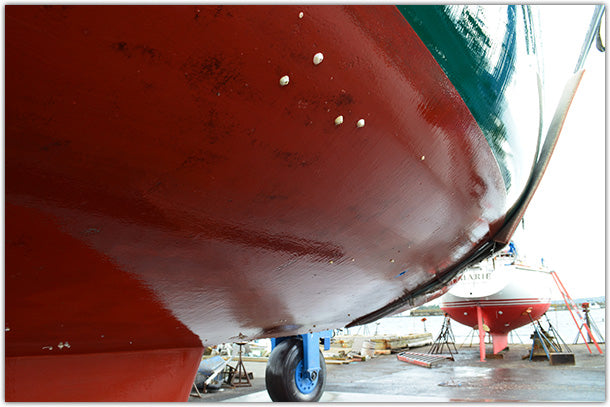

If you leave your boat without protection, it's beyond question that it will start attracting several marine organisms such as slime, algae, mussels, barnacle, and seaweed. This will cover the bottom of your sailboat and may negatively affect your boat's speed and fuel efficiency.

This is exactly why you need to apply the best sailboat bottom paint on your boat.

The freedom that sailing and being off land gives you are immense and almost unmatched.

But do you know that having multiple organisms such as algae, slime, barnacle, seaweed, and mussels grow on your boat can throw everything out on the wind and leave you with a very unreliable boat?

These pesky hangers will put a huge dent in your boat's speed, its movement, fuel efficiency, and overall aesthetic.

That's why you need the best sailboat bottom paint to greatly minimize any damage that might be caused to your boat's hull by marine biological growth.

Also known as antifouling paint, bottom paint is essentially a paint or coating that's specifically designed with elements that prevent various marine organisms such as algae, seaweed, barnacles, slime, and mussels from attaching themselves to your boat's hull or any other part of the boat that's below the waterline.

One of the most important elements of bottom paint is the inclusion of a biocide and copper is the most common. This may, however, depend on the type of boat that you have, how, and where you always use it.

But because there's an ocean of bottom paints out there on the market, choosing the best sailboat bottom paint can be an overwhelming task for most of us.

Fortunately, you can always count on us to make it a lot easier for you. We've gone through many bottom paints and we do not doubt that we've selected the most effective, reliable, and best sailboat bottom paint.

Our unbiased selections will not only match your needs and budget but will be available in a variety of colors to complement and augment your boat's visual appeal.

Table of contents

What to Consider when Purchasing Sailboat Bottom Paint

If you're on the market for the best sailboat bottom paint, it's crucial to go for top quality; something that will offer efficiency, top speed, and excellent performance for your sailboat. With that in mind, here are a few things to consider before spending your hard-earned money on bottom paint.

Your Sailing Location

Where are you planning to sail? Is it on a freshwater body or in a saltwater location? This is essential in helping you determine whether to go for a bottom paint that's meant for saltwater, freshwater, or both. It's generally recommended that you go for a bottom paint that will serve you perfectly well in both freshwater and saltwater. This gives you the versatility of sailing anywhere without worrying about marine organisms damaging your boat's hull.

Launch Time and Recoat Time

It's important to keep in mind that bottom paint products have specific launch time limits. The idea here is to ensure that you launch it within the required timeframe and ensure that recoating is done as required. You should, therefore, choose a bottom paint that offers a lengthy launch and recoat time while offering durable protection for your vessel is the right thing to do.

Type of Boat

You should determine whether your boat is made of wood, fiberglass, or aluminum and go for bottom paint that's suitable for that particular surface. Many bottom paints work perfectly with fiberglass but some work great with aluminum or wooden surfaces.

The Fouling Condition

Having a deeper idea of the type of fouling that you might deal with can be crucial when buying the right bottom paint for you. Whether you're dealing with slime, algae, mussel, or any other type of marine organism, knowing the type of fouling you're dealing with will make it a lot easier to pick the best sailboat bottom paint for your vessel.

Best Sailboat Bottom Paint

Rust-oleum marine flat boat bottom antifouling paint.

As one of the most respected brand names in the bottom paint industry, Rust-Oleum is known for producing some of the best sailboat bottom paint and the Marine Flat Boat Bottom Antifouling Paint is one of them. This bottom pain is designed to be suitable for various conditions (both freshwater and saltwater) and is designed with moderate copper that works great if you are environment-conscious.

This bottom paint does an excellent job of offering a protective coating to ensure that your boat is free of all sorts of unwanted marine organisms. You'll love this paint because it is thick and spreads so easily and will not be a problem even if you're a beginner. This bottom paint offers top-notch antifouling properties and is very easy to apply as long as you use a soft brush and mix it carefully. This is a great bottom paint choice that will offer a sleek multi-season finish and ensure that your boat's hull is always awesome and in great condition.

- Easy and simple to apply

- Great for both freshwater and saltwater

- Offers gentle fouling conditions

- Excellent in antifouling

- Offer a sleek and awesome finish

- Quite expensive

- Has a very strong smell that can cause headache

Interlux Fiberglass Bottomkote Antifouling Paint

This is another great brand that is considered as one of the best bottom paint in the sailing world. Even though it's a bit pricey, it offers great features that will ensure that your boat remains in tip-top shape. It is an excellent option if you're looking for a sailboat bottom paint that brings to the fore a unique dual resin approach.

This is a very reliable bottom paint that will not only prevent your boat's hull from the effect of marine organisms but also prevent premature deterioration. It offers an awesome polishing action and is perfecting if you want to discard unnecessary paint buildup. This bottom paint is also very economical and a small quantity will cover a considerable surface area of your boat's bottom.

This is, without a doubt, a superb buy in terms of its practicality and economical nature. It is excellently formulated to prevent marine organisms from damaging your boat and also to ensure that premature wear and tear doesn't exist in your vocabulary.

- It's formulated with a unique dual resin approach to prevent premature wear and tear

- It prevents early decline

- It prevents unnecessary paint buildup

- Great for ensuring that your boat is fuel effective

- Great for all conditions (both freshwater and saltwater)

- It's expensive

- The quantity and size can be misleading

TotalBoat JD Select Bottom Paint

As one of the few bottom paints that's formulated with low Volatile Organic Compounds (VOC), this bottom paint is one of the most cost-effective on this list. With one gallon, you can easily cover about 400 square feet and the application is a breeze since it's even much easier to clean up.

When you purchase this bottom paint, the package will come complete with a pair of latex gloves, a wooden stir stick, an abrasive pad, a metal tray kit, a paint suit, a roller, a painter's tape, and many more. The inclusion of all these accessories makes it a quite cost-effective purchase.

Again, this is one of the most durable bottom paints. Apply it on your boat's hull and you're guaranteed that it will offer excellent protection for the next 18 months. On the downside, this paint is too thick and you'll have to buy an excellent thinner for it to work perfectly.

Nonetheless, this is an ablative bottom paint that is easy to apply and does an excellent job of protecting your boat's bottom for close to two years.

- Perfect for all conditions

- Easy to apply and clean up

- Can improve your boat's speed and fuel efficiency

- Comes with all accessories required for the paint job

- It's one of the best water-based bottom paint products in the industry

- It contains low VOC

- You'll need a top-quality thinner for it to work perfectly

Aquaguard Water-based Antifouling Bottom Paint

An excellent choice for both wooden and fiberglass boats, this is the most perfect bottom point for saltwater conditions. This is a water-based bottom paint that's very easy to apply and clean up (using soap and water) and is formulated with an ablative action that makes it superb for preventing any marine organism that may negatively affect your boat.

This is a bottom paint that is EPA-approved and surpasses the set VOC standards. It has an extended shelf life and offers durable protection for your sailboat. It doesn't contain toxic fumes and is great even for novices. Its drying time is also excellent, so you won't wait for far too long to get your boat out there on the water.

- Excellent for saltwater conditions

- Application and cleaning is very easy

- It's approved by the US EPA

- You don't have to use a primer

- The color selection is limited

- A bit pricey

Pettit Hydrocoat

This is another water-based bottom paint that offers outstanding ablative properties that will protect your boat from marine organisms throughout the seasons. It offers good value for money and is easy to apply and clean up with just water and soap.

We're talking about a bottom paint product that will protect your boat's hull for months on end. You also do not need a full tank of the paint to complete the job. With just a single gallon, you can be sure to complete an area as big as 430 square feet.

This is also one of the few bottom paints that can perfectly prevent your boat from damage when being trailered, launched, or beached. More importantly, it's not irritating to the nose and eyes because it has low VOC.

- It will dry in 3 hours

- It's easy to apply and clean up

- It offers multi-season protection

- It's not irritating to the eyes and nose

- It's quite economical

- May not be the best in antifouling

- You have to apply at least two coats

SEA HAWK PAINTS Aluminum Boat Paint

One of the best aluminum boat paints in the market, this bottom paint is formulated to offer quick-dry corrosion-blocking, high-solid features. This bottom paint is specifically manufactured to be used in aluminum boats and doesn't require the addition of any primer.

While it doesn't have an antifouling feature, it stands out and can be used both below and above the waterline as it is risk-free and free or chromate. It is also formulated to offer a unique dual resin approach and can be used both as paint and a primer at the same time.

This is a great paint for both freshwater and saltwater conditions and can be applied as a primer or topcoat on a fiberglass boat. This is an excellent sailboat boat bottom paint that's worth every coin as it is practical, versatile, and can combat both rusting and lifting.

- The application and cleanup process is easy

- Great for both freshwater and saltwater conditions

- It doesn't require a primer

- Can be used as primer or topcoat in fiberglass boats

- Can prevent rusting and lifting

- It has quick-dry and anti-corrosion features

- Can produce deadly fumes

TotalBoat Spartan Boat Bottom Paint

If you've been looking for a practical, reliable, and cost-effecting bottom paint that will offer durable performance and protection, the Spartan Boat Bottom Paint. Perfect for both freshwater and saltwater, it can be perfect for protecting your boat and ensuring that it is fuel-efficient and reliable.

This bottom paint is formulated with advanced copolymer ablative to ensure that it doesn't deteriorate instantly. This is a very dependable bottom paint that will serve you perfectly throughout the year and will ensure that your boat easily defies fouling while reducing unnecessary buildup and sanding on your boat.

This is a very adaptable bottom paint that not only offers great value for money but is very easy to apply. More importantly, it is very durable and will protect your vessel for at least 12 months on any type of water.

- Great for all types of water

- It offers a very durable protection

- Available in a wide variety of color selection

- Offer a visually appealing abrasion-proof finish

- The included accessories aren't up to the right quality

To this end, we must put a lot of emphasis on the importance of having the right bottom paint for your boat. In addition to being an antifouling agent, bottom paint will significantly increase the fuel efficiency of your boat and ensure that it performs optimally at all times. Of course, you do not want to diminish your sailing escapades or have your nice and beautiful vessel damaged by marine organisms just because you didn't apply the right sailboat bottom paint. If you're unsure how to proceed, here's how to paint a sailboat.

Related Articles

I've personally had thousands of questions about sailing and sailboats over the years. As I learn and experience sailing, and the community, I share the answers that work and make sense to me, here on Life of Sailing.

by this author

Repairs and Maintenance

Sailboat Upgrades

Most Recent

What Does "Sailing By The Lee" Mean?

October 3, 2023

The Best Sailing Schools And Programs: Reviews & Ratings

September 26, 2023

Important Legal Info

Lifeofsailing.com is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to Amazon. This site also participates in other affiliate programs and is compensated for referring traffic and business to these companies.

Similar Posts

How To Choose The Right Sailing Instructor

August 16, 2023

Cost To Sail Around The World

May 16, 2023

Small Sailboat Sizes: A Complete Guide

October 30, 2022

Popular Posts

Best Liveaboard Catamaran Sailboats

December 28, 2023

Can a Novice Sail Around the World?

Elizabeth O'Malley

4 Best Electric Outboard Motors

How Long Did It Take The Vikings To Sail To England?

10 Best Sailboat Brands (And Why)

December 20, 2023

7 Best Places To Liveaboard A Sailboat

Get the best sailing content.

Top Rated Posts

Lifeofsailing.com is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to Amazon. This site also participates in other affiliate programs and is compensated for referring traffic and business to these companies. (866) 342-SAIL

© 2024 Life of Sailing Email: [email protected] Address: 11816 Inwood Rd #3024 Dallas, TX 75244 Disclaimer Privacy Policy

The Fastest Boat Bottom Paints: Antifouling for Speed

Whether you're racing your boat or cruising casually, everyone wants to sail faster. Is there a bottom paint that will make your boat sail faster? And is it right for you?

What are The Fastest Boat Bottom Paints? The fastest bottom paints are vinyl or Teflon based hard paints, which can be wet sanded and burnished to a smooth finish .

Maintaining a fast, racing finish with these paints requires more maintenance than a hard copolymer or a softer ablative paint. It is more maintenance, but it can make a big difference in boat speed.

On this page:

What slows you down, bottom preparation is everything, maintaining the finish, alternatives to hard and burnished, how much faster is it, what are your goals, racing vs. cruising.

In a word: friction. Friction causes turbulence and drag

Without requiring a degree in Computational Fluid Dynamics to explain it, a rough bottom is slower. More friction is slower - think about rubbing your hand across a carpeted floor versus a glass table top with a little oil spilled on it. Which is easier? Now imagine you're playing with a toy boat on either surface. If you push the boat, which one will be easier to push? Which might even keep sliding a little if you let it go?

Getting more into the science (still without the degree!), when fluids move over a surface there is a "boundary layer," the layer of fluid closest to the surface skin. When a hard surface moves through a liquid, molecules of the liquid get dragged along with it. This increases "skin friction" and causes drag. The faster something moves, the more drag.

If the flow of molecules in the boundary layer is "laminar", it is evenly spread and more calm. A "turbulent" boundary layer pulls more water with it and causes more friction and drag. A smooth bottom helps maintain laminar flow and reduce turbulence and drag as the boat speeds up.

These forces can be considerable if a boat bottom is not a fair surface, and the effect is more pronounced at higher boat speeds.

Given the power provided from your sails is constant, a boat with less drag will move through the water faster.

Spraying a layer of VC Offshore or Baltoplate on your boat will not make it instantly faster. To get the full benefit of a hard, fast bottom paint job the surface bottom must be prepared with care.

- Old incompatible bottom paint must be stripped. You can't put a Teflon based paint over an ablative or copolymer paint. It won't stay on.

- The bottom should be "faired." The aim is to create a smooth, curved surface with no bumps, dips or ripples. This is labor intensive and requires expertise and a keen eye to fair a hull.

- The bottom should be sanded smooth after fairing and before painting. Even if an orange is round and fair, if you spray paint it you will not end up with a smooth surface. You must start with a smooth surface.

- For a fast finish, spraying gives an even, smoother coating and reduces the amount of sanding time. Rolling hard bottom paint makes little sense because of the increased work from the rough paint application.

- Sanding and wet sanding is a must. Sprayed paint will still feel rough to the touch. For a fast finish sanding and wet sanding with up to 400 grit sandpaper will get results.

- Burnishing is a step even farther than wet sanding, and can give a mirror finish to a well prepared bottom.

Hard bottom paints designed for racing are not as effective at preventing grown as softer ablative paints or copolymers. They don't hold as much active antifouling, and it doesn't leach out of the paint or get refreshed since the paint doesn't slough off. And wet sanding and burnishing both remove some surface active ingredients.

In high growth areas, a racing finish with require constant maintenance and cleaning. When I raced my last boat, I had a diver come every week to clean the bottom and we dove on the boat ourselves at major regattas. You won't get hard growth quickly, but you will get slime buildup in very little time which can slow you.

You may not get two seasons from a coat of racing paint. If you don't, you'll want to wet sand it before the start of the season to ensure everything is smooth and ready again. The good news is that a properly prepared bottom is easy to re-spray and sand back to a good finish compared to the first time you do it.

What if you don't dive, can't clean your boat regularly, or don't want to pay a diver? Maybe you just want to go faster but aren't a speed-mad racer looking for every 1/10th of a knot speed extra?

Dry sailing for smaller boats is very popular. Fair the bottom and leave it unpainted or put on an underwater epoxy paint. As long as you don't store the boat in the water for more than a couple of days during a regatta there shouldn't be any growth. Most dinghies are dry sailed. Many smaller boats kept at clubs or marinas with a crane have this option, though there may be a cost to haul and launch.

If you stay in the water, a good choice is a hard copolymer paint. These are often referred to as "self polishing," as they smooth themselves with use as the paint sloughs off. Many of these are quite hard and can be carefully sanded to a smooth finish. Since they’re softer, you don’t want to sand through the paint. With proper preparation before painting, a sprayed paint job, and a little sanding, your bottom can be almost as fast as the high maintenance race boats.

Even without the sanding, a good bottom preparation before painting can give you more speed on passages. These paints are popular with long distance cruisers and people who use their boats frequently. You'll lose a little edge if you're racing, but you won't put yourself at the back of the fleet with it.

"What are you getting for your money" is a common question when preparing a boat for racing. The faster bottom and the newest sails won't win races for you if your crew can't tack or gybe and you can't spot wind shifts. You can lose the entire advantage of that quarter knot speed increase with a blown tack or a missed shift.

From personal experience, replacing a rough, coarse, orange-peel looking bottom with a polished and burnished bottom made a big difference. Both in my boat speed, and my wallet. It was expensive to do and expensive to maintain. But the boat was faster, and we were racing competitive regional events. The difference was most noticeable at low speeds and in light air.

There is not a lot of empirical data about how much faster a burnished Teflon bottom is over a well prepared copolymer paint. So the answer is "yes, it's faster," but with your boat, your budget, and your application there’s no way to predict that you may be 5% or 10% or half a knot faster.

To the casual club racer or cruiser, is it worth the time and money to prepare and maintain the fastest of possible finishes? It may not be; that's a question that only you can answer.

The best choice for a fast bottom comes down to you, your boat, and how you will use it.

- Are you a racer? If yes, is it weeknight club racing, or are you racing at higher level regional events against serious racers?

- If you cruise, how much maintenance are you willing to do to keep every extra fraction of a knot of speed?

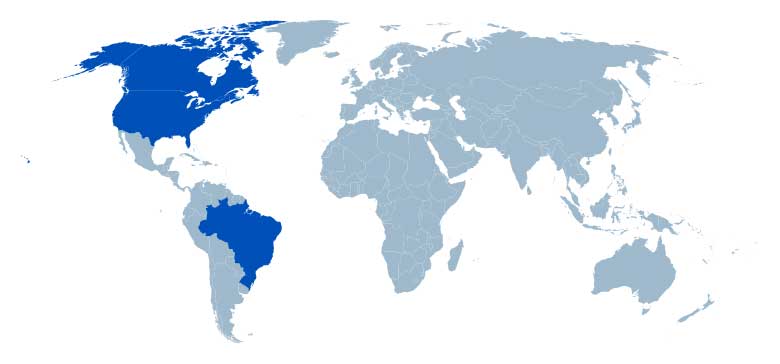

- Where do you sail? Some areas have more aggressive growth than others. A sailor in the Great Lakes may get away with a hard bottom paint with less work than a New England coastal racer or a cruiser in the Caribbean.

- What is your budget for bottom preparation and maintenance? Are you willing and able to do some yourself?

- What us the current condition of your bottom? How ready is it for a top quality refinishing?

You will find very few non-racers who take the time and effort to apply the fastest bottom paints. The cost/benefit/effort analysis doesn't show a reasonable payback for what you get.

Most sailors aren't taking their boats to world-class regatta venues, they're taking off for weekends and vacations and maybe doing the club series on Wednesday nights or the annual regatta. Most of those boats are not going through the expense and effort for a competitive racing finish.

On the other hand, if you're racing in a competitive one-design fleet at New York Yacht Club Race Week or the San Diego NOOD Regatta, you can bet almost every boat in your fleet will have a smooth, wet sanded finish.

Leave a comment

You may also like, do i need to antifoul (bottom paint) my boat - sometimes.

Any time you buy a new boat, you get a work list as long as your arm. Bottom paint is expensive, toxic, and can be difficult to apply. It's an easy task to want to …

41 Sailboat Cruising Essentials for Long Trips

How to Calculate Outboard Motor Size for Sailboats

- Forum Listing

- Marketplace

- Advanced Search

- All Topics Sailing

- Living Aboard

- SailNet is a forum community dedicated to Sailing enthusiasts. Come join the discussion about sailing, modifications, classifieds, troubleshooting, repairs, reviews, maintenance, and more!

whats the best bottom paint for racing

- Add to quote

I am stripping all of the 27 yrs of bottompaint off and will be applying several coats of new...except this time i want to put a faster bottom on her and was curious to what yall suggest?? lancer 36

It depends... do you keep the boat in the water or not?

yes saltwater,NC

Racers like hard paints like VC17 or Baltoplate. Note that the bottom paint wont be any faster than the quality of the bottom prep underneath the paint. if you you don't spend 5-10 full days fairing the bottom with microballoon filler and a long board, don't bother with a hard bottom paint, just roll on some ablative stuff and go sailing...more slowly.

Bottom paints tend to behave differenty in different areas. Ask the racers in your area what they use and how they like. Your best bet will probably be to go with thier consensus. I use Baltoplate and like it. However, note that none of these paints are going to be as effective as the cruising alternatives at keeping growth off; you will have to regularly clean your bottom.

you will have to regularly clean your bottom. Click to expand...

Mikelivingstone said: At Jason, I am considering switching from ablative bottom paint to try to better performance. But would like to ask how often does it have to be cleaned underwater? Mike Click to expand...

Yes, certainly before any major race I'll either get in and scrub or get a diver. In the meantime, I use a Dri-Diver ( DRI-DIVER - Boat Hull Cleaner, Remove hull growth from the dock ) to keep the hull free of too much growth accumulation. I'll scrub with the Dri Diver once or twice a month and dive (or pay a diver if it's cold) 7 or 8 times a year.

NOLA..thanks for the link.. we use an old fishing net with a line tied on both ends..tyhe ropes go up the and up the hull on each side to a person on each side standing on the deck then one pulls the other one lets go a little ,and both move back and forth like a saw, and walk back

Thanks for d advice Jason and Alex. -Jason can you operate the dri diver from your own boat? Also the rope and net method can be done up to the keel only? Will any of the methods clean the keel? I am not a serious racer but appreciate good performance. Thanks Mike

Mike, the problem is it does not clean the keel...you really need to dive or wash with pressure washer

Thanks, I'm thinking of investing in a diving course anyway.

Just take the boat to Gozo...and do a little dive..lazy bastardo.....

Alex, if no one has said it to you I will. You have to many animals in your life. What's up with Penguin bottom paint.

did you ever talk to the guys at Enemalta? I miss Malta so much...left wonderfull frineds there...and I remeber going to to a cliff (where they found the great white), and eat Hobbz bis zeit.(mispelled)

Mikelivingstone said: Still hope u make the Middle sea race next year. Click to expand...

Why do you need a radar for the middle sea race?

Not for the race....to get there from Portugal...especially going into Gibraltar.. Once there it comes off..

chucklesR said: Do you have to dive if your draft is only 18 inches? I wipe my bottom with a sponge while standing next to the boat. Guys, don't go there, keep the thread on topic Click to expand...

Understand, It can sit in my garage for the race if you like....and any other stuff you want to unload during the race.

The method Gui proposes works well and it does clean the keel. In fact, there's a commercial product that does the same thing (EZ Diver, or something). The negative is that it takes two people and is a bit cumbersome. I like the Dri Diver because I can do it myself or, if we're prepping the boat to race, hand it off to a newbie crew who may not know how to rig the boat. As for the keel issue - for me the keel does not accumulate growth nearly as quickly as hull nearer the waterline and along the rudder. I can clean my transom hung rudder with the deck brush and the rest of the hull with the Dri Diver. For the keel, it takes getting in the water, but a scrub every six weeks or so keeps it pretty slick. I can clean my keel by free diving. Gui's Penguin paint may be a good paint. I've seen videos of Penguins and it looks like they move through the water very well. I had no idea Gui painted them though... Seriously - bottom paint behaves differently in different regions, so I'll say again, go with what the majority of the successful racers in your area are using.

- ?

- 176.1K members

Top Contributors this Month

SPEEDCOAT-49

The very best in high performance boat bottom coatings.

Optimize Speed! Use Less Fuel!

Resist pond scum and fouling, and super easy to clean .

Specifically, what is Speedcoat-49? It is a permanent, non-ablative, hard boat bottom coating that utilizes unique Wearlon chemistry to achieve hydrophobicity, non-stick and anti-friction properties.

Speedcoat-49 began as a water-drag-reducing hull coating for power boat racers, but now it is highly coveted by all sorts of boaters that not only want to go faster, but also use less fuel, and provide an easy to clean, non-stick surface against pond slime, algae, and fouling. But perhaps most crucial of all, it is a non-ablative bottom coating!

This high performance hull coating will help every kind of boat perform better, and in many different ways. Boats such as pontoon boats, speed boats, and all sporting and leisure boats, will see benefit in these six significant ways.

Six Huge Reasons why Speedcoat-49 is the best bottom coating for your boat:

1.) Lowers water drag , which means increased speeds and fuel savings:

Speedcoat-49 is used by powerboat racing teams to achieve optimal speeds, win races, and acquire championships. As with many high quality speed coatings, SC-49 is hydrophobic.

However there are many misconceptions about hydrophobicity. Many think that with improved hydrophobicity comes improved water drag, and faster speeds. NOT TRUE . Hydrophobicity helps because the surface tension causes water to bead up. But what really matters is how fast those water beads want to travel all along the surface as it is shedding off. Often times, beads of water will actually want to cling. The U.S. Navy tested numerous hydrophobic and water drag resistant coatings for various marine applications. Not only have they chosen SC-49 for many of their naval vessels, they also coat their battleship radomes because SC-49 has excellent water shedding properties, and that is crucial with this type of equipment.

Movement of water along the surface and water drag resistance is the key to speed. Speedcoat-49 is a unique coating with unique chemistry. Boat racers understand this. That’s why Wearlon SC-49 is being used by boat racers at the highest levels. Some of these racers, like these Unlimited Hydroplaners, can reach speeds of over 200 MPH.

But obviously, most boaters are not racers. Sporting and leisure boaters can also benefit from increased performance. Even smaller (engined) leisure boaters are recording higher speeds , and decreased fuel consumption.

-(see the “Speed Data” tab on the menu bar for more technical info on speed and drag reduction).

“The acceleration is incredible – you gotta hang on. I can beat anybody on our lake. Went from 77/78 MPH to 81 MPH ” – Al Craig, 300 HP Sea Doo

2.) Foul & Slime Resistant and Easy to Clean :

When it comes to the need for foul resistance, ablative paints are the go-to. And yes, most ablative paints get the job done in terms of anti-fouling. But, in doing so it leaches toxic metals into our waters. This unfortunate reality has become a necessary evil in dealing with the extreme fouling problems salt water has to offer. But, SC-49 has proven itself as an excellent foul-resistant coating in fresh water. Zebra mussels, algae, and all the types of fouling encountered in fresh water are no match for SC-49. So why use ablative in fresh water? Why poison our freshwater with this stuff when you don’t have to? Not to mention, ablatives still stain, dull out, deteriorate, and hardly last a season. Speedcoat-49 is so slick and non-stick, fouling organisms have a difficult time sticking to it. In most cases, your hull will become easy to clean with a hose and a soft nylon brush and maintain a vibrant appearance and functionality.

From David Morrill in NH, here is a typical example of a Speedcoat-49 experience:

And here is Speedcoat-49 under a worse-case-scenario:

“ Lake Hopping ” has become more difficult due to ever increasing regulations forcing boaters to clean their hulls before and after every launch. SC-49 makes this much easier. Easy clean, means saving time and money. It also means deterring those horrible-looking scum lines.

-(See the “Anti-Fouling Data” tab on the menu bar for more technical info).

” I was experiencing significant hull cleaning problems from leaving the boat in the water for the summer at Lake Erie. I found the product did a excellent job resisting the growth of algae/crud from the lake. Most of the growth came off while the boat was running (probably due to the slickness of the coating).” – Ken Huckaby, 20′ Crestliner

3.) Speedcoat-49 is a permanent, hard, non-ablative coating :

Today’s boaters largely go with one of four options for bottom coatings. They are: seasonal ablatives, solvent-based permanent, waterbased permanent, and gel coat.

Solvent and water-based permanent paints are primarily meant to be protective and durable, but don’t offer much in terms of foul resistance, cleanability, or anything else.

Gel coats are the shiny fiber enriched epoxy/polyester finish that looks sharp and glossy. For that reason, many do not want to put a coating over this. But after a short period of time in water, gel coats and protective coatings alike, pick up discoloration, algae, fouling, and waterline stains, all of which are very difficult to clean, and slow down the boat. Extensive and expensive acid-etch cleaning usually becomes necessary at this point.

And then there are ablatives. If you are using an ablative anti-fouling bottom paint on your freshwater boat, you are releasing poison into our waterways , and into the fish you are trying to catch and eat. Speedcoat-49 is eco-friendly, and is perfectly safe for our water systems and aquatic life.

Today, most of all anti-fouling bottom paints are ablative. Ablatives are self-sacrificial. These paints are actually designed to deteriorate, to be self-sacrificial, constantly leaching toxic biocides and heavy metals out until the paint fully deteriorates.

These toxic leaching bottom paints are a tremendous scourge on aquatic life. It is already an unfortunate necessity that such coatings are being used in our oceans. They are a necessary evil in salt water in combating barnacles and such, but to use such toxic coatings in our freshwater rivers and lakes,… it really is unconscionable and unnecessary! But that is happening. Also, using ablatives means constant re-application which makes it a cash cow for paint manufacturers, retail boat stores, and marinas. It has become real “racket”.

Speedcoat-49 does not leach harmful toxins into the water as it’s method of action to combat fouling. Instead, Speedcoat-49 works on the principle that a super slick and non-stick surface is very difficult for algae, pond scum, zebra and quagga mussels to get adhesion to.

And unlike ablatives, Speedcoat-49 lasts for many seasons without any need for recoat. This means big savings on those high costs marinas charge for seasonal cleaning and re-application.

Speedcoat-49 offers the performance of top-notch speedcoats, the durability of permanent protective coatings, the fresh water foul-resistance of ablatives, and it’s easy cleanability is unsurpassed.

“ It definitely helps” “on there for 3 seasons with no issues” “definitely smoother and slicker” “durable” – John Culver, 1L Mod Hydro

4.) Speedcoat-49 is safe and easy to apply and touch up , (And no primer coat needed) :

Many boat bottom paints require primer coats because the top coat has weak adhesion to aluminum and other surfaces. SC-49 adheres great to just about any surface type. And it is durable and long-lasting, so an extra primer coat is not needed.

Speedcoat-49 is also non hazardous and water based. It is safe and easy to apply. It can be applied yourself with a standard paint roller or by spray.

With toxic ablative coatings, and solvent based high VOC permanent coatings, you either have to spend big $ on pro marina applicators, or try doing it yourself. But read what a Senior Admiral Club member on the popular “The Hull Truth” website, warns about trying to apply a standard ablative and solvent based paint yourself. Here are a few excerpts from his post:

“A bottom job ain’t what it used to be. I used to do it myself, but no longer will even consider it. Ablative Bottom paints are hazardous materials and constitute hazardous waste. Fumes from bottom paints are poisonous.”

“ So here goes: You will need to get into a proper full paint suit and wear a ventilator. Nothing on you should be exposed. Scrape away until the all loose paint is removed, scuffed, or ready to be painted over. Clean up debris. Remove all old zincs. “

“ Paint on first coat in a color DIFFERENT from desired color. After first coat dries, paint with desired color. This way, when you see the not desired color, you know that you need another bottom job. You may want to have air pumped into a face shield as bottom paint fumes are very toxic.”

“ There is whole lot more to do here. it took me 4 weekends. Presently, the going rate is $26 per foot plus materials. To me, that’s a deal.” -posted by ‘High Interest’ (Senior Admiral Club member on The Hull Truth Forum)

SC-49 is a waterbased and relatively low VOC coating. And from a hazard standpoint, it is much like a typical latex house paint used in a home.

With Speedcoat-49, there is no more constant reapplications. And compared to the nightmare of trying to coat your boat yourself with ablatives, and other solvent-based permanent coats, SC-49 is safe, easy and the job is done in hours, not weeks .

Lastly, SC-49 is permanent and durable. But if somehow there is damage, touching up is a cinch. It has great adhesion to aluminum, fiberglass, gel coat, and to itself, and will last for many seasons.

5.) Specifically engineered by Plastic Maritime Corp, a long-standing and distinguished company.

For over three decades PMC, makers of Wearlon Industrial Coatings , has been on the technological forefront within the waterbased industrial coatings class for achieving optimal results in areas of nonstick, anti-friction, hydrophobics, and water drag resistance. Wearlon chemistry is unique. There is no other coating like it; it is a patented technology.

PMC has also introduced its shallow-water boat bottom coating line (for sportsmen) called Wetlander . This extra tough and super slick bottom coating has quickly become a top seller for jon boaters, drift boaters, mud boaters, jet boaters, and airboaters.

6.) Speedcoat-49 outperforms the competition:

High performance racers, the US Navy and all those that put performance first, choose SC-49. Just read what our customers have to say on our Testimonials page.

The benefits of SPEEDCOAT-49 are now being realized on every variety of boats,… lake cruisers, pontoons, catamarans, jet boats, bass boats, trolling rigs, sailboats, race boats, jet skis, hydroplanes, sprint boats, ski boats, drag boats and even kayaks. Speedcoat-49 will get you moving faster through the water, decrease your fuel consumption, and keep your hull clean, and keep our lakes, rivers and oceans clean.

“It’s the best thing I ever did for my boat” “after 450 hours of boating and trailering it still looks brand new. It’s the best coating in the world” -Dave Jensen, Tritoon with 250 HP

Sponsored boat racers, university researchers, and the United States Navy, have all done extensive testing with Speedcoat-49.

Just read what all of our customers have to say about SC-49 performance .

The Racers : The smaller, stock runabout racers say they get 1/2 to 1.0 “extra” MPH while using Speedcoat-49, compared to other bottom coatings they have tried. The guys we get the most data from race in stock classes that can reach speeds anywhere from 80 to 200 MPH, so a little extra means a lot.

The Universities : SPEEDCOAT-49 has been independently tested by universities and research labs all over the world. The University of Buffalo offered volumes of data showing the decreases in water-drag

The US Navy: The US Navy, through it’s various subcontractors, have been applying our Speedcoat-49 coating to key areas of nuclear submarines and battleships for over a decade. But, they don’t share data.

Application Product Data : SPEEDCOAT-49 can be applied by anyone. You do not need a professional applicator, special materials, licenses, or a Haz Mat suit to apply it.

- SPEEDCOAT-49 is non-ablative and remains effective for years.

- Contains no heavy metals or biocides.

- Suitable for both fresh and saltwater; however, this is NOT a barnacle-proof coating in saltwater.

- Water-based formula is stable, easy to apply, and will not harm the environment.

- SPEEDCOAT-49 is applied directly to aluminum with no primer; two complete coats is sufficient.

- SPEEDCOAT-49 is applied directly to fiberglass and gelcoat with no primer; two complete coats is sufficient.

Free samples are available!

Just email your address to [email protected] , with the subject line “speedcoat-49 test panel”, and we will send you a pre-coated panel to test., share this:, 28 comments on “ speedcoat-49 ”.

I have a 14’ aluminum boat that is oxidized and showing holes now. I am concerned about wire brushing since I feel lots more holes will show up. Will your coatings take care of this issue ?

Hi William,

If your aluminum is that thin, and that “holey”, and that oxidized…. well, you know it might be too late for the ol’ girl. I haven’t seen your boat, so I cannot comment directly, but -49 is a two-part epoxy, so it can help seal up some minor pinholes holes and prevent further oxidation damage. However, I would not expect it to fill in and/or cover large holes. There should not be a need to for an aggressive wire brush; we can get good adhesion results with just 100-150 grit sandpaper and an acetone wipe. Please feel free to call me directly at 518-469-3612 so we can go over your specific situation in more detail.

Can your product be applied over existing paint or does the bottom need to be sandblasted to gelcoat before applying your product please let me know thank you

Yes, Speedcoat-49 can be applied over an existing paint, as long as that existing paint is in very good shape, and is not an ablative, or sacrificial “bottom paint”. Your best bet would be to give me a call at (518) 469-3612, and I will ask you a series of questions. From there, we can both decide what your best move is.

I have a 26’ Triton bay boat. Is there anyone you would recommend for the application of speed coat 49?

Any local marina, boat yard, or boat repair shop will have no problem applying Speedcoat-49. It is safer and easier to apply than most of the other coatings they are used to applying.

i have a aluminum boat that i race in a tiller handle class will this product help me on the days when the water is slick slowing me down

Stock racers are the ones who like Speedcoat-49 the best, as it gives them a bit of an edge. If you are currently racing with a bare aluminum hull, I think you will feel a huge difference…

Hi where can I purchase your product

Hi Salvatore,

You order it from us, the manufacturer, and we ship it directly to your door. You can order from Speedcoat49.com, or you can call me at 518-469-3612.

Wanting something for my 1987 fiberglass bass boat that I have in a freshwater river. Always seems to have some kind of scum line from all the vegetation that happens to be in the water. Was wondering a couple of things. Does this change how the handling of the boat by being so slick surface. And does this come in just colors or is there a clear for the custom striping of metallic red that I have on the side of my boat.

Speedcoat-49 is perfect for reducing that scum line and making it much easier to wipe away. The handling will not be effected too much if you have any kind of lower unit in the water, longitudinal ribs in the water, or even a keel. Some jet boats with super round bellies (and airboats) will swing wide in a turn, but those guys are used to it, and like it! Only colors; no clear coat version.

I have an aluminum boat that I use in the salt water. When not in use it is in dry storage. Once I have been using the boat after about 3 weeks a moss/algae growth starts appearing on the sides below the water line. After about 5 weeks in the water small barnacles start showing up on the bottom. I usually don’t keep the boat in the water for over six weeks before I have in out and back on dry dock. I have to clean the and sides that were below the waterline. If I take it out of the salt water after just 3 weeks I usually don’t have to clean it at all. I am wondering if the Speedcoat-49 coating would extend the time before I start to get the build up of moss/algae and barnacles.

In salt water specifically, I don’t think the Speedcoat-49 would extend the amount of time before the fouling begins to build up, but it would make cleaning it up much easier. However, I do not like Speedcoat-49 in barnacle infested water. It is not better than a standard anti-fouling, and I do not want disappointed customers.

Where can I pick up some

Scott, I purchased Speedcoat-49 for a racing sailboat. Unlike a motorboat that benefits from dimples, racing sailboats benefit from a fair, smooth, burnished finish. I read your application notes, and it states to avoid sanding. Why? Because, I plan on burnishing the finish to 1500 grit.

Because the Speedcoat-49 gets it’s beneficial attributes from the chemistry and the non-stick nature of the coating… by smooth sanding or burnishing, you are simply removing an amount of the coating. Sand if you must, but I’d rather see you leave the surface as it is. If you want the smoothest surface possible, spray it on an there will be no need to remove any dimples.

Good news for Wetlander, I will be buying more gallon kits. I will be burnishing to 1500 grit. Sailboats need at least a bottom wetsanded to 400 grit at a minimum for speed regardless of coating type. I will need to compensate for at least two coats loss for leveling and burnishing. So, probably 5 coats will be applied by flock foam roller. The boat is on Lake Ontario in NY, so we will see how well it works next season in Sodus. Thanks!

Hi Scott, I have a 2013 62 Princess and the bottom of the boat is being sand blasted completely. I am applying propspeed on all metals and was looking for something to cover the rest of the hull that would protect and improve overall performance. Will your product accomplish this?

Are you in salt water, or fresh? What do you use the boat for? What is/was on the bottom that you are now sandblasting off? What do you mean by overall performance? Feel free to call me at 518-469-3612 or email me at [email protected] if that is easier for you.

So I have your product on my boat. I have bumped and dinged it. Can I sand and apply to only the spots I need to. Basically like touch up.

hi… Im from India

can i apply speed coat on wooden boat…?

Yes, you can apply Speedcoat-49 to a wooden boat, but ONLY if it has a layer of fiberglass and epoxy on there already… I do not like Speedcoat-49 on BARE wood.

Can speedcoat 49 applied to outrigger canoes like these? https://www.kaiwaa.com/draco-oc1

Hi Jennifer,

As long as the final “water facing” layer on these canoes is either gelcoat, an epoxy resin, polyurethane or carbon fiber, then yes. Based on the shine in the pics, I am going to guess it is a clear coating that has been buffed, but that is a guess. I have sent in an email to the company to ask what the specific outermost coating is… I hope to hear back from them and I will come back here and follow up.

Thanks, Scott H.

Follow up: Alicia at the Kai Waa company responded with the following statement “The factory finish is a marine grade acrylic urethane clearcoat, over the basecoat on top of carbon fiber.” Therefore, my answer is a definitive Yes, you can apply Speedcoat-49 over the existing Kai Waa hulls.

Leave a comment Cancel reply

-mike jensen, tritoon with 250 hp.

“Major difference. Looks awesome. Completely changes the boat. It looks great, wears great, and makes loading and unloading super easy”.

-Dave Jensen, Tritoon with 250 HP

“It’s the best thing I ever did for my boat” “after 450 hours of boating and trailering it still looks brand new. It’s the best coating in the world”

G. Bachman, 12 ft. aluminum boat

“I put that other order on my 12 foot tinny and it worked great. I got 12 1/2 mph out of a 6 hp 4 stroke when the boat was fully loaded with about 450 lbs ( gear, trolling motor, battery and me), well up from the previous 9 mph! Doesn’t seem much but it makes a big difference on the water. And that stuff is pretty durable as well, even after driving the boat on the beach, banging it off a few rocks, barely a scratch! I had about 10% left over, even after putting on three thick coats!”

G. Chandler, boat racer

GRAY CHANDLER – PS. Just a little feed back on the Wearlon. We have been testing the Wearlon with other anti foul coatings in the Marina [ salt water ] . These have been in the water since last September. No effect at all on the Wearlon whilst the other coatings have snails, algae, etc all over them. Will give the test a full 12 months . At this rate the result for Wearlon is excellent. Cheers.

“I raced last weekend with both the hydro and runabout. (Both are coated with Wearlon). I won both the DASH FOR THE CASH (one of the hardest races in the country to win) and the North American Championship in CSR. So, the wins just keep on coming and Wearlon is a part of the success.

DuckManDan, Tritoon Pontoon

I put the Speedcoat 49 on my tri-toon and I love it, worked perfect, everybody now wants it at the marina, no poontoon cleaning yea! No grass build up nice.

Website Powered by WordPress.com .

- Copy shortlink

- Report this content

- Manage subscriptions

Boat Reviews

- Boats Specs

- Marine Pros

- Boat Insurance

- Boat Warranties

- Boat Transport

- Boat Towing

- Marine Forecasts

Your Ultimate Boating Resource

Sailing Smoothly: The Best Guide to Selecting the Perfect Bottom Paint for Your Boat

Maintaining your boat’s performance and longevity is deeply anchored in the choice of the right bottom paint. It’s not just about aesthetics; it’s about creating a shield against marine life that can slow you down.

Dive into this all-encompassing guide to discover how the right bottom paint, tailored to your boating lifestyle, can make a world of difference.

The Vital Role of Bottom Paint

Think of your boat’s hull as a warrior in constant battle against underwater foes. Without bottom paint, it’s vulnerable to fouling, which can lead to reduced speed and efficiency. The secret weapon? Bottom paint infused with biocides that repel these unwelcome guests, keeping your hull sleek and swift.

Exploring the Seas of Bottom Paint Choices

Navigating the world of bottom paints can be like sailing through uncharted waters. There’s hard paint for the long haul, ablative paint that gracefully wears away with use, and even eco-friendly options that embrace green sailing. Each type has its unique strengths, so your choice should reflect your nautical needs.

The Copper Conundrum

Copper-based paints have long been the go-to for their fouling-fighting prowess. But as we become more conscious of our environmental impact, it’s important to weigh the effectiveness against potential ecological concerns.

Tailoring Paint to Your Boating Style

Your boating habits are the compass that guides your choice of bottom paint. Whether you’re leisurely cruising or racing against the wind, there’s a paint that aligns perfectly with your aquatic adventures:

Cruising Boats

With sleek and sturdy boats, their hulls coated in durable paint, resist the corrosive forces of time and tide. These vessels offer unwavering protection, allowing you to sail confidently through any weather conditions.

Racing Boats

For those seeking speed, ablative paints provide a slick and clean surface that is crucial for cutting through the waves. Their sleek, streamlined bodies sliced through the water with precision and speed. Each boat was coated in a shimmering layer of ablative paint, creating a smooth and clean surface that was essential for achieving maximum velocity.

Factors to Navigate When Choosing Paint

The waters you sail, the material of your hull, and even local laws are crucial markers in your journey to the perfect paint:

As you glide through the vast expanse of ocean, the type of water beneath your boat plays a crucial role in determining the ideal paint for your vessel. The crystal clear waters of a freshwater lake call for a different coating than the salty waves of the open sea. And even the laws and regulations of the local area can impact your choice of paint.

Hull Material

Selecting the hull material for your boat is like choosing a vessel as a sailor. The material you choose will play a crucial role in determining which type of paint will adhere best and provide optimal protection for your boat. Think carefully about your options, for the material itself can greatly impact the performance and longevity of your watercraft on the open seas.

DIY or Professional

Taking on a DIY project can be both exciting and daunting. Are you confident in your skills to paint your own ship, or will you leave it to the professionals? Consider the type of paint you choose–some are more forgiving for those without professional experience. As you set out on this endeavor, envision yourself as a deckhand navigating rough seas, armed with your chosen brush and paint, ready to transform your ship into a masterpiece.

Local Rules of the Sea

As you sail the open sea, always keep a vigilant watch on the horizon for any local regulations that may dictate your voyage. Pay special attention to any restrictions regarding copper-based options, as they may affect your journey in unexpected ways. Stay informed and navigate confidently to ensure smooth sailing ahead.

Final Thoughts

Your boat is more than a vessel; it’s a testament to your passion for the sea. Choosing the right bottom paint is a crucial step in ensuring it remains your faithful companion on countless voyages. With a keen understanding of the types of bottom paint and a thoughtful consideration of your boating style and environment, you can set sail confidently, knowing your boat is as ready for adventure as you are. Keep your hull in prime condition, and the sea will always welcome you with open arms.

RELATED ARTICLES

Overview of the 2024 sea-doo rxp-x 325, overview of the 2024 parker offshore 2900 cc, what your boat’s beam is and why it matters, power cats of 2024: ultimate guide to the top power catamarans this year, navigating the heat: 10 safety tips for a safe boat ride in the summer heat, latest posts, don't miss, our newsletter.

Get the latest boating tips, fishing resources and featured products in your email from BoatingWorld.com!

What type of wood is used for pier pilings?

What is the difference between a dock and a floating pier, what is the proper technique for pulling a beginner wakeboarder, what does ‘no wake’ mean on a lake, what is the difference between wash and wake, highs, lows, and tidal know-how: a deep dive into ocean currents, 10 essential tips for fishing near private property, the benefits of using a drift sock: guidance for anglers, lure fishing: secrets for imitating live bait and attracting fish, explore the untapped depths of america’s best bass fishing spots, outboard motor maintenance: tips for keeping your engine in top shape, the essential boat tool kit: tools every boater needs, diy boat building: 8 tips and tricks for building your own vessel, the art of miniature maritime craftsmanship: ship in a bottle, antifouling paints: a guide to keeping your boat shipshape, beginner’s guide to standup paddle boarding: tips and techniques, boating for fitness: how to stay active on the water, kayak safety: how to stay safe on the water, anchoring in a kayak or canoe: how to secure your small boat, overview of the 2024 yamaha 252sd, overview of the 2024 tiara yachts 48 le, overview of the 2024 bass cat jaguar sts, 2024 pursuit os 445: an overview, 2024 aquila 47 molokai review, 2024 sea-doo switch 13 sport review, gear reviews, megabass oneten max lbo jerkbait review, fortress anchors fx-7 anchoring system review, fortress anchors fx-11 anchoring system review, fortress anchors commando anchor kit review, fortress anchors aluminum anchors review, stay in touch.

To be updated with all the latest news, offers and special announcements.

- Privacy Policy

- AROUND THE SAILING WORLD

- BOAT OF THE YEAR

- Email Newsletters

- America’s Cup

- St. Petersburg

- Caribbean Championship

- Boating Safety

- Ultimate Boating Giveaway

Best Bottom Paint for Racing Boats

- By Ralph Naranjo

- Updated: August 1, 2007

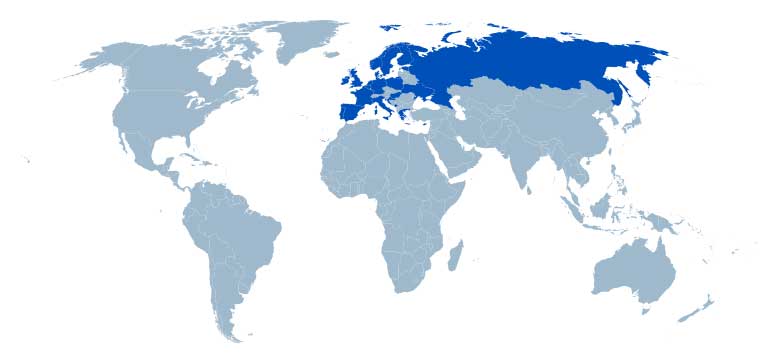

Research and real world feedback from competitive sailors confirms that the best bottom paint systems largely depend on geographic location. Differences in temperature, salinity, dissolved oxygen, and sunlight, as well as the length of the in-water season all impact bottom paint performance.

To better understand what worked best and where, we caucused speed shops and raceboat-favored boatyards around the country. Opinions varied, but a few points of consensus carried from one location to the next. One given was that a carefully faired keel and an epoxy primed and smoothly sanded bottom was the required starting point for all products. Another was that the higher the level of competition, the more often the bottom would be cleaned during the season.

From there, recommendations about the best bottom paint seemed to split down the middle with half favoring soft ablative coatings that hydrolyze, or slowly wear away to expose a fresh layer of slime-fighting chemicals. The other half favored hard, modified epoxy paint that can be scrubbed, wet sanded, and burnished to the point where the bottom looks like a polished beryllium sphere.

Shops servicing the needs of top-tier racers tended to favor the latter while those with predominantly club racer clientele felt the best bang for the buck came from high-biocide ablative coatings sprayed by a competent applicator.Paul Miller, a Naval Architecture Professor at the U.S. Naval Academy, who regularly tank tests slippery surfaces, recently reiterated that biological fouling starts within a couple of days of immersion, and even the first layer of bacteria can increase skin drag. He also pointed out that research has shown that a slippery coating does not in itself create less skin drag, but it does create a surface that marine plants and animals are less able to adhere to.

Developing a faster surface is about retaining laminar flow over more of the submerged hull skin, and shy of illegal practices, such as injecting polymers, detergents, and other chemicals into the water flow adjacent to the hull skin, smoothness and hull fairness are the variables worth improving. Paints, patents, and promisesBottom paints with chemicals defined as toxic to a wide range of marine organisms have been progressively removed from the market, and manufactures are developing effective ways to minimize biological growth.

In recent years, the definition of hazardous material has expanded to include Tributyltin (TBT)-a tin-based compound that is effective in bottom coatings. It remains legal for vessels longer than 82 feet, but its days are numbered. Soon it will join arsenic, mercury, and lead on the list of materials to be kept out of the water column. The importance of this development is crucial to competitors sailing to or shipping boats to Europe where tin has long been completely outlawed. Boats entering European waters must have a document detailing the coatings applied to their underbody-each layer, not just the last coat.Copper is now in the sights of regulatory researchers, and is already outlawed in some parts of Europe.

The result is new renditions of antifouling coatings must be made with less toxic or even non-toxic material. Making biocides that don’t end up in the environment is a priority as is further development of coatings that are too slick for organisms to attach to. Progress has been made, we have yet to surpass the performance of conventional top-of-the-line biocide-loaded paints, which are not as effective as tin-laced paints, and which have disappeared from U.S. and European chandlery shelves. Sailors are good stewards of the environment, but when it comes to bottom paint we’re still waiting for a “green” solution that can live up to the performance sailor’s needs.

The status quo is a multi-track approach-products with higher copper content still hold the antifouling edge. But, to racers there’s a second, highly valued characteristic of bottom paint-the ability to polish it to a smooth, slick surface. This is why ablative coatings that hydrolyze gained so much initial appeal. Their self-polishing chemistry releases biocide throughout the season, creating a near steady state antifouling quality. There’s also the upside of a smooth surface and an ability to haul and re-launch without destroying the antifouling quality of the paint. This triple set of advantages is further bolstered by zero paint buildup, as well as a surface that actually grows smoother with time. The problem was these claims were overly enthusiastic, and to really be ready for an important regatta, the bottom still needed to be wiped or scrubbed, a process that removed a significant amount of material, especially if done every couple of weeks.

Traditional hard, high-copper non-ablative bottom paints continue to have a strong following. They provide high initial antifouling quality and can be wet sanded to a smooth surface. In regions where the sailing season amounts to less than half of the year, and the normal routine includes regular bottom scrubs, these hard durable surfaces still make sense especially when the bottom is painstakingly wet sanded and burnished. Seasonal paint buildup is an inherent problem with hard coatings, and over a few years the skin can become cracked, chipped, or flaked.

Once this happens, it’s time for a labor-intensive bottom strip and paint makeover. Care must be taken during this process not to damage the fairness of the underlying surface.Slick, low-drag coatings are also on the market, and they deter fouling through the physical nature or lubricity of their skin rather than through copper content or other toxins. They’re effective in regions where fouling is less active, but they need to be carefully applied in order to develop as flawless a surface as possible. Some are soft and the surface may be wiped with a sponge but not scrubbed with an abrasive pad. A weekly wipe down by a swimmer with a sponge keeps the surface functional for the season, but if a month of inactivity slips by, barnacles may adhere to the surface and the show is over.

While regulations steadily eliminate biocides from antifouling coatings, other factors are conspiring to increase fouling rates. In some harbors it’s increased nutrients from farm run off or sewage treatment plants that boosts growth. Warmer water associated with global warming, and in some cases, better water quality are associated with the higher growth rates of organisms clinging to boat bottoms. The Mid-Atlantic has been plagued by an upturn in Bryazoan growth, a tenacious black mat-like coating that thrives in low-salinity conditions.

Barnacle growth in southern waters is booming. Ballast water dumped by globe-girdling freighters bring new organisms to local estuaries, and where conditions are right, they, too, find a new home on your boat’s keel, rudder, or hull skin. New products from companies such as E-Paint, which use zinc rather than tin or copper looking promising, but the best way to pick the right paint product for your racing commitment and local waters is to see what the industry experts use, check with others in your marina, and see for yourself which products are doing the best job.The CostPaint is the last thing to skimp on, and even budget-bound racers should invest in the best performing material for their part of the country.

The cost of a haul out, prep work, spray application, and diver service significantly exceeds the material cost of what’s in the can. Skimping on the quality or quantity of paint just doesn’t make sense. The big question is the level of finish desired, the cost of the management routine associated with bottom maintenance, and whether or not you bite the bullet and pay for the spray application of a hard finish product, the associated wet sanding, and also shoulder the cost of regular dive service that goes hand-in-hand with the top-tier competitor approach to bottom finish. Or, you opt for an ablative, self-polishing paint that requires no wet sanding, fewer bouts of bottom cleaning, and is perhaps less effective as a low-drag surface. Do-it-yourself prep work can help lower the application cost, but many yards mandate that they do all of the bottom work.Bottom Paint ResourcesAwlgrip: www.awlgrip.com E-Paint: www.epaint.net Interlux: www.interlux.com Pettit: www.pettitpaint.com Sea Hawk: www.seahawkpaints.com

- More: Sailing Gear

Comfort Rules with Mustang’s Minimalist Buoyancy Aid

Smart Polars Are Here

Reproofing May Be Required

Wingfoiling Gear: A Beginner’s Guide

Mistakes And Misfires On the Final Day of Cup’s Preliminary Regatta

Emirates Team New Zealand Remain the Bullies of Barcelona

Start-Box Sparring in Barcelona on Day 2 of Preliminary Regatta

- Digital Edition

- Customer Service

- Privacy Policy

- Terms of Use

- Cruising World

- Sailing World

- Salt Water Sportsman

- Sport Fishing

- Wakeboarding

- International Marine Coatings

- International Protective Coatings

VC Offshore Regatta Baltoplate

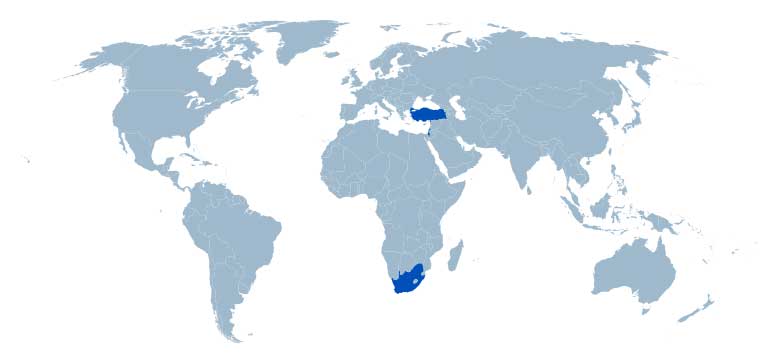

VC Offshore Baltoplate is a specialized hard antifouling for the dedicated racing or high performance boat, combining antifouling protection with the smoothness and low friction of a racing finish. For use on fiberglass, wood and primed metals (except aluminum), with proven performance on winning boats.

Not for use in California

Find a retailer

There are many stores that sell Interlux products throughout the United States. Find a retailer that's near you.

Find a distributor

There are many distributors of Interlux products throughout the United States. Find a distributor that's near you.

Good to know

- Low-friction antifouling for powerboats and sailboats

- Sand and polish for a gleaming metallic finish

- Suitable for use in all waters

Available colors

Download technical datasheet.

Contains detailed information on everything from the substances used to the application method.

- Technical datasheet - EN (PDF 149KB)

Technical data excerpt

* Method for professional use only

Safety information

The safety datasheet contains detailed information for the current formulation of this product such as hazardous ingredients, first-aid measures, fire-fighting measures, handling and storage. To make sure you have the right datasheet, please find the corresponding color and formula on your can. The formula is usually on the bottom. We provide safety datasheets for each latest formula. For missing safety datasheets, please visit our MSDS search site

Metallic Gray

- Sales code R3950

- Revision Date 20190721

Other information

- Is my new antifouling compatible?

Application guide

- English – Antifoulings and the environment including tear-out maintenance Guide

- English – Lakeland boating brochure

Suggested protective equipment

- Protective equipment overview

Advice on how to avoid problems

- Solve common problems

Check if this product is compatible with your current antifouling product

Simply use this tool to check compatibility with the antifouling product you already have on your hull. If you need any assistance, feel free to contact us for support.

Related products

Fiberglass Surface Prep

Removes contamination to the fiberglass bottom of new boats or unpainted hulls to aid adhesion.

InterProtect 2000E

Specially formulated with Microplates®, it protects fiberglass hulls from water absorption, which can lead to osmotic blistering.

Special Thinner 216

A fast evaporating solvent which improves paint drying in cold climates and makes spray application easier.

Although every effort has been made to ensure the colors on screen are as close as possible to actual paint colors, we cannot guarantee an exact color match. Paint swatch colors will vary depending on your screen settings and resolution. The manufacturer cannot be responsible for slight variations.

- Metallic Gray R3950

Paint needs

Calculate how much paint you need

For professional use only

Because of the application method required for this product, it is labeled for professional use only. This product is only for use by specialists with a license to use professional boat paint products.

How much paint do I need?

We'll help you calculate how much paint is needed.

What product do you want to paint

What type of boat.

Full bodied craft

Fin keeled racing craft

Medium draft racing craft

What is the underwater area?

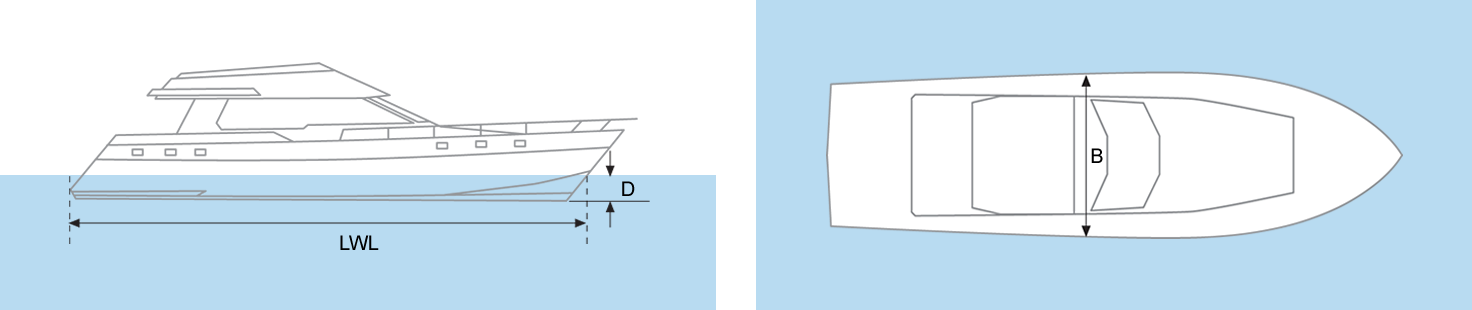

1 x LWL x (B+D) = Underwater Area (m 2 )

0.5 x LWL x (B+D) = Underwater Area (m 2 )

0.75 x LWL x (B+D) = Underwater Area (m 2 )

Abbreviations LOA = Length Overall LWL = Length Waterline B = Beam D = Draft F = Freeboard

Length waterline (Meters) (Feet)

Draft (Meters) (Feet)

Beam (Meters) (Feet)

Total boat area (Meters) (Feet)

What application method?

* For professional use only

Recommended no. of coats: ?

How many coats do you want to apply?

If you put less than the minimum recommended numbers of coats, it may affect the performance of the coating.

To paint a ? x ? x ? ?? , with ? coats

You'll need ? litres of

Warning that this tool is an estimator only

Paint your boat like a pro

Find the best products to keep your boat in great condition

Get all the support you need to paint with confidence

Benefit from our continuous innovation and scientific expertise

Select your country

Our products and guidelines are customised for each country. Please select yours below.

- Canada Canada

- United States United States

Asia Pacific

- Australia Australia

- New Zealand New Zealand

- Singapore Singapore

- België Belgium

- Hrvatska Croatia

- Danmark Denmark

- Suomi Finland

- France France

- Deutschland Germany

- Ελλάδα Greece

- Ireland Ireland

- Italia Italy

- Nederland Netherlands

- Norge Norway

- Portugal Portugal

- España Spain

- Sverige Sweden

- United Kingdom United Kingdom

Middle East & Africa

- South Africa South Africa

- Türkiye Turkey

Who's painting?

Choose one of the following to tailor the site to your needs.

- About the SA Forum

- Join the Forum

- Terms of Use

- Privacy Policy

- View All Listings

- Submit a Photo

- Submit an Article

- Contact the Site Administrator

- Contact the editor

bottoms, foils and finishes

One of our newest advertisers, Waterline Systems , shares some pretty good bottom and foil info right here.

When resins cure, they shrink. This is an inescapable fact of composite boatbuilding. Of the preva lent resin systems, epoxy shrinks the least, polyester the most and vinylester is somewhere in the middle.

The mold can be perfectly fair, but as the resin shrinks within the matrix, some areas end up low and others slightly high. This is not a manufacturing defect, but an unavoidable property of the materials used.

Fair vs. smooth

Many sailors mistake smoothness for fairness. We see people at regattas compounding, buffing and waxing their bottoms. They may be pretty proud of their obviously un-fair bottom. Fairness and smoothness are different things, with fairness being by far the more important in terms of speed.

Water flowing around a hull does not like to change direction. Highs and lows in your hull surface force the water to make a rapid direction change. This leads to a dramatic increase in drag. We aren’t making this up! Julian Bethwaite, the designer of the 49er ran full-size in the water tests between a faired 49er and a 49er fresh from the mold. Incredible as it seems, he found a 14% differ ence between the faired and un-faired hulls. He published his findings in Seahorse Magazine.

Smoothness

Sailors grossly over-estimate the value of smoothness. At the speeds we deal with on keelboats a 400 – 600 grit finish is all you need. It is not until speeds roll into the 30 and 40-knot range that smoother finishes add any benefit. Even at high speeds it’s good to note that the BMW Oracle AC Cat actually spent vast sums to carefully introduce roughness to the hulls via the 3M Riblet film.

Keel and Rudder fairing. Science and art

Keel and rudder fairing is substantially more complicated than bottom fairing. With the bottom we are only concerned with drag reduction. Keels and rudders both need to generate lift as well. Highs and lows are still vitally important, but now we add the need for a very precise shape.

Choosing the proper foils shape is the science part of the equation. Waterline Systems works closely with some of the world’s foremost hydrodynamic engineers and Naval Architects to help us determine the correct shape. We need to balance lift/drag, pressure distribution and the limitations imposed by class rules.

With the science in hand, art takes over. Actually getting the foil to the designed shape is pure art. Our team will fair more keels in a year than most yards do in a lifetime. Even with that level of experience, Company founder/President Randy Borges is still hands-on with each keel fairing pro ject.

‘ Club Racer’ / “Grand Prix’ – What’s the difference

Waterline Systems offers 2 basic levels of fairing service. Time is the difference. Block sanding is the time consuming part of the job. With every block-sanding pass, the surface gets a bit fairer. In a Grand Prix job, we do an additional few steps; filling with epoxies, and spend additional time block sanding.

The Club Racer bottom is really, really good. The Grand Prix bottom is better!

What is the ‘maintenance/ scuff and shoot’ bottom?

Over time, bottom paint loses its potency and epoxy primer gets a bit tired. Boats with our bottoms tend to get wet sanded a lot and eventually the paint just gets thin. The scuff and shoot is a re fresher. Since we know what is on the bottom, we can block sand the existing paint, re-shoot and then wet sand. The scuff and shoot gives you an extra fairing pass, and your bottom comes out bet ter than ever!

What is the ‘Cruising / Daysailor’ Bottom?

We’ve heard from plenty of customers who don’t race but still want a higher quality bottom paint job than they can typically get at their local boat yard. We sand, apply Interprotect 2000, sand and prep that then spray your choice of anti-fouling. The bottom will get a bit fairer, but we aren’t spending our time or your money aiming for fairness. A sprayed application of bottom paint is a whole lot smoother than a roller job!

What’s up with the hard line at the waterline?

There is a definite line, almost a ridge where the bottom job ends. We position this several inches above the static waterline. This really bugs some people but it shouldn’t. Even immersed, this line is in the very top layer of the water. This area is really turbulent and actually mostly bubbles. The smart guys tell us that it makes zero difference to boat speed and may actually create lift going up wind like a chine. Hum? Maybe that makes sense? Anyway live with it.

Materials

The materials we use are expensive. We occasionally hear from clients inquiring if we can use less expensive stuff. There are a few good reasons that we don’t: First, in the overall project, materials are a small percentage. Labor makes up the vast majority of the total. Second, we know they work. We stand behind our work and our suppliers stand behind their products and in the end, you win.

What products do you use?

Below the waterline, we exclusively stick with the AkzoNobel line of Interlux products. This in cludes solvents, epoxy fillers, barrier coat, primer and anti fouling coatings. Our manufacturing reps all shy away from the word paint these days. Modern coating systems (that’s what they call ‘em) are all designed to work together on a chemistry level. While most of us muddled through re medial chemistry classes. They have PhDs. It’s smarter for us to do what they say works! And they stand behind our applications.

Above the waterline we use Awlgrip, which is also from the AkzoNobel product line. After about 25 years, Awlgrip has really earned our trust. It can be difficult to work with, but we have the experi ence needed and it simply gives our customers the best finish and is the most durable product on the market.

Bottom Paints

What are our options on bottom paints?

Dry sailed Boats