Fuel Polishing - A Complete DIY Guide

Last Updated by

Daniel Wade

June 15, 2022

Fuel polishing is especially important for boats, as dirty diesel fuel can be a nightmare for boat owners and cause damage to engines.

Fuel polishing systems remove water, bacteria, fungi, dirt, and sludge from marine diesel and boat fuel tanks. Unlike standard filters and water separators, fuel polishing can remove microscopic contaminants and invisible emulsified water from diesel fuel.

In this article, we'll go over the benefits of fuel polishing systems, how they work, and whether or not you need one on your boat. We'll compare them to standard fuel filters and help you choose between these two common options. We'll also list and explain the parts you need to build your own DIY fuel polishing system.

We compiled information for this article from numerous sources on fuel polishing, diesel quality, and manufacturers of filtration systems for marine and land-based use. We also studied the market to find the latest fuel polishing system prices, technology, and quality.

Table of contents

What is Fuel Polishing?

Fuel polishing is a technical term for a complicated fuel decontamination process. Fuel polishing removes numerous contaminants from fuel that standard automotive-type fuel filters don't. Fuel polishing is especially important for marine applications, as fuel stored above ground is prone to contamination.

Standard fuel filters remove large particles and sediment (I.E., dirt) from gasoline or diesel using a membrane, such as paper or mesh. This works well for underground fuel storage, as fuel at gas stations is drained and replenished frequently. For marine applications, particularly diesel, additional steps must be taken to cleanse fuel of impurities.

What Does Fuel Polishing Do?

Fuel polishing removes large particulates (such as dirt) along with water, bacteria, fine particles, and other organic compounds. Here are the primary contaminants that are removed using fuel polishing.

- Emulsified Water

- Dissolved Water

- Organic films

Fuel polishing is used primarily for diesel fuel, as diesel engines are more sensitive to fuel quality than gasoline engines. This is because diesel engines use compression to ignite fuel (as opposed to a spark plug), so any water or other contaminants can severely damage the high-pressure systems.

A small amount of dirt can clog injectors, and water can cause the engine to self-destruct because it doesn't burn away and can't be compressed. Water is the biggest danger to diesel engines, and it's a common contaminant in marine diesel fuel.

How Fuel Polishing Works

A fuel polishing system is usually connected directly to a diesel tank with two separate lines. The intake line, diesel is drawn into the polisher with a pump, is situated with its opening at the lowest possible point in the tank. This is because scum and contaminants tend to settle at the bottom, where the hose can easily pick them up.

Fuel is pumped into the polisher and then back into the tank from the very opposite top relative to the intake. This prevents polished fuel from being drawn back into the polisher.

Stages of Fuel Polishing

The most basic fuel polishing systems contain a minimum of two cleaning apparatuses, known as 'stages.' The first stage of fuel polishing is usually filtration and free water separation. The second stage utilizes a coalescer, which removes emulsified water, which is essentially dissolved moisture.

Free Water Separation

Free water is liquid water that settles inside a fuel tank. It isn't dissolved into the diesel, and it's easy to remove using a centrifugal water separator. Many boats already have a water separator installed, so this process will be familiar to some. The centrifuge works by spinning the solution and separating fuel and water based on their densities.

Centrifugal separators are also useful for filtering out large particles and sludge, such as some of the build-up caused by diesel bug. However, a centrifugal separator cannot remove all contaminants.

Fuel polishing systems filter fuel at least once, usually before entering the coalescer. These fuel filters use a very fine membrane to separate out all particles of dirt, grime, and other gunk to about 25 microns in size. However, filters and centrifugal water separators can't remove emulsified water or some dissolved contaminants from diesel fuel, which is why a coalescer is necessary after filtration.

A fuel polishing coalescer is essentially an advanced filter. It is capable of separating different chemicals based on molecular weight, and it can remove dissolved and emulsified water and other contaminants from diesel fuel.

Some coalescers utilize electrically charged plates, while others rely on purely mechanical processes. Many fuel polishing coalescers also contain a fine filter to remove any remaining particles that escape the first two stages.

Why is Fuel Polishing Necessary for Boats?

Diesel-powered marine engines are robust and reliable. That said, they're still sensitive to fuel contamination, as bad fuel is one of the most common causes of engine failure at sea. Marine diesel engines are victims of a kind of catch-22, as they require more careful attention to fuel, but their fuel is more likely to be contaminated.

Marine diesel tanks get dirty. Shore-based storage tanks, especially at marinas, are often contaminated due to infrequent use or lack of cleaning. Particulates such as bird droppings and rust are particularly common. A quick fuel sample from a local marina revealed that there was a visible amount of dirt in the fuel, and the presence of dissolved water couldn't be ruled out.

A marine fuel-polishing system removes water and other contaminants from fuel. These systems are compact and reliable and an absolute necessity on marine diesel power plants.

Is a Standard Fuel Filter Enough?

Some factors to consider when choosing between a standard filter and a fuel polishing system are the size of your boat, how far you intend to sail, and the size of your fuel tank.

Generally speaking, a standard fuel filter is not enough for a large diesel-powered boat to operate safely. This is due to the high amount of contaminants found in marine diesel fuel. Having a basic fuel filter is still better than having nothing at all, though a robust fuel polishing setup is always the best bet.

If you don't have room on your boat for a complete fuel polishing setup, make sure to install a fuel and water separator. This will ensure that you won't experience hydro-locking, which is a condition where water prevents a cylinder from compressing, and damage occurs. An in-line fuel and water separator is much cheaper than replacing a bent connecting rod.

What is Diesel Bug?

Diesel bug is a rather horrific-looking bacterial or microbial infection that affects diesel and fuel-containing parts. The condition occurs when water permeates the fuel and allows bacteria or fungus to enter and thrive within it. Diesel bug is especially common in biodiesel and in marine diesel tanks.

Diesel bug causes an enormous amount of sludge to build up in hoses, on engine parts, in and around the fuel tank, and even inside of your injection pump.

Does Fuel Polishing Remove Diesel Bug?

Fuel polishing is the best way to prevent diesel bug from migrating to more sensitive parts of your engine from your fuel tank. If you have the option, it's also best to fill your tanks with polished fuel to prevent diesel bug from infecting your tank and clogging filters.

How Much Does a Fuel Polishing System Cost?

Fuel polishing systems are relatively expensive, and the cost isn't justified on all vessels. The most affordable fuel polishing systems cost anywhere between $1,500 and $3,500. Price usually increases as polishing capacity expands.

The most basic fuel polishing systems at entry-level prices use very basic control systems and may require manual input to start and stop. More expensive fuel polishing systems, which typically cost more than $3,000, come with very advanced and reliable automated controls.

High-end fuel polishers are self-regulating and can keep your fuel tank clean for a long time. High-tech sensors monitor the life of filters, the quality of the fuel in your tank, and how long it'll take to polish the remaining fuel.

Do I Need a Fuel Polishing System?

Do all diesel-powered boats need a fuel polishing system, and are fuel polishing systems available for boats of all sizes? The short answer is no. So how do you know if you need a fuel polishing system?

Generally speaking, fuel polishing systems are most effective for vessels with a large fuel capacity. A 200-gallon tank can be scrubbed using an inexpensive fuel tank cleaning machine, whereas a 2000 gallon tank could benefit from a small fuel polisher.

In most cases, diesel-powered boats less than 40 or 50 feet in length probably don't need a fuel system, though small fuel polishers are available for medium-sized boats. In all other cases, a high-quality fuel filter and a centrifugal water separator are good enough to get the job done, and you'll likely be able to solve any contamination issues some other way.

The one notable exception is with ocean-going vessels, even smaller boats less than fifty feet in length. Boats that travel long distances over the open ocean cannot afford to risk a catastrophic failure due to diesel contamination. A fuel polishing system is a mechanical insurance policy against preventable breakdowns at sea.

Can You Build a Fuel Polishing System?

Yes, it's relatively easy to build your own fuel polishing system if you understand the operational principles and acquire all the right parts. The most important things to consider when building your own fuel polisher are proportioning and safety.

The majority of fuel polisher parts are available stand-alone fuel system add-ons. These include centrifugal separators, filters, electric fuel pumps, and coalescers. When acquired separately, these parts cost significantly less than many complete systems.

You can add your homemade fuel polisher to your existing fuel system as well and keep your fuel water separator and original fuel filter. So if you're going to build your own fuel polisher, it may be a good idea to upgrade the entire filtration system.

Can You Rent a Fuel Polisher?

In most cases, you can't just 'rent' a fuel polisher, though you can utilize the services of a fuel cleaning company. There are dozens of fuel cleaning companies located along the coastal United States that specialize in cleaning marine fuel tanks and purifying diesel fuel.

The length of the process and the cost depends on the amount of fuel you need polished and your location. Hiring a fuel polishing company to purify your fuel is an economical way to rid your tank of sludge, diesel bug, and other undesirable and potentially harmful chemicals.

Related Articles

I've personally had thousands of questions about sailing and sailboats over the years. As I learn and experience sailing, and the community, I share the answers that work and make sense to me, here on Life of Sailing.

by this author

Most Recent

What Does "Sailing By The Lee" Mean?

October 3, 2023

The Best Sailing Schools And Programs: Reviews & Ratings

September 26, 2023

Important Legal Info

Lifeofsailing.com is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to Amazon. This site also participates in other affiliate programs and is compensated for referring traffic and business to these companies.

Similar Posts

How To Choose The Right Sailing Instructor

August 16, 2023

Cost To Sail Around The World

May 16, 2023

Small Sailboat Sizes: A Complete Guide

October 30, 2022

Popular Posts

Best Liveaboard Catamaran Sailboats

December 28, 2023

Can a Novice Sail Around the World?

Elizabeth O'Malley

4 Best Electric Outboard Motors

How Long Did It Take The Vikings To Sail To England?

10 Best Sailboat Brands (And Why)

December 20, 2023

7 Best Places To Liveaboard A Sailboat

Get the best sailing content.

Top Rated Posts

Lifeofsailing.com is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to Amazon. This site also participates in other affiliate programs and is compensated for referring traffic and business to these companies. (866) 342-SAIL

© 2024 Life of Sailing Email: [email protected] Address: 11816 Inwood Rd #3024 Dallas, TX 75244 Disclaimer Privacy Policy

- New Sailboats

- Sailboats 21-30ft

- Sailboats 31-35ft

- Sailboats 36-40ft

- Sailboats Over 40ft

- Sailboats Under 21feet

- used_sailboats

- Apps and Computer Programs

- Communications

- Fishfinders

- Handheld Electronics

- Plotters MFDS Rradar

- Wind, Speed & Depth Instruments

- Anchoring Mooring

- Running Rigging

- Sails Canvas

- Standing Rigging

- Diesel Engines

- Off Grid Energy

- Cleaning Waxing

- DIY Projects

- Repair, Tools & Materials

- Spare Parts

- Tools & Gadgets

- Cabin Comfort

- Ventilation

- Footwear Apparel

- Foul Weather Gear

- Mailport & PS Advisor

- Inside Practical Sailor Blog

- Activate My Web Access

- Reset Password

- Customer Service

- Free Newsletter

Whats the Best Way to Restore Clear Plastic Windows?

Beneteau 311, Catalina 310 and Hunter 326 Used Boat Comparison

Maine Cat 41 Used Boat Review

Cheoy Lee Clipper 36 & 42 Used Boat Review

Tips From A First “Sail” on the ICW

Tillerpilot Tips and Safety Cautions

Best Crimpers and Strippers for Fixing Marine Electrical Connectors

Thinking Through a Solar Power Installation

Stopping Mainsheet Twist

Working with High-Tech Ropes

Getting a Clue for the Blown-Out Clew

Monel Seizing Wire is Worth the Extra Cost

Fuel Lift Pump: Easy DIY Diesel Fuel System Diagnostic and Repair

Ensuring Safe Shorepower

Sinking? Check Your Stuffing Box

The Rain Catcher’s Guide

Boat Maintenance for the Technically Illiterate: Part 1

Mastering Precision Drilling: How to Use Drill Guides

Giving Bugs the Big Goodbye

Galley Gadgets for the Cruising Sailor

Those Extras you Don’t Need But Love to Have

UV Clothing: Is It Worth the Hype?

Preparing Yourself for Solo Sailing

How to Select Crew for a Passage or Delivery

Preparing A Boat to Sail Solo

On Watch: This 60-Year-Old Hinckley Pilot 35 is Also a Working…

On Watch: America’s Cup

On Watch: All Eyes on Europe Sail Racing

Dear Readers

Chafe Protection for Dock Lines

- Inside Practical Sailor

Diesel Fuel Polishing Systems

If you plan on doing some long-term cruising with an auxiliary diesel, and expect to be picking up fuel in out of the way places, or you find you find yourself changing dirty fuel filters frequently, then it might worth the time and expense to install a fuel polishing system. First, of course, you want to diagnose the source of the problem.

A fuel polishing system is essentially a recirculating fuel line, a pump and a pre-filter. It won’t fix whatever is causing your clogged filters—likely algae (growing in untreated fuel) or asphaltenes (microscopic tar particles in the fuel) are common. However, it will set you on your way again, and delay or, with routine use, avoid the next clogged filter.

As the fuel is polished it is circulated through coarse fuel filters with a water separator until the fuel runs clean and dry, with all the water stripped away. The severity of the contamination will determine how coarse a filter to use, but many polishing systems advise starting with 30 microns and working down to 10 micron. Ten microns is the common coarseness for a pre-filter; the final spin-on engine-mounted filter is usually between 2 and 7 microns. If your fuel is severely contaminated, these filter expenses can add up.

You could plumb some fuel-rated valves and hoses and use the ship’s own fuel lift pump and pre-filter to create a polishing system system. However, the OEM pre-filter cartridges are usually expensive, and each time you polish the tank, you are putting an extra burden on your lift pump.

One of the first skills the new owner of an old auxiliary-powered sailboat masters is changing the diesel fuel filters and bleeding the fuel lines. The next step is to address the source of the gunk that clogged the filter, but even meticulous fueling practices and a well designed fuel tank won’t guarantee that dirty diesel fuel will never haunt you again.

Our former boat, a 60-year-old ketch, had black iron tanks that proved to be one of the worlds most efficient microbe farms. Rather than replace the diesel fuel tanks (which was beyond our budget), we had the tanks professionally cleaned, changed the fuel-feed setup, and installed a 7-gallon day tank with a home-made fuel polishing system (using a continuous duty oil-transfer pump and an old Dahl 101 filter housing, which used relatively cheap replacement filters). We never had fuel problems again, but I wouldn’t recommend this arrangement for a number of reasons, including the fact that the Dahl filters were a pain to change. Although more expensive, an integrated and purpose-designed pump module and filter like the Parker Fuel Polisher is much easier to install and maintain.

Practical Sailor has looked at diesel fuel topic from many different angles and anyone dealing with fuel issues on an old boat would benefit from three articles in our archives. The first is our in-depth look at fuel tanks , focusing primarily on installation and material selection. (Aluminum is a cost effective choice, but good installation is key.)

The second article is our recent look at diesel fuel additives . This controlled test examined what worked best against bacteria and fungus in a diesel fuel. As we found from that study, trying to cure a contaminated diesel fuel tank with additives alone is not nearly as effective as a regimen that includes polishing.

If you do decide to build your own polishing system, just be sure to follow ABYC guidelines for fuel systems, at the peril of nullifying your insurance coverage—or worse. If a DIY fuel system upgrade is too intimidating, then check out our short reviews of the fuel polishing system from Parker , parent company of the well-known Racor brand fuel filters, and a similar unit, the original Filter Boss . Although the original Filter Boss is no longer available, the Keenan Filter is closely based on that system.

And if you need your fuel filtered right away, most ports have one or more mobile services that can filter your fuel for for you. The service isn’t cheap, until you consider that it costs $300 to replace the filter on the high-volume fuel polishing carts that some of these small companies use.

If you are meticulous about fuel and curious about which “miracle-cure” additives on the market actually work, we’ve got a complete ebook “ Marine Fuel Additives ,” addressing the care and feeding of your fuel, whether it’s gasoline for the dinghy or diesel for the mothership.

RELATED ARTICLES MORE FROM AUTHOR

On watch: this 60-year-old hinckley pilot 35 is also a working girl.

Hi Darrell, good stuff but from personal experience of a circum nav, the Baja Fuel filter as well as a little additive is highly effective. Hugh

Fuel Rite additive has a very convincing webpage with video on how it’s product turns the bad stuff into burnable fuel. I first sourced it from home heating oil companies who used it to prevent their large storage tanks full of fuel from going bad. So if it is good enough for them …..? The supplier I get it from in Ontario Canada has a polishing business mostly based on back up generators for hospitals ect. Again if it’s good enough for him…? cheers RL.

We use the following system to good effect: First stage: 2 pass 30 micron/20 micron Second stage: 2 pass 10 micron/5 micron On engine: 10 micron Both the 1st and second stage filters have vacuum gages with telltales. I’ve got a squeeze bulb plumbed in to assist in priming All filters are Cummins spin on. Relatively inexpensive and easy to change.

Would love for you guys to do an article on the Diesel Dipper: https://www.marine16.co.uk/diesel-dipper-2/diesel-dipper

LEAVE A REPLY Cancel reply

Log in to leave a comment

Latest Videos

The Perfect Family Sailboat! Hunter 27-2 – Boat Review

Pettit EZ-Poxy – How to Paint a Boat

The Boat From True Spirit – Sparkman & Stephens

Top 5 Boat Hacks – Boat Maintenance Tips and Tricks

Latest sailboat review.

- Privacy Policy

- Do Not Sell My Personal Information

- Online Account Activation

- Privacy Manager

Practical Boat Owner

- Digital edition

How I built a £500 marine fuel polishing system to protect my boat from dirty diesel

- Graham Keating

- July 2, 2022

Diesel engines have simple tastes, says Graham Keating, but clean fuel is one that can’t be guaranteed in all corners of the world

Graham Keating testing his newly built, portable diesel polishing kit

Give our diesel engines clean fuel to drink, plenty of fresh air to breathe, plus a regular jump-start of amps, and they’ll happily run pretty well forever, given a little routine maintenance of course.

However, guaranteeing that crucial supply of clean fuel is becoming something of a headache for many sailors and it’s certainly challenged us aboard Maunie for the past few years. In 2012 my wife, Dianne, and I set off on a voyage that we’d long been dreaming of and was now, suddenly, a reality.

With our careers firmly paused, our house rented out, the car sold and our furniture in secure storage, we’d moved aboard our 1997 Vancouver 38 Pilot, Maunie of Ardwall , for an adventure that would take us from our home port of Dartmouth down to the Canaries, across the Atlantic to the Caribbean, through the Panama Canal and finally across the vast Pacific.

Our ‘we’ll only be away for about two or three years’ reassurance to our friends and family as we departed turned out to be very optimistic; five years later we finally fulfilled the fantasy of sailing our own boat under the iconic Sydney Harbour Bridge.

Dianne helms Maunie under the Sydney Harbour Bridge

Our unplanned tardiness was nearly all the fault of the Pacific Islands; having reached New Zealand in October 2013, we felt their magnetic pull, so we spent three winter seasons exploring the island nations of Tonga, Fiji and Vanuatu, returning to spend each summer cyclone season in New Zealand, before finally shaking ourselves free to return to ‘first world’ life after over 30,000 miles of sailing.

The remote islands of the Pacific suddenly focussed our attention on the issue of diesel quality in a way that we’d never previously considered. Through the daily cruisers’ SSB radio nets and conversations with other crews in idyllic anchorages, we heard of yachts being affected by contaminated diesel, some with serious consequences.

Even when fuel purchased in the islands appeared to be clean, it was widely rumoured that it was of distinctly inferior quality; certainly, Maunie ’s white transom would gain a sooty topcoat after any extended periods of motoring, a problem that magically disappeared after the first tank refill in Australia.

Fuel transport in Vanuatu

Marinas and alongside fuel-berths were a very rare luxury in the islands, of course, so we routinely bought fuel from often scruffy roadside garages, lugging heavy 25lt jerrycans to the dinghy dock and hoisting them aboard.

One example was in Vanuatu, where in 2016, at a ramshackle dinghy dock, we managed to borrow a rusty wheelbarrow from a hardware store to wheel our load of empty fuel cans across the wide and rather chaotic main road.

The proprietor of Luganville’s only fuel station was delighted to see us and our jerrycans, with their combined 150lt capacity. Almost all his other customers were local taxis – mostly tiny, Korean-built Daewoo Matiz cars that showed very few signs of maintenance – and we were amused to see that most of the drivers would put only one or two litres into their tanks.

Article continues below…

12 diesel bug treatments tested

Diesel bug can clog filters and starve your boat engine of fuel just when you need it most. Can diesel…

What’s the best boat fuel? Is it worth paying for premium? Ask the experts

PBO reader Roy Gwilliam asks: “I have a Yanmar 3YM20 engine in my Dehler 32, built in 2010. I generally…

It wasn’t uncommon to see the result of driver miscalculations with a taxi being pushed onto the forecourt, having run out of fuel a few metres short of the entrance.

The sight of a couple of British yachties, red-faced from both heat and exertion, filling and heaving jerrycans of diesel was clearly something of a novelty for the good humoured but slightly reserved locals. Financial transactions completed (and the diesel was, thankfully, very cheap there), we were ready to run the gauntlet of that busy road.

Refuelling routine

Having obtained our precious fuel and heaved it aboard the boat from the dinghy, our routine was always the same. Leaving the jerrycans to stand in the cockpit overnight to allow any impurities to settle to the bottom, we’d then peer in through the cap to get an idea of the quality we were dealing with.

We used a syphon, the end of its tube held at least an inch above the base of the can, to transfer the fuel into our main tank, with a Baja filter placed in the deck filler to strain out any remaining impurities or water.

Maunie ’s 53hp Yanmar 4JH2E is 25 years old and has 4,300 hours on the clock. Regular maintenance has kept it running smoothly

The last litre or so of fuel remaining in the can often had some ‘interesting’ debris in it, so we’d pour that through a fine gauze-lined funnel into a designated ‘dregs’ jerrycan that would be left to settle overnight again before its contents could be safely syphoned.

It was a very messy and unpleasant job that we didn’t relish but, with 100-hour precautionary changes of its primary fuel filter, our Yanmar engine thankfully never missed a beat.

Diesel bugged

In 2018, the demands of both time and work saw us take the decision to have Maunie shipped back to Southampton from Newcastle in New South Wales and, after that, undertake a major refit to replace her teak decks (a project covered in PBO June 2020 ).

Loading Maunie aboard a freighter in the east coast port of Newcastle, Australia, for the journey home

Our sailing had become constrained, at least temporarily, to the UK and Ireland. It was therefore ironic that it was here, in home waters, that we suffered our first ever fuel contamination problems as we motored down the Irish Sea last summer.

“What just happened?” Dianne and I looked at each other to confirm we’d both heard it, a momentary change in the engine note as we motored through a windless but rolling sea near the Isle of Man.

Seconds later, the Yanmar’s revs dropped away to a rough idle and, shortly after that, the engine died. This moment of surprised silence was to be our introduction to the dreaded diesel bug .

Maunie has slightly old-fashioned but effective water-separators and primary filters. We fitted the second one when we added an emergency fuel tank, to allow an easy change-over if the main filter became blocked

Since our return to UK waters, we’ve filled our tanks only at reputable marinas and fuel barges and have followed the advice to top-up fuel levels over winter to minimise the risk of condensation forming in the tank. The blockage of our primary filter, replaced only 80 hours previously, came as quite a shock.

Thankfully Maunie has a second emergency tank, complete with its own filter, so a simple switch-over of a couple of valves had the engine restarted and we were on our way again.

Fearing a potential repeat of the problem, though, we did stop the engine an hour later to carry out a slightly nausea-inducing swap of the engine’s primary filter element.

With Maunie ashore for the winter, we decided it was time to devise a way of keeping our diesel clean

Diesel bug has become an increasingly concerning issue, of course, and an excellent article in PBO’s sister-publication Yachting Monthly in February this year explored the issue in some detail .

The problem has been exacerbated by the introduction of FAME (Fatty Acid Methyl Esters), a bio-fuel element made from recycled cooking oil and vegetable oils, that is now being added to all road fuel (currently at an inclusion rate of 7%) and, unfortunately, to many marine fuels.

Adding a bio-fuel element to diesel of course makes complete sense to reduce the CO2 emissions of road transport and, according to the YM article, the addition level is set to rise to 12.4% by 2032.

We fitted this 60lt fuel tank before we sailed to Australia. It fits neatly under the floor of the pilothouse food locker

However, its introduction to marine fuels brings significant risks. The FAME is hygroscopic (clearly not great news in a damp marine environment), forming a viscous layer where it interfaces with any water in the fuel, and it also apparently reacts with minerals in the diesel to form carboxylic acid.

These thick, soapy contaminants can block the primary filter, as it did on Maunie , starving the engine of fuel at possibly a very inconvenient or even hazardous moment. Furthermore, the FAME element, being plant based, degrades over time, shortening the safe shelf-life of diesel to around six months.

The conclusion of the article was that boat owners need to take action to actively remove any water in their fuel, filter out any soapy contaminants before they can reach the engine’s in-line filters, and also to use an antioxidant additive to slow down fuel degradation.

The main 180lt stainless steel fuel tank sits under the cabin sole

The solution

Our own experience added an important job to our winter to-do list. We decided to install a fuel polishing system which would allow us to suck fuel from the bottom of our tanks, filter it to remove any water, debris and diesel bug and then return the clean fuel back to the top of the tank.

In common with many yachts, Maunie ’s 180lt main tank and her 60lt emergency tank both sit below the cabin sole in her deep bilges. They are accessible only via bolted-down top plates, each fitted with the various send and return pipes for the engine, generator and Eberspächer heater. Each plate has an additional, blanked-off screw cap.

Shopping list

Our original plan was to plumb in a permanent pump and filter system that we could run as and when required and we initially looked at a commercially available piece of kit called the Diesel Dipper.

Maunie on passage from Falmouth to the west coast of Scotland. Photo: Adam Kerner

However its price (around £900, plus the additional cost of valves and pipes), together with the slightly daunting complexity of plumbing it in, made us think again.

Besides, our experience of using jerrycans prompted us to design a solution that would allow us to simultaneously transfer and filter fuel from them, without the messy use of a syphon tube, as well as allowing us to access the bottom of the boat’s two tanks via their blanked-off caps.

A portable 12V system seemed like a practical solution and we turned to Beccles-based ASAP Supplies for advice on the necessary components.

In essence, the mechanical side of the system is a length of copper fuel pipe that can be bent gently to allow us to ‘hoover’ around the base of each tank, a Racor filter/water-separator, an electronic 12V fuel pump and some valves and flexible hoses.

An order to RS components completed the component shopping list, this time for cables, a switch and an electronic hour-meter, while an on-line search found CPC, a UK supplier of tough Chinese-made waterproof cases in which we would mount the whole thing.

Heading south past Ardnamurchan Point, near the Isle of Mull, July 2021, blissfully unaware of the diesel bug lurking in the tank

Assembly was pretty straightforward, though the addition of the hour-meter made the electrical connections slightly more complicated and required a junction box in which to mount it.

The 12V fuel pump only draws a couple of amps so a direct connection to a cigarette-lighter plug would have been an easy solution; however, the addition of the switch and timer seemed like a neater fix.

The pump delivers about 120 litres per hour, so the hour-meter allows us to work out how much fuel has been circulated each time we use the polisher, as well as logging the time between filter-element replacements.

The polisher’s feed and return copper tubes fit through a spare access port on the top of the fuel tank

I bolted the pump, filter and switch box onto a plywood board which was cut to fit into the plastic case. When not in use, the fuel hoses coil neatly into the case and there’s room for a spare filter as well.

The Racor filters, incidentally, have an additional water-blocking coating called Aquabloc and come in different gauges; we chose 10-micron as recommended but there is a 2-micron option.

With everything assembled, it was time to test it with a can of diesel and the car’s 12V supply. Once we were satisfied that all the fittings were free of leaks (I used Loctite 577 thread-locker on all the threaded connectors, just to be certain), we decided to conduct a properly challenging test and poured a third of a litre of water, coloured with black ink, into 15lt of clean fuel in the jerrycan.

The fuel polisher in action on board the boat

Pouring water into clean diesel felt very wrong, I can tell you, but we could clearly see it sink to the bottom of the can.

The roving copper pipe sucked it up with ease when we switched on the pump and we were delighted to see the Racor ‘turbine’ unit spin the water out into the bottom of its polycarbonate bowl.

Almost miraculously, after only about fifteen seconds, the jerrycan was completely clear of black water. Once the pump was switched off, the black water settled in the bottom of the bowl and it was then just a case of opening the Racor’s drain cock to remove it.

The finished system in its tough, waterproof case. There’s room for the coiled fuel hoses and a spare filter element. Valves are kept closed when not in use to prevent fuel leakage

For just over £450, plus our own time, we now have a hugely useful and reassuring piece of kit stowed in one of Maunie ’s deep bilge lockers.

We could have used a cheaper filter system – a CAV filter unit is less than a third of the price of the Racor, for example – but we had read nothing but excellent reviews, so the Racor it was.

We’ve now tried the system in Maunie ’s fuel tank and, after an hour, we were happy to find no water. However, there was some black debris that had dropped into the Racor bowl and the filter element, which is easily removed for inspection, was definitely slightly dirty, so it was a rewarding exercise.

The new fuel polisher allows us to start any major passage knowing that we’ve removed any water, debris or diesel bug from our tanks before it has the chance to block the engine filters.

Moreover, we now have a safe and easy way to transfer fuel from jerrycans to main tanks, we can also move fuel between our emergency and main tanks if required, and we have the ability to assist other boats experiencing fuel issues in remote anchorages. We’re hoping that we aren’t called upon to provide that service too often!

How to build a DIY fuel polisher

Summary of costs, including delivery

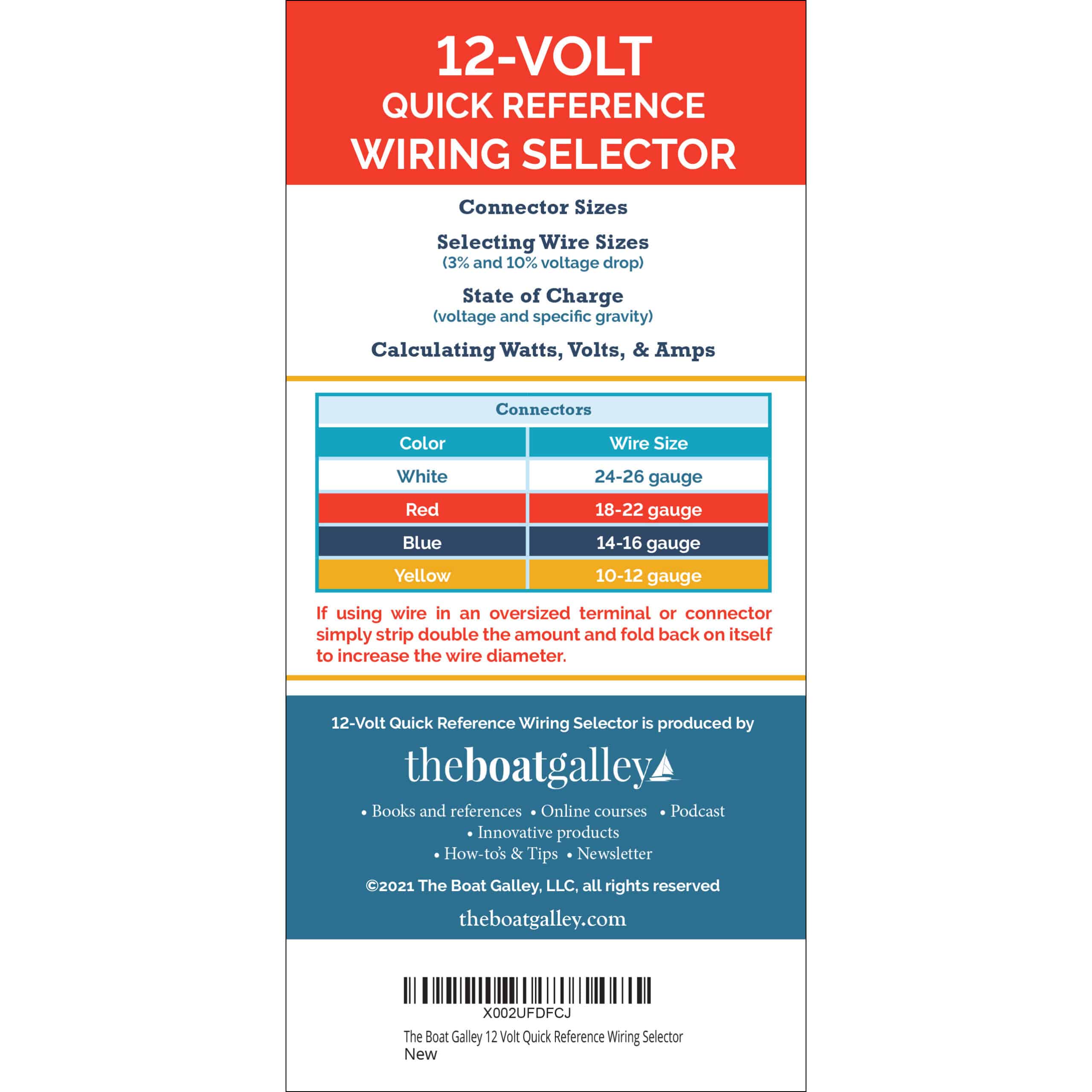

| Item | Supplier | Cost* (Nov 2021) |

|---|---|---|

| Racor 500FG turbine filter | ASAP Supplies | £224 |

| Facet 12V Fuel Pump | ASAP Supplies | £63 |

| Shut off valves x 2 | ASAP Supplies | £14 |

| Fuel hose (10mm ID), 2x 1m length | ASAP Supplies | £12 |

| Fittings and jubilee clips | ASAP Supplies | £52 |

| 10mm OD copper tube | Local chandler | £10 |

| Cable and 12V plug | RS Components | £13 |

| Switch | RS Components | £2 |

| Hour meter | RS Components | £13 |

| Junction box | RS Components | £4 |

| Waterproof case | CPC | £50 |

| £457 |

*ASAP costs include a 5% discount for membership of the Cruising Association

Why not subscribe today?

This feature appeared in the July 2022 edition of Practical Boat Owner . For more articles like this, including DIY, money-saving advice, great boat projects, expert tips and ways to improve your boat’s performance, take out a magazine subscription to Britain’s best-selling boating magazine.

Subscribe, or make a gift for someone else, and you’ll always save at least 30% compared to newsstand prices.

See the latest PBO subscription deals on magazinesdirect.com

- Vessel Selection Assist

- Pre- Purchase Guidance

- Building Your New Vessel

- Equipping Your New or Pre-Owned Vessel

- Boat Owner and Buyer Articles

- Sample Inspection Reports

- Testimonials

- Boat Buyers Gallery

- Captains’ Club

- Ready for Sea

- Refitting & Repairing Your Boat

- Vessel and Systems Inspection

- Boat Owners Gallery

- Industry Consulting

- Industry Articles

- Industry Gallery

- A Complete List of Photo Albums

- About Steve’s Photography

- Project Destinations

- Aircraft Flown

- Educational Videos

- About Steve

- Contact SDMC

- SDMC Lecture Offerings

- SDMC Webinar Lecture Series

- Seaworthy and Challenges

- Travelogues

- Feature Article

- Marine Systems Excellence eMagazine

Fuel Polishing Systems Explained

By Steve D’Antonio Copyright September 2013

Seaweed-like tendrils, similar to those shown here, are a sure sign of water contamination Among other things, polishing systems that are properly plumbed will prevent this problem.

I attend many boat shows and marine trade exhibition each year, from the Miami and Ft. Lauderdale Shows to the International Boat Builders’ Exhibition (IBEX) in Louisville, Kentucky, and the Marine Equipment Trade Show (METS) in Amsterdam, the Netherlands. At each show I encounter what seems to be an increasing variety of new and interesting products. The exhibitor’s floor and tents are a veritable gearhead’s candy store, row upon row of interesting gear in booths that are more often than not staffed by knowledgeable personnel who enthusiastically talk about the products they represent and in many cases invent and build themselves.

Fuel polishing systems have become exceptionally popular, and the space dedicated to their display seems to increase with each passing year. I delivered a lecture on the subject at IBEX a couple of years ago and the questions from the audience, mostly builders and boat yard folks, were excellent and plentiful. This demonstrated to me, however, that even the professionals are not clear on the preferred installation approaches or the differences in the available systems, and make no mistake about it, the differences are truly vast.

Plumbing is by far the most challenging aspect of any polishing system installation. It is invariably the cause of most performance problems.

The quality and effectiveness of these systems runs the gamut, from those that perform as advertised (while going easy on the hype) to those that promise the world and then some and often don’t deliver. I intentionally make it a point of engaging the folks representing the products that I encounter, asking them questions about what they do, how they work, how they should be installed etc. (I often flip my name tag over when doing so). The responses are interesting. Many representatives know their products inside out and are honest and realistic about what they could be expected to do where fuel and contamination issues were concerned. A few, however, make wild claims, often while bashing their competitors’ products, about how their systems were capable of solving all fuel ills, including cleaning the fuel as well as seriously contaminated tanks. The former should be a given, the latter is virtually impossible.

High capacity polishing systems like the one shown here, are often palletized, they include filter, high volume pump, and a control mechanism or timer, along with a vacuum gauge.

The profusion of polishing in the past decade is an indication of the need, or perceived need, for added fuel filtration. It is, however, undeniable that fuel contamination, and the problems is causes, are a very real issue for many diesel-powered vessels.

At the other end of the spectrum from high volume pumps, this prototype Lilliputian supplemental filtration system works by filtering fuel at a very low volume, albeit continuously.

Most high volume polishing systems rely on either geared, like the one shown here, or multi-chamber diaphragm pumps. The plumbing used must be of sufficient diameter to accommodate the flow rate of these pumps.

The mother of all polishing systems, centrifuges are capable of slinging water and dirt out of fuel down to a single micron, and they do so using centrifugal force rather than filter elements.

Nearly as important as the filtration itself, the display and controls enable users to operate, and monitor the polishing system, in this case remotely.

With the increase in shear volume of fuel polishing systems it’s inevitable that there will be differences. The good news is, from my perspective nearly all of them are or would be effective to some extent at removing some contamination. Beyond that, however, things get somewhat hazy. My own personal criteria for fuel polishing systems are, among other things, that they maintain not only the cleanliness of the fuel but the tank as well.

In order to work effectively, polishing system pickup and return plumbing must be plumbed to opposite ends, and always to the bottom, of a tank. In some cases, depending upon access, that plumbing may be run internally, like that shown here.

In order to do so, they must utilize a pump whose volume is significant, on the order of at least 100 gallons per hour. This pump capacity ensures meaningful movement of fuel through the tank, which is a critically important aspect of a fuel polishing system, particularly for vessels that spend much of their time at rest. Thus, capacity or volume matters when comparing fuel polishing systems.

Remember, this is just my definition, any person or manufacturer can plumb and wire a small electric fuel pump to an equally small filter and call it a polishing system, there’s no official definition. And, they can install it by “paralleling” the pick up and return plumbing to the tank’s and engine’s existing ports.

If polishing system supply and return fittings are located close together, a common installation fault, fuel will “short cycle”, moving primarily between these two fittings, rather than across the bottom of the tank.

The fuel can be filtered when the engine is not running, which could be construed as polishing. Indeed, all fuel filtration is good. If you choose a low volume polishing system, what I like to call, and not in a disparaging way, supplemental filtration, you are certainly on the right track. All filtration is good.

However, don’t expect it to perform in the same manner as a high volume system. Roughly speaking, supplemental filtration systems are most effective at cleaning the fuel rather than maintaining the cleanliness of the tank. This is strictly a function of their low volume pumping action. If the vessel is underway frequently and the fuel within the tank remains agitated, which prevents a phenomenon known as agglomeration (small suspended particles attract each other, forming larger agglomerates, which then sink to the tank bottom) and settling of heavier contaminants such as water and asphaltine, then supplemental filtration will often do a creditable job of keeping the fuel clean.

A seriously contaminated fuel tank; the material on this tank’s bottom is likely the result of years’ worth of agglomeration, a process whereby small particles suspended within the fuel attach to each other and then sink. This type of accumulation is notorious for quickly clogging filters when vessels afflicted with it enter a seaway. While it is the primary mission of a polishing system to prevent this type of buildup, polishing systems installed after it has accumulated are no match for its tar-like consistency. Contrary to the claims of some polishing system manufacturers, and dockside cleaning services, its removal is an arduous job that can only be accomplished by scooping, scrubbing and washing, a process which requires access to every baffled chamber of the tank.

If, however, the vessel remains at rest for long stretches of time, then supplemental filtration is likely to be less effective than a high volume polishing system. Additionally, a high volume polishing system should be sized and installed so it passes all of the fuel in the tanks through its filter three times in a “reasonable” amount of time. Reasonable is open to interpretation, however, my definition is eight to ten hours. Thus, a supplemental filtration system may find itself “challenged” when mated to a large tank or tanks.

Like fuel plumbing for the engine, polishing system plumbing must be robust, leak-proof and flame resistant.

In addition to the selection of the polishing or supplemental filtration systems themselves, the other hurdle frequently faced by those purchasing these systems is obtaining or ensuring proper installation. Even the best, high volume polishing system will be of little value if it’s not properly plumbed to the vessel’s fuel tanks, in a manner that takes maximum advantage of the systems flow rate. This is especially important for high volume polishing systems. In order for them to work most effectively they must be plumbed using dedicated fittings that share no part of the tank’s or engine’s/generator’s existing fuel system.

A textbook example of paralleling, sharing fuel pick up and return fittings with the vessel’s main engine. This approach severely restricts a polishing system’s capabilities, as well as potentially starving an engine of fuel, and should therefore be avoided.

This is necessary for two reasons. One, existing fuel plumbing is nearly always too small for high volume polishing pumps, polishing systems often require plumbing as large as ¾ inch inside diameter. Two, the location in the tank of existing pickup and return fittings is nearly always detrimental to the efficiency of a polishing system.

When a polishing system is plumbed to more than two tanks a manifold is typically employed.

Polishing system pick up and return fittings should be located as far apart as possible, preferably at opposite ends of the tank, ensuring maximum movement of fuel. And, the polishing system pickup should be close to the bottom of the tank, closer than the primary engine pick up, ensuring that it removes all or as much water and debris as possible.

Polishing system pick up fittings should be located at the absolutely bottom of a fuel tank. While appropriate for supplying fuel to an engine, fittings like the one shown here are not low enough for polishing system use.

Finally, where installation plumbing is concerned, the return fitting must be equipped with a drop tube. This ensures maximum turbulence at the bottom of the tank where debris invariably accumulates and it avoids aeration of the fuel, which hastens its degradation and increases the risk of erratic engine operation.

Where supplemental filtration is concerned, large diameter plumbing is not an issue, however, paralleling filtration with engine fuel supply can lead to problems and, the fuel can short cycle between the pick up and the return within the tank, minimizing how much fuel is actually filtered.

While a polishing system is no substitute for conventional primary and secondary fuel filters, when one is installed and used regularly, replacement intervals for these filters are nearly always extended.

The elephant in the room that I haven’t addressed is expense. High volume polishing systems that are properly plumbed to fuel tanks in the manner described are nearly always expensive affairs, typically in excess of $10,000 installed (often less if carried out during the vessel’s construction), while supplemental filtration systems are often a tenth of that. If this simply isn’t in your budget, or if you have a smaller tank or if your vessel is used frequently (keeping the fuel agitated and contamination in suspension), you may opt for the considerably less expensive but possibly less effective supplemental filtration route. Remember, when it comes to diesel fuel, all filtration is good, and the more you have the better. Not every vessel needs a polishing system. More importantly, however, if you do choose to install one, make certain you understand what it can, and cannot be expected to do.

For more information on the services provided by Steve D’Antonio Marine Consulting, Inc. please e mail Steve at [email protected] or call 804-776-0981

You cannot copy content of this page

Get the leading diesel fuel polisher you need at the best price on the market!

Fuel Polishing Systems for any budget. 400 GPH to 1200 GPH We offer Equipment Financing and Lease options.

Cleaning the stored diesel fuel you use for standby power must be tested and polished on an ongoing basis. Dieselcraft can provide you with the tools you need for commercial generators, large marine diesel engines, and more. We can set you up with a portable fuel polishing machine as well as a maintenance service. You can make your diesel fuel system cleaner by taking contacting us now.

Portable Fuel Polishing with Filter-less Technology

It’s just about impossible to prevent all water from working its way into diesel fuel. But the key is to create conditions that will keep the amount of water in diesel fuel to a minimum. Dieselcraft portable fuel polishing systems can remove more than 99% of the water and solids in your diesel fuel tanks with out a filter and reverse your problems.

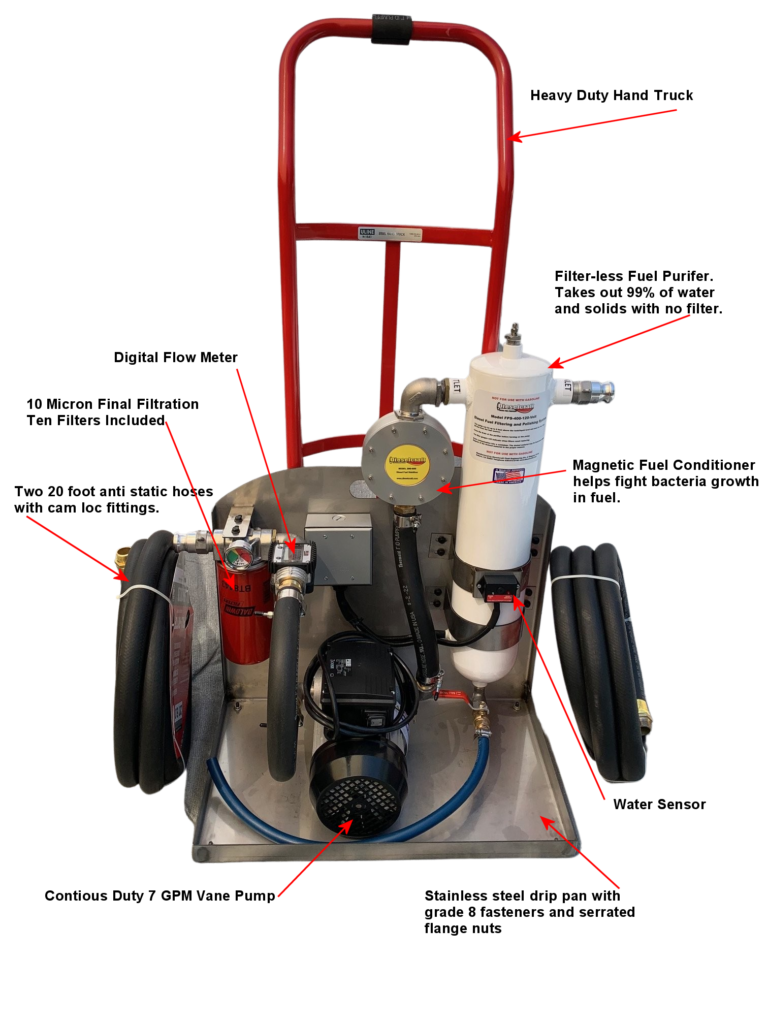

The FPS-400

A modular tank cleaning and fuel polishing system designed for the transfer and/or re-circulating of diesel fuel in storage tanks, boats, generators and trucks.The system utilizes a 115 volt, 400 gallon per hour continuous duty pump in conjunction with a Dieselcraft Model 200- 900 magnetic fuel conditioner to reduce bacterial growth, a 5×24 maintenance free filter-less fuel water separator/purifier and plus a 10 micron spin on filter.

A modular tank cleaning and fuel polishing system designed for the transfer and/or re-circulating of diesel fuel in storage tanks, boats, generators and trucks.

The system utilizes a 115 volt, 30 gallon per minute continuous duty pump delivering over 1,200 gallons per hour in conjunction with a Dieselcraft Model 200- 900 magnetic fuel conditioner to reduce bacterial growth, a 8×32 maintenance free filter-less fuel water separator/purifier and plus two 10 micron spin on filters.

This is the perfect system for the larger sized fuel polishing jobs.

NEW! FSP-30 Rolling Skid with Pre-filter.

Diesel Fuel Maintenance Services

Contact Warren van Dongen [email protected]

Our fuel maintenance services include everything from fuel sampling and fuel polishing-filtration to assure the fuel meets ASTM standards for stored fuel. We work closely with those Commercial Companies, IT Data Centers, Hospital and Municipalities who have long term stored fuel and need to comply with current standards. We can create the proper service package for you and your company to ensure your diesel fuel is always in spec and clean so no issue arise when that emergency happens.

Ask Us Questions

- Full Name *

- Company (if applicable)

- Quote Request

- Need a Call Back

- Products you are interested in?

- Comments and Notes

- Phone This field is for validation purposes and should be left unchanged.

Contact Information

Contact us across the USA and Canada plus Australia.

Get a Quote on West Coast Call 530-613-2150 Text 530-613-2150 Email [email protected]

Get a Quote in Eastern States Call 772-215-8087 Text 772-215-8087 Email [email protected]

Get a Quote in Gulf Coast States Call 337-277-5417 Text 337-277-5417 Email [email protected]

Get a Quote in Central Canada Call: 800-665-2494 Email: [email protected]

Get a Quote in Atlantic Canada Call: 902-616-8100 Email: [email protected]

Get a Quote in Australia Call: 61-2-95334433 Email: [email protected]

Recent Posts

- How to Read and Interpret a Fuel Test Report from a Laboratory

- Diesel fuel begins to degrade in less than 30 days in your storage tanks.

- Diesel fuel testing is essential.

- What is Diesel Fuel Management?

- Understanding the Impact of Contaminants on Engine Performance

Recent Comments

- August 2022

- January 2022

- December 2021

- August 2021

- December 2020

- November 2019

- August 2019

- January 2019

- December 2018

- November 2018

- September 2018

- August 2018

- Diesel Engine

- Diesel Fuel Problems

- Fuel Tank Cleaners

- Fuel Test Kits

- Fuel Testing Services

- Uncategorized

- Entries feed

- Comments feed

- WordPress.org

Dieselcraft

- Forums New posts Unanswered threads Register Top Posts Email

- What's new New posts New Posts (legacy) Latest activity New media

- Media New media New comments

- Boat Info Downloads Weekly Quiz Topic FAQ 10000boatnames.com

- Classifieds Sell Your Boat Used Gear for Sale

- Parts General Marine Parts Hunter Beneteau Catalina MacGregor Oday

- Help Terms of Use Monday Mail Subscribe Monday Mail Unsubscribe

DIY Fuel Polishing System

- Thread starter jmce1587

- Start date Oct 27, 2021

- Forums for All Owners

- Ask All Sailors

Amazon.com: Racor Polisher Diesel 10M 12V/24V : Automotive

I would suggest, you save your money or use it to make access into your fuel tank, get spotlessly clean. Clean, the pick up tube and your fuel polishing problems will be over. Racor filters are very expensive if you really feel you must build the system, use two and three in line oil tank fuel filters like what are used on residential fuel oil tanks (cartridge style even) they are allot cheaper.

That's an expensive system, you can build one yourself for much less. This thread has lots of good information on whether it's worth having one: Fuel Polishing

Ralph Johnstone

A cheaper approach might be to have the tank professionally polished (check the cost of pressure washing) and then chemically take care of it. Mine is 22 Y.O. and nary a speck of dirt that I can see through the inspection hole.

There is little advantage to a polishing system if your tank(s) are not spotlessly clean. You already have (or should have) at least 2 filters in your fuel line and the vast majority of the diesel pumped to the engine returns to the tank cleaned. Our tank (170 gal) with several baffles is rather dirty and we use a Racor as our primary filter. This is changed frequently. The secondary is rarely all that dirty when we change it, after about 6 Racor filter changes.

SBO Weather and Forecasting Forum Jim & John

jmce1587 said: I want to be able to polish my fuel and am considering this Racor system. Click to expand

Fuel polishing system is a circulating pump, a particle filter, a water separator (often combined) and a timer. I made my own after creating an access hatch and cleaning the tank. Still going strong, no water, no gunk in the polishing filters/separators.

jssailem said: When I have a flash of an idea, especially in the evening after a glass or two of wine, I try to put the credit card away and let the idea rest till after my morning coffee. Click to expand

I made a system and it is more for polishing the fuel going in the tank to make sure it is clean than to clean old fuel. I made an L shaped plywood board with a Racor S12 or something filter, a cube type 12V pump and a switch. A few hoses and some fittings and it was probably around a hundred bucks. You can get low cost filters at tractor supply for diesel fuel, doesn;t have to be "marine". The same pump is useful to pump out the tank for cleaning and inspection into five gallon jugs. My tank is 23 gallons so four jugs will empty an almost full tank. 500+ dollars is ridiculous unless you plan to go into business. I buy my fuel in five gallon jugs, run it through the filter system into a known clean jug then put it in the boat. To get rid of old fuel offer it up to a fishing boat with diesel motors. Those guys use a lot of fuel and love it for free.

There was a filter container from the 70's, that let you put a roll of toilet paper in the container as a filter medium. Wonder how that might work in this project. Looked pretty simple in design and inexpensive for a filter medium.

jssailem said: There was a filter container from the 70's, that let you put a roll of toilet paper in the container as a filter medium. Wonder how that might work in this project. Looked pretty simple in design and inexpensive for a filter medium. Click to expand

senang said: Fuel polishing system is a circulating pump, a particle filter, a water separator (often combined) and a timer. I made my own after creating an access hatch and cleaning the tank. Still going strong, no water, no gunk in the polishing filters/separators. Click to expand

I am sailing in the med. You can always get the bottom of the storage tank unknowing to you and only find out the problem created when the weather gets rough stirring up the tank contents. Polishing is my solution to this problem. Some will tell to use a funnel with filter but this is not a practical solution in the med in summer when you are lining up with many other boats for a fill up.

Hi Jerry, never had a need to polish our fuel; always clean as mentioned in a previous post, since most of the filtered fuel is returned to the tank for further use. I replace our filters after a couple hundred hours or every other season. even then not that dirty and a smidgeon of water. Both our filters (Racor primary, NAPA secondary) are ten micron, which is more than adequate to protect your engine. You can go less, but...

New Universal Refiner by John Frantz Oil Filter Kit

jmce1587 said: Has anyone built their own portable fuel polishing system? What’s involved and things to consider? I want to be able to polish my fuel and am considering this Racor system. Also not sure what filtration level to polish to 10, 5, or 2? Amazon.com: Racor Polisher Diesel 10M 12V/24V : Automotive Buy Racor Polisher Diesel 10M 12V/24V: Fuel & Water Separators - Amazon.com ✓ FREE DELIVERY possible on eligible purchases www.amazon.com Any/ all suggestions welcome. Thanks Click to expand

Barnacle Bill

I own one of those Racor systems you found on Amazon. It was easy to use and worked quite well. It is spendy as are the filters.

- This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register. By continuing to use this site, you are consenting to our use of cookies. Accept Learn more…

- Skip to main content

- Skip to primary sidebar

- Skip to footer

The Boat Galley

making boat life better

DIY Fuel Polishing

Published on July 26, 2020 ; last updated on October 31, 2023 by Carolyn Shearlock

Why Should You Polish Your Fuel?

Fuel polishing is a way to get water, microbes and any other contamination out of fuel before it harms or stalls an engine.

Hot, humid weather will allow condensation to form in a fuel tank, particularly if it’s only partially full. Condensation in a fuel tank allows water to get into the fuel. Various microbes love that water and will multiply in it at the bottom of the tank. While a biocide can help, it can only do so much. And you’ll still have sludge at the bottom of the tank from all the now-dead microbes.

Why worry about water, sludgy microbes and debris? The immediate problem is that your engine will die — it won’t run on water and debris can block the flow of fuel. That’s bad enough if it happens just as you’re entering a tricky place, say a marina or going through a bridge. But the even bigger problem is that both water and debris can cause thousands of dollars of damage to your engine.

IMPORTANT NOTE: Even with a Racor filter on your fuel line, if there is just too much water in the fuel, it can get past the filter on the smaller Racors that most recreational boaters have — large Racor systems sometimes do have a check valve that stops the flow if the water reservoir is full. Always check the sight bowl in your Racor for water at the end of a day; check it several times a day if motoring a long time in order to catch a problem before your engine is damaged. Sludge and debris can clog a Racor in mere hours, again causing your engine to just stop.

Fuel polishing is pumping all the fuel out of your fuel tank(s), running it through a filter to remove water and debris and putting it back in the tank. Some professional services also clean the tank while it’s empty.

When Is Fuel Polishing Needed?

Your fuel will likely need polishing:

- When your boat has sat for a while in a humid climate (particularly with day/night temperature swings causing heavy dew or fog, both indicators that condensation is likely in the tank)

- If you buy a used boat that hasn’t been used recently.

- Should you discover that the fuel cap was loose and water/dirt may have entered the tank.

- If someone confuses the water and fuel fills and putting water in the fuel. Yes, this happens.

- If you get a load of “bad fuel.”

- Any time you discover an abnormal amount of water or debris in your Racor filter.

- Before going out in “boisterous” conditions if the fuel hasn’t been polished recently — any water and debris that has settled to the bottom of the tank will be stirred up with the motion of the boat.

In many places, there are commercial fuel polishing services. But it always seems that when we need our fuel cleaned, there are none available, they’re prohibitively expensive, or there’s a long wait for service. Hence doing it ourselves (we know some people who have fitted an electrical fuel pump and filtering loop onto the fuel system in their boat — that’s also an option for doing it yourself, albeit a more expensive one).

Tools Needed for DIY Fuel Polishing

It costs about $100 to get the tools needed to polish fuel our way, assuming you already have a drill (or use an electric pump) and have or borrow sufficient jerry cans.

To polish your fuel yourself, you need:

- 12 volt Diesel Transfer Pump with Alligator Clips on Amazon — we do not have this but friends do and are happy with it. The big thing is having power available (you can replace the alligator clips with a cigarette lighter style plug if you have a handy outlet, too).

- Sufficient containers to hold the contents of one fuel tank. Jerry cans are great and you may be able to borrow some empty ones from friends, too. You can also use 5-gallon buckets lined with clean trash bags. Whatever you use, you have to have sufficient containers to be able to remove all of the fuel from one tank at a time. You can, of course, transfer the fuel from one tank through the filter and into another if you have an empty tank (you may want to clean the empty tank first).

- Mr. Funnel sold on Amazon — this size works well with transferring from jerry cans. If you want a larger filter that can also be used when filling at fuel docks, this size is better — but it’s much larger to store!

- Shaker siphon on Amazon

- Container to put any water caught in the filter into, for transport to an appropriate disposal site.

- Rags , paper towels or blue shop towels. To catch spills as necessary.

How to Polish Fuel Yourself

- Pump all the fuel from one tank into jerry cans or other containers. You can use the water/sediment filter as you’re filling the containers or you can filter it as it goes back into the tank. (You can filter it on both transfers if you fear serious contamination.)

- Wiggle the pickup tube around as much as you can to make sure you’ve gotten as much fuel out as possible. If the boat is in the water, have anyone else on board move so that one part of the tank is lowest and you’ll get the most.

- If you filter the fuel coming out and find a lot of water or sediment, it’s a good idea to go ahead and clean the tank before you refill it. How you do this depends on your tank configuration . . . maybe by wiping out the inside through an inspection port (how we did it on our Tayana 37). On our current boat, the only way to do it is to remove the tank then remove the pickup tube from the tank, then go through that hole with a rag on a stick.

- If you filtered the fuel coming out of the tank, you can simply use the shaker siphon and put the fuel directly into the tank now. Otherwise, put the funnel filter into the fill hole and use the shaker siphon to put the fuel into the funnel filter and filter the fuel as it goes into the tank. Dave finds it easier to filter at this point, but it means that if he finds lots of water or gunk and decides he needs to clean the tank, he has to pump the fuel back out of the tank again to do so.

- Whenever you are filtering the fuel, if the filter really slows down, check it for both sediment and water. Clean the filter if necessary. Pour any water into the container for this purpose and dispose of it properly.

- Repeat for any other fuel tanks.

- Calculate Your Boat Fuel Range

- Find a Fuel Problem on a Boat

- How to Use a Shaker Siphon to Fuel Your Boat

And check out our other courses and products

Find this helpful? Share and save:

- Facebook 549

- Pinterest 2.3K

Reader Interactions

Pamela Dakin Harwood says

October 23, 2015 at 1:26 pm

It seemed that every year we would have a problem with “stuff” in the fuel of my husband’s family’s 28′ lobster boat, so with Katie Mack (our soon to be liveaboard Bridge Deck Cruiser), he has designed and installed a continuous fuel polishing system.

The Boat Galley says

October 23, 2015 at 1:52 pm

I know of several people who have done something like that. Great!

October 23, 2015 at 3:20 pm

Can’t imagine that sailors need anything this complicated, so Dave’s solution is just right, but with only one engine, our powerboat needs to have clean fuel — always!

October 23, 2015 at 5:51 pm

Similar . . . but no, not as sophisticated.

Georgi Wellington says

October 23, 2015 at 7:01 pm

Dennis Wellington

Jonathan says

October 23, 2015 at 4:00 pm

If a tank has a bad case of sludge, the only way to get it out is by hand through an inspection port. That is why so many boats who think they have clean fuel tank run into fuel problems when the tanks get a good shaking. So keep a bunch of filters handy if you are going offshore, and check the sight bowl every hour if you are running the engine in bad conditions. My $.02

October 27, 2015 at 7:38 am

Great article (as always!). I have a total noob question – in step 5, how do I clean the filter? Just wipe it with a rag? Sorry – I’m new to all this but love the idea of being able to do it myself.

Carolyn Shearlock says

October 27, 2015 at 7:40 am

It’ll come with directions on how to clean it, but yes, basically you dump the water out and wipe it off with a rag to get any “gunk” off.

Chris in Oregon says

October 29, 2015 at 12:21 pm

Timing is everything… I just received today from Northern Tool a 12v diesel fuel transferring pump. Bought to do two things, #1 being able to refuel boat from jerry cans without having to hoist them on deck from the dingy and #2 adding a filter to allow pump to be a fuel polisher. I looked at DYI and cost wise it was about a break even to just get it from them.

Paul Johnson says

October 29, 2015 at 12:46 pm

Hi Boat Galley, Have just read your article on fuel polishing with great interest. Here in the UK we have a problem with Diesel Bug, this grows in the interface between fuel and water and causes the black sludge in your fuel tank. A recent article in Practical Boat Owner they talked about a product called ‘Fuel Guard’ and their web site http://www.fuel-guard.co.uk shows the product in action, it’s a very effective demonstration, and all you need to clean the filter is clean diesel and a soft paint brush, the filter lasts a lifetime. I bought one for my boat and it’s been very impressive, I’m conviced the engine is running better as well!

October 29, 2015 at 1:52 pm

Thanks for the info!

Dawn Read says

September 10, 2016 at 12:36 pm

This is good! Thanks! Lucky, check it!!!

Rick Garvin says

September 10, 2016 at 1:12 pm

Great article! Christine, we need to by a Mr. Funnel.

Molly Brown says

September 10, 2016 at 2:06 pm

Thanks for the great ideas. We have had dingy motor problems from bad gas and needed a good filter.

Eric Meury says

September 10, 2016 at 4:32 pm

I make sure to read all your posts and have you book. I would not consider what you are doing as polishing the fuel, rather re filtering to to get the crude and water out. This method does nothing for the actual chemical make up of the fuel. The link below is the system we have on our boat. This pictures are our boat. We polish the fuel constantly while the engine is running and we polish when ever we fill up. Even in the states we end up removing water and some crud. Oh one other thing. Whenever my main engine isn’t going to be used for a week or more i also do a fresh water flush using the cockpit shower hose. This way no salt water sits in my exchange or exhaust system. http://www.properformancemarine.com/service7.htm

September 10, 2016 at 5:46 pm

I’m not sure what “polishing” fuel means to you. I am familiar with it as “fine filtering to remove contaminants and water” — which is exactly what this does. Admittedly it’s not as sophisticated as yours and I’m sure ours doesn’t filter quite as finely or as completely. But we have a much smaller boat — there’s nowhere to put a system such as yours in!

September 10, 2016 at 5:48 pm

a copy and paste – fuel polishing uses centrifuges, coalescers, and – yes – filters to remove non-combustible particulate matter (sand, dust, cigarette wrappers, lady bugs, and – our personal record – a dead rat) from fuel. In short, everything that wasn’t really supposed to be there in the first place.

Because water is heavier than fuel, the centrifuges and coalescers do a good job of removing that, too. We then use water blocking filters to pick up the last little bit of suspended – or “entrained” – water available.

The primary difference between fuel polishing and fuel filtration is that fuel polishing acknowledges that fuel itself can degrade and cause solids. Fuel filters will simply pull the solids out because they plug up filters whereas fuel polishers break down the combustible solids so that the fuel stays within the industry specifications.

http://www.properformancemarine.com/service7.htm

December 15, 2017 at 12:54 am

G’day, my boat takes a ton of fuel. Gonna be a job and a half if I bother. Love folks ideas and comments.. Can only make one wiser.

Steve Hardison says

March 15, 2018 at 5:24 pm

“Large Racor systems sometimes do have a check valve that stops the flow if the water reservoir is full.” — Sorry,not true. The ball floats on fuel or water. It is pushed out of the way when fuel is flowing. Its purpose is to check the fuel from flowing back to the tank when flow stops. If the Racor housing fills with water, water will be forced through the media. The best defense against water is a new filter element. As filters clog, they don’t stop water as well as they did when clean. It’s cheap insurance to just change the filter when vacuum reaches 4 to 6 inches Hg above the starting vacuum. Going up to 15 inches Hg vacuum risks poor water removal performance.

Jan Hansen says

July 7, 2018 at 12:28 pm

One question, I have made a similar set up, using a pump with metal impellers, rather than rubber. I have a Racor 500 w clear bowl, I am waiting for the manometer, and the drain cock rather than the unscrewable nut. I have no idea, how bad my tanks are ( 2nd hand vessel from the 70s ) I would have to destroy a fair bit of the interior, to be able to access anything but the base of the tanks , as they are square, and are ” On End ” rather than ” Lying Down ”

My plan, was to run both hoses, into the same tank ? One hose sucking up, and the other agitating the bottom, with clean returning fuel ? I would rather spend a few dollars on filter elements, than have to have a carpenter cut away my interior ?

July 7, 2018 at 12:30 pm

Sorry, bases are square, the tanks themselves are oblongs, stood on end

July 8, 2018 at 10:23 am

If I understand correctly, you just want to use your Racor as a fuel polisher. Sure, some people do that. It works but if you have any serious contamination you’ll go through a bunch of filters.

July 9, 2018 at 6:47 am

Yes, I do not have anything, to empty the tanks into, but most responses seem to state exactly that. As said, the way the boat is built, trying to access the tanks, to cut inspection holes, is beyond the cost of destruction & re build of the interior. On the other hand, I would have to buy a 100 gal tank, to empty the tanks into, one at a time, then try & re sell the tank, since there is no room to keep it on board. So, my idea ,as said, is to run the pump & filter, with both hoses in the same tank. Yes, I do understand , it will probably use a lot of filters, but Im assuming it will be better than the alternative. Ok, Ill get on , with the job, Im still waiting for the manometer and tap, but, once i get started, I will post the results here. Of course , I do wish the tanks had drainable sludge pots, in the base, but ,sadly no. Cheers

October 23, 2019 at 9:16 pm

I’ve used basically the same technique as Jan suggests… just recirculating as I stirred up the muck in the bottom. I used cheap filters until the fuel looked better (went through about 10), then switched to a Racor 30, then 10 micron. I did have access to the tank via the fuel sender port, which is where I inserted the suction tube. I also have one of those cheap scope cameras that I used for inspection… pretty handy. Like Jan says, rig something on the end of the pickup tube that will weight it down and stir up the bottom. I used a 10 gpm diesel transfer pump, which stirred the fuel up pretty well as it re-entered the tank… just have to keep on it till it’s clean!

jan Hansen says

July 27, 2018 at 10:50 am

Well, so far, so good, Ive used 4 filters so far and picked up loads of sludge & bits, just bought another 10 filters today, and will carry on. So far Ive only worked on 1 tank, with a metal bar whipped to the fuel hose & small polythene funnel, cut down and ground slots into, so it sits on the bottom with holes enough to allow crud to be sucked up. also, the returning fuel, agitates the bottom so more crud crud is stirred up. So far, no sign of water , in the tank Im working on, but lifting the suction hose, and bouncing it off the bottom, certainly fills the clear bowl with a black cloud of bits. I guess the tank spigot, is raised above the bottom, because getting that suction hose to the bottom, jeez the filth that the filters get filled with is awesome. So far, no sign of any water, in the bottom, just black sludge. So Far.. So Good.

JAN HANSEN says

July 29, 2018 at 12:38 pm

Well, between the 2 x 100 Imp Gall tanks, it took 11 filters, to clean it up and get water out. Having the manometer on top, is worth the extra cost, because it removes all guesswork. Once it gets well into the red, its time to change filters. I was going to post a piccy of the system I built on a cheap shopping trolley frame, but cannot see how. Cheers.

Nasty Chicken says

May 16, 2019 at 9:00 pm

Nice work Jan, I trust the clean tanks made a huge difference!

May 18, 2019 at 7:05 am

I have not done any rolly polly passages, as yet, but, there is certainly a load less sludge & bits, in the tanks. So if I do get into rough stuff, im assuming my fuel filters , will be ok. Thanks !

June 4, 2020 at 1:07 pm

I have an IO with at 16 gal. tank. It has been setting for 25 or so years. There is a thick sludge in the bottom of the tank. How can I get that sludge out of the tank to clean it. Will fresh gas dilute the sludge so that I can pour it out? or What else can I use to clean out the sledge? I’m restoring the boat and want a clean tank. Art from Virginia – fresh water boater.

June 5, 2020 at 8:33 am

You will probably need to cut an inspection port into the top of the tank so that you can get your arm in there to really clean it out. Fresh fuel is a bit of a solvent, but you’re going to have to do some work if it’s really sludgy.

Robert Hogward says

November 7, 2020 at 8:19 pm

So, what about draining gas from Boat fuel tank? I concerned about some residue buildup in my fuel tank. And can draining gas from my fuel tank be hazardous? Many thanks!

Leave a Reply Cancel reply

Your email address will not be published. Required fields are marked *

Each week you’ll get:

• Tips from Carolyn • New articles & podcasts • Popular articles you may have missed • Totally FREE – one email a week

SUBSCRIBE NOW