Berthon Winter Collection

Latest issue

August 2024

In the August 2024 issue of Yachting World magazine: News Few finish a tempestuous Round The Island Race European rules are eased for cruising to France and Greece Olympic sailing…

Yachting World

- Digital Edition

Pip Hare’s sailing masterclass: How to make the most of a water ballast system

- May 21, 2020

Water ballast is no longer the preserve of ocean racing yachts, it can now be found on performance cruisers and smaller racing boats. Pip Hare shares her top tips for using it

The JPK 1030 features transfer pipe and inspection hatches. Photo: Jean-Marie Lio

No two water ballast systems seem to be the same, but the principles for use and troubleshooting remain the same. Here are some guidelines for success.

Filling ballast

The ballast is filled via a scoop in the bottom of the boat, which is like a ‘reverse snorkel’. The snorkel is pushed down with the hole forward to fill the ballast, when the hole is facing aft the tanks can empty. To seal the system the scoop is retracted into the hull, leaving a flush finish.

A single scoop will be situated on the centreline, while twin scoops are placed outboard, so the leeward scoop must always be used for filling. When the scoop is pushed down, providing water is moving over the hull it will start to fire water into the boat. Filling can be achieved through continued forwards motion although this can take a lot of time so a pump is often used to accelerate the process.

Before pushing down the scoop, ensure all valves are in the correct position – this takes concentration if you’re not familiar with the system. Check:

- Valve to leeward scoop is open.

- Valves to leeward tanks are shut.

- Valves to water pump is open.

- Valves out of water pump are either directing towards windward tanks, or open on windward and closed on the leeward side.

- Correct windward tanks are selected – you can fill multiple tanks at the same time.

Once the valves are in the correct position push the scoop down then turn on the ballast pump. Once water is overflowing from the breathers on deck, first close the tank valves, then shut off the pump and retract the scoop.

Article continues below…

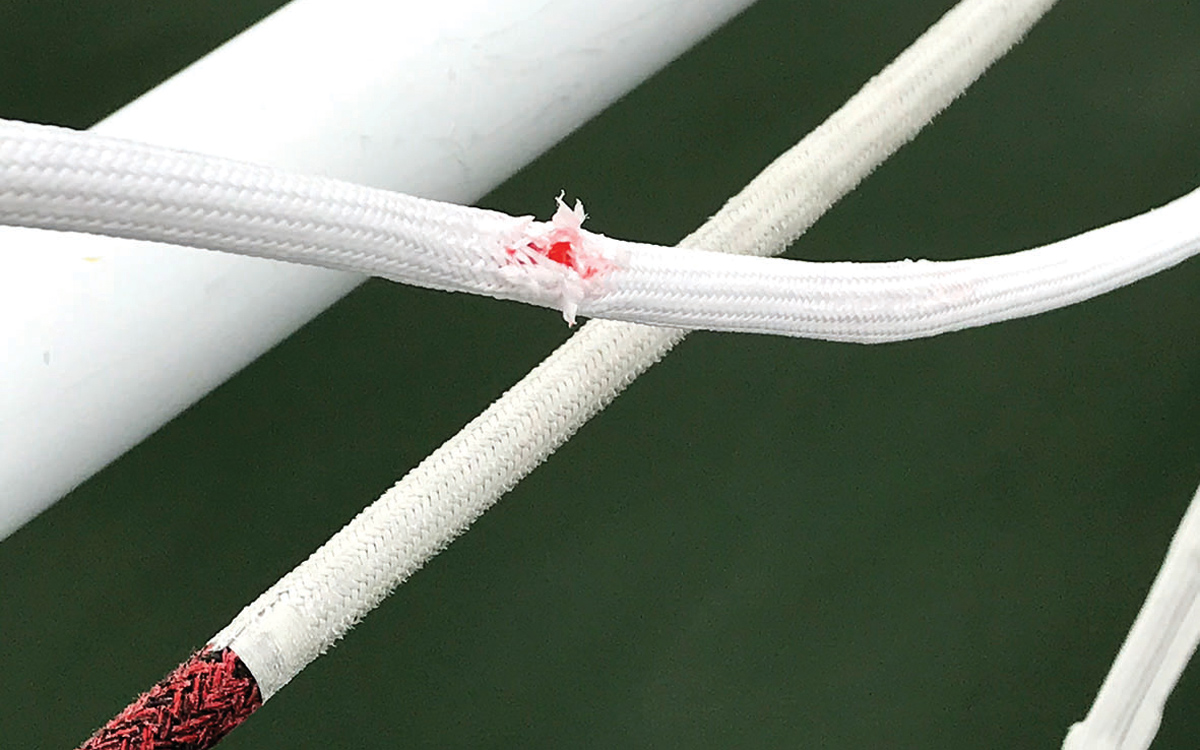

Pip Hare’s top tips for preventing chafe on lines, sails and hardware

Chafe on sails and ropes is something we should expect as part of the general wear and tear on passage,…

Expert sailing tips: Mike Broughton on racing fast and wet boats

There’s spray everywhere and your eyes are stinging. You are planing downwind in 20 knots of wind averaging 18 knots…

If you’ve been running the ballast pump but the tanks are not filling then look for air in the system. Airlocks are a common problem with a pump and can be tricky to remove. Start by identifying where the lock is; transparent pipes are helpful. Then your objective is to flood that part of the pipe.

Every system will be different but things that can work include turning off the pump, rotating the scoop aft to empty for a few seconds, then face it forward and turn on the pump again. Or try changing the angle of heel to flatten the boat momentarily.

If all else fails, changing tack but leaving whatever ballast you have on the same side might shift the air. Tack, then tack back and try the whole process again.

Transferring ballast

Any manoeuvre involving transferring ballast is going to take time and it’s important to factor this into your planning and make sure you have enough ‘runway’ to complete your manoeuvre. For example, if you know it takes 140 seconds to drop the ballast and you’re sailing upwind at eight knots you’ll need one third of a mile to complete the tack from the moment you open the valves.

Use the time it takes for the ballast to transfer to get set up on deck for tacking and to move the stack to leeward (if allowed). Remember the trim of the boat will change while the ballast drops, so ease the mainsheet or traveller to control excess heel and feather the boat into gusts.

The process for transferring ballast is simple:

- Check scoops are retracted and valves closed.

- Open leeward tank valves, open transfer valves, open windward tank valves.

- Once all water has transferred, close all valves.

The most common mistake is to close the valves and tack before all the water has run down. Sight glasses can help but they often don’t go to the bottom of the tank. Try putting your ear close to the windward transfer pipe, you should be able to hear water running through; if there’s no sound then the tank is empty. Water will rush out of the deck breathers on the leeward side but this may happen before the windward side is empty.

Always check the leeward side after a manoeuvre and empty out any water that’s left. Expect to top up the windward side over time.

Deck-mounted control rods can open or close the ballast transfer valves. Photo: Jean-Marie Liot

Dropping the ballast

There are no tricks to emptying the ballast, other than adding a little extra heel towards the end of the process. The routine is:

- Push the leeward scoop down and turn it to face aft.

- Double check leeward tank valves are closed.

- Select the tank you wish to empty and open all valves between that tank and the scoop.

- When finished close the valves and retract the scoop.

Management and maintenance tips

- Put luminous tape on the scoops so you can easily see which way they’re facing in the dark.

- Check inspection hatches and seals regularly. These hatches are a constant pain and expect them to leak. If going on a longer voyage, then take plenty of spare hatch seals and a couple of spare hatches.

- Try very hard not to step on ballast pipes or valves.

- Check both tank levels regularly. It’s not uncommon to lose water from the windward tank or for the leeward tank to start to fill over time.

- Check all valves, particularly gate valves, are closing fully and also check the leeward deck breathers are not letting water into the tanks – which can happen if sailing with the rail constantly underwater or if the breathers are damaged.

First published in the May 2020 edition of Yachting World.

- Types of Sailboats

- Parts of a Sailboat

- Cruising Boats

- Small Sailboats

- Design Basics

- Sailboats under 30'

- Sailboats 30'-35

- Sailboats 35'-40'

- Sailboats 40'-45'

- Sailboats 45'-50'

- Sailboats 50'-55'

- Sailboats over 55'

- Masts & Spars

- Knots, Bends & Hitches

- The 12v Energy Equation

- Electronics & Instrumentation

- Build Your Own Boat

- Buying a Used Boat

- Choosing Accessories

- Living on a Boat

- Cruising Offshore

- Sailing in the Caribbean

- Anchoring Skills

- Sailing Authors & Their Writings

- Mary's Journal

- Nautical Terms

- Cruising Sailboats for Sale

- List your Boat for Sale Here!

- Used Sailing Equipment for Sale

- Sell Your Unwanted Gear

- Sailing eBooks: Download them here!

- Your Sailboats

- Your Sailing Stories

- Your Fishing Stories

- Advertising

- What's New?

- Chartering a Sailboat

- Water Ballast System

Why a Water Ballast System is Worth Thinking About

A water ballast system in a cruising boat? Not a concept the traditionalists are likely to accept unreservedly. But providing the boat isn't dependent on this for stability it can be very beneficial in a seaway.

Such a water ballast system was part of the design philosophy when we built our cruising boat Alacazam , where it just supplements the permanent ballast in the keel bulb providing additional weight to windward when required.

The water is carried in two tanks on each side at the extremity of the waterline beam, each capable of being independently filled and drained by two 12v electric pumps. This is well below the point of maximum beam, but provides substantial benefits.

The Benefits of a Water Ballast System

- the boat's Centre of Gravity is no longer on the centreline, but is transferred outboard;

- as the boat heels, the righting moment increases due to the extended horizontal distance between the centre of buoyancy of the hull, and the centre of gravity of the water ballast;

- the Roll Moment of Inertia is significantly increased in terms of both pitch and roll;

- if caught with the water ballast on the wrong tack, the converse of the above applies such that the heel to leeward is not dramatically affected.

Freshwater or Seawater Water Ballast?

Initially the cruising man in me was reluctant to forego the increased freshwater capacity that the ballast tanks could provide, so they were used to supplement the standard water tanks located close to, and either side of, the centreline.

However, after lugging over 1,000lbs of this additional water all the way across the Atlantic without using any of it, I converted it to a seawater system.

Now I can get rid of it and replace it as required, and think of it as adjustable displacement . Tacking is done by opening a couple of simple valves and switching on the appropriate transfer pump. The boat's then tacked in the normal way, and then when the transfer is complete, the valves are closed and the pump's switched off.

Hard on the wind, with both windward tanks full, Alacazam heels about 6 degrees less for the same sail area and wind strength than she otherwise would, and sails quicker as a consequence. The concentration of outboard weight in the centre section of the boat noticeably improves the fore-and-aft stability, and coupled with less heel, reduces pitch and roll appreciably, the increased displacement making the boat generally more comfortable.

As the wind moves aft, the forward tank is drained and when well off the wind both tanks are drained. Of course in a short-tacking situation, the valve turning and pump switching involved in swapping the water from one side to the other requires a lot more rushing about that I'm accustomed to, so we only use the water ballast system on long offshore tacks.

The downside is that the tanks and the plumbing take up space that could otherwise be used for stowage, but there's no doubt that a moderate degree of water ballast in a light-ish displacement cruising yacht can improve both her performance and crew comfort.

Water Ballast: A Few FAQs...

What is a water ballast system?

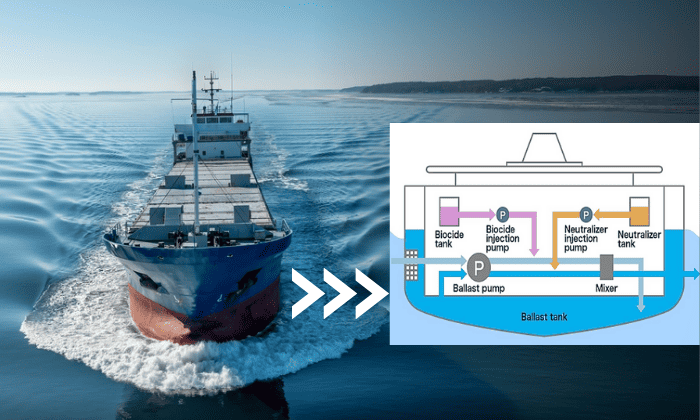

A water ballast system is a device that allows a sailboat to fill or empty tanks with seawater to adjust its stability, trim, and performance. The water ballast can be transferred from one side of the boat to the other, or from the bow to the stern, depending on the sailing conditions.

How does a water ballast system work?

A water ballast system works by using scoops, valves, pumps, and tanks to control the flow of water in and out of the boat. The scoops are openings in the hull that can be lowered or raised to capture or release water. The valves are switches that direct the water to the desired tanks. The pumps are devices that speed up the filling or emptying process. The tanks are containers that store the water ballast.

What are the benefits of a water ballast system?

A water ballast system can provide several benefits for a sailboat, such as:

- Increasing stability by lowering the centre of gravity and reducing the angle of heel;

- Improving performance by optimizing the sail area and reducing the wetted surface;

- Enhancing comfort by smoothing the motion and reducing the rolling;

- Saving space and cost by eliminating the need for fixed ballast.

What are the drawbacks of a water ballast system?

A water ballast system can also have some drawbacks for a sailboat, such as:

- Taking up precious room on board that could be used for storage or accommodation;

- Increasing complexity and maintenance costs due to the additional equipment and plumbing;

- Creating potential environmental issues by spreading invasive species or pollutants through the water exchange;

- Losing effectiveness at low speeds or when sailing upwind due to the reduced water pressure on the scoops.

How much water ballast do I need for my sailboat?

The amount of water ballast needed for a sailboat depends on several factors, such as the size, shape, and design of the hull, the weight and distribution of the fixed ballast, the rig and sail plan, and the sailing conditions. There is no simple formula to calculate the optimal water ballast, but some general guidelines are:

- The water ballast should be between 10% and 30% of the total displacement of the boat;

- The water ballast should be placed as low and as far outboard as possible to maximize its righting moment;

- The water ballast should be adjusted according to the wind strength, wave height, and point of sail to achieve the best balance and trim.

The above answers were drafted by sailboat-cruising.com using GPT-4 (OpenAI’s large-scale language-generation model) as a research assistant to develop source material; to the best of our knowledge, we believe them to be accurate.

Recent Articles

Nicholson 35 Sailboat Specs & Key Performance Indicators

Aug 24, 24 02:27 PM

Island Packet 37 Specs

Aug 23, 24 03:17 PM

Jeanneau Sun Odyssey 40 Specs

Aug 23, 24 04:18 AM

Here's where to:

- Find Used Sailboats for Sale...

- Find Used Sailing Gear for Sale...

- List your Sailboat for Sale...

- List your Used Sailing Gear...

Our eBooks...

A few of our Most Popular Pages...

Copyright © 2024 Dick McClary Sailboat-Cruising.com

The Difference Between Tacking And Jibing (Gybing)

7 real reasons why you should own a sailboat, how to set a sailboat anchor in 5 steps, what do you do when there is no wind.

What Is A Water Ballast Sailboat?

On my own sailboat, I have a water ballast system. I was unsure about the stability and efficacy of this system at first. From my experience, a water ballast sailboat, in place of a lead keel boat, is an incredibly worthwhile and effective option to consider when purchasing a sailboat.

What is a water ballast sailboat? A water ballast sailboat has a water reservoir on board instead of a lead keel. Water is taken on board and fills the bottom 25% of the hull. The water in the ballast tanks acts as a counter weight to prevent the wind from blowing the boat over in strong wind.

A water ballast sailboats does have some impressive upsides, but there are some concessions you need to make if you are considering purchasing or chartering this design of sailboat. Below are some important details of both a water ballast system and how they compare to a standard lead weighted keel.

How a Water Ballast System Works

The source for stability on a water ballasted sailboat is the weight of the water in the tanks. The water ballast keeps the boat from rocking back and forth much in the same way a lead keel boat does. If the energy input is sufficient, the boat will roll one way, then the other in both systems. Water ballast stability does not refer to total stability. All sailboats heel over.

Keep in mind these two key principles. The water in the ballast tank takes on the shape of the hull and the floor of the cabin above it. As a general rule, water will always find true level.

When the boat lists or heels over, the water line lifts up and out of the water on one side. The water line on the other side then dips below the surface. As the boat rolls to one side, the water in the ballast tanks is lifted out of the water for a brief moment. Gravity then kicks in and pulls the ballast tank water back to level.

Water Ballast Tanks In Action During Sailing

In keeping with the principles above, when wind pushes on the sails, the boat will tend to lean over. The water in the ballast tanks will be raised up out of the surrounding water as the boat heels over. The further the boat is pushed over by the wind, the more ballast water is being raised above the water the boat is sailing in.

The weight of the water ballast multiplies as the boat is pushed further and further over, until a balance is achieved between the wind force and the gravity pulling level on the ballast tanks. With practice, you can find this balance and maintain it based almost entirely on the amount of sail you have flying at the time.

With the practical application of water ballast systems explained, let’s get into some of the functions of properly and safely working one of these systems.

What Exactly Are Water Ballast Tanks?

Water ballast tanks are large water compartments designed to take in the water that the boat is floating in. They are located under the floor of the cabin of the sailboat. Water ballast tanks typically run most of the length and width of the sailboat. From outside the sailboat, the hull area from the waterline and down is almost completely filled with water. The ballast tanks are manually filled once the boat is placed in the water.

How Are The Ballast Tanks Filled?

There are two key components to a water ballast system on a sailboat. The plug and the vent . The design and innovation on how they are filled and emptied may differ from one brand of boat to another, but the principles are all the same.

The first component is the plug . This is usually located at the lowest point of the sailboat under the water line. This plug opens and closes and allows water to flood and drain the ballast tanks. This plug is opened and closed from inside the cabin of the sailboat using a long rod.

This rod reaches vertically from the plug to the floor of the cabin. It operates the plug, allowing it to be pushed down and away from the hull to open. When the tanks are full, the rod is pulled up, which seals the plug inside or up against the hull, and closes off further water flow.

There is also a vent located beside the plug rod that must be opened while flooding the tanks. This must be open in order for the displaced air to escape as the water in the ballast rises. Once the tanks are full, the plug needs to be closed (rod pulled up) and the vent sealed off in order for the ballast water to keep from entering in the sailboat cabin.

What If the Ballast Tanks Remain Empty?

Empty ballast tanks can be a real hazard on a water ballast sailboat. This may be a point of contention when considering the purchase of this kind of sailboat. Imagine if you will what would happen to an inflated balloon if you glued a roll of dimes on it and set it afloat. Gravity would obviously take hold of the weight and pull the balloon over.

The same principle is at work on a water ballast sailboat, but not necessarily to the same extreme. I have seen capsize reports on the news where too many people were on the deck of an empty water ballast sailboat, and it turned over.

Now, capsizing is not always the case. In situations like the one above, the capsized vessel was overloaded along with having empty ballast tanks. Other factors could also contribute such as being oversailed and in rough water conditions.

In normal sailing situations capsizing would not normally happen. For example, a small family out for an afternoon could board a water ballast sailboat, and forget to fill the ballast tanks.

What they would immediately notice is the sailboat constantly rolling from side to side at the smallest wave, or the slightest movement of people around the boat. Anyone aboard would know something was not right and take stock of the situation and remedy it. Keeping your balance on an empty-ballast-tank boat is no easy task.

Filling and draining ballast tanks is all a part of owning or operating a water ballast sailboat. Hazardous situations arise due to fairly extreme negligence, but they still can happen.

Benefits of a Water Ballast System

Water ballast boats have some unique advantages. If hitting bottom or shallow water sailing is in your future, you would certainly benefit from a water ballast boat.

Fixed keel boats with a lead keel usually have a fairly deep draft in comparison to water ballast boats. Water ballasted boats can get away with a center board, a dagger board or a swing keel since the stability is governed by the water weight and not the keel weight.

This means you have an abundance of anchoring options not available to the majority of sailboats. On top of that, having easy access to shore means I can have a campfire, set up tents and chairs on shore, let the kids run wild until bedtime, and the boat is just a few steps away.

On my own Macgregor 26D, I only need 15 inches of water once the centerboard and rudder are pulled up. This means I can be in very close proximity to shore while at anchor. I have had several tenders from other boats approach me to help while at anchor, because I appear to have run aground. When I explain the water ballast system to them, they smack their head and have a laugh and head on back. It’s really quite amusing.

Drawbacks to a Water Ballast Sailboat

In all honesty, the worst part of a water ballast sailboat is the amount of space the ballast tanks take up overall. In a keel boat, the weight is condensed by the weight of the lead. The floor of the boat can be lower, making for a great deal more headroom than a water ballast sailboat.

Water needs more space for the same weight as lead, and therefore the floor is much “higher” in the cabin of my boat than on a lead keel boat. I can not stand up in the cabin of my boat. I’m 6’2″. There are not a lot of boats under 30ft that I can stand all the way up in, so that’s how I rationalize the discomfort of my boat. First world problems, I know.

Related Questions

Where can/should i dump my water ballast tanks.

There are actually laws that prohibit the dumping of balast tanks in some areas. These laws pertain to vessels that come from remote or foreign parts of the world where ecosystems are very different. Sometimes ballast tanks draw in organisms and planlife that can turn into invasive and unwanted species in a foreign port.

Dumping ballast tanks should always be done at least 10 miles offshore before approaching a foreign port. If you can only dump your ballast tanks once the boat is out of the water, please ensure to do it when you are well inland to prevent the spread of invasive species.

Will the sailboat sink if I forget to close the plug and vent?

This actually happened to me, so I thought I’d share. My 1989 Macgregor 26D did not sink when I forgot to close the ballast plug and vent. I can only attribute it to a safety feature built right into the design of the boat. I don’t really know. All I know is I was distracted by a busy boatlaunch, a motor that didn’t want to start, and a mess of kids bounding around all over the boat. By the time I remembered I nearly had a heart attack. I jumped down the stairs and looked at the ballast vent, and it had stopped filling on its own. I closed everything up and had a great day!

Leave a Comment Cancel reply

If you are a human, do not fill in this field.

This site uses Akismet to reduce spam. Learn how your comment data is processed .

How Does Sailing Ballast Work and Why Do Boats Need It?

What is a sailboat ballast.

Sailboat ballast is a weight carried either in the sailboat keel or hull, typically made of lead, iron, or cement, which acts as a counterweight to the wind's force on the sails' force, providing righting moment by lowering the center of gravity.

Where is the ballast in a sailboat?

Ballast can be carried either in the sailboat keel (keel ballast) or hull (internal ballast). Generally, the majority of the ballast will be located in the keel, since the lower the ballast, the more righting moment it provides.

Where do you put ballast on a boat?

You want to put your ballast in the lowest point of the boat. Typically, ballast is stored in the bilge, where it will have the most effect.

Why do boats need ballast?

Boats use ballast to offset their hull's inherent buoyancy, which creates a tendency to roll. Ballast increases the displacement by lowering the center of gravity, increasing the amount of wetted surface. This improves stability and reduces roll or heel.

How does a boat ballast work?

Boat ballast is a weight that is typically added to the bilge or the keel of a ship in order to increase the weight while simultaneously lowering the center of gravity of the boat. This increases the displacement and the wetted surface, which in turn increases stability and reduces roll.

Sailboat ballast material

Sailboat ballast is usually made from lead or iron , but sometimes cement or water is used as well. Lead is the most expensive ballast material but also has the highest specific weight, reducing the volume.

How much ballast does a boat need?

The amount of ballast needed for a boat depends on several factors, such as displacement, hull design, and boat type. The desired amount is generally expressed as a percentage, also called the ballast displacement ratio . In sailboats, the average ballast ratio is 35-40%, with weights ranging anywhere from 200 to 12,000 pounds .

What did sailing ships use for ballast?

Wooden ships typically used ballast stones, but sometimes extra anchors and cannons were used. Depending on the weight of the cargo weight and crew, ballast stones were added or removed to change the ship's weight accordingly. Ballast was kept in the bilge to lower the center of gravity.

Does sailboat displacement include ballast?

Displacement is always measured including ballast, since adding ballast increases the total displacement.

Leave a comment

You may also like, sailboat keel types: illustrated guide (bilge, fin, full).

The keel type is one of the most important features of your boat. But the different designs can be confusing, so I've set out to create a very clear guide that will …

Sailboat Keels Explained

- New Sailboats

- Sailboats 21-30ft

- Sailboats 31-35ft

- Sailboats 36-40ft

- Sailboats Over 40ft

- Sailboats Under 21feet

- used_sailboats

- Apps and Computer Programs

- Communications

- Fishfinders

- Handheld Electronics

- Plotters MFDS Rradar

- Wind, Speed & Depth Instruments

- Anchoring Mooring

- Running Rigging

- Sails Canvas

- Standing Rigging

- Diesel Engines

- Off Grid Energy

- Cleaning Waxing

- DIY Projects

- Repair, Tools & Materials

- Spare Parts

- Tools & Gadgets

- Cabin Comfort

- Ventilation

- Footwear Apparel

- Foul Weather Gear

- Mailport & PS Advisor

- Inside Practical Sailor Blog

- Activate My Web Access

- Reset Password

- Customer Service

- Free Newsletter

Mason 33 Used Boat Review

Beneteau 311, Catalina 310 and Hunter 326 Used Boat Comparison

Maine Cat 41 Used Boat Review

Cheoy Lee Clipper 36 & 42 Used Boat Review

Tips From A First “Sail” on the ICW

Tillerpilot Tips and Safety Cautions

Best Crimpers and Strippers for Fixing Marine Electrical Connectors

Thinking Through a Solar Power Installation

Stopping Mainsheet Twist

Working with High-Tech Ropes

Getting a Clue for the Blown-Out Clew

Monel Seizing Wire is Worth the Extra Cost

Fuel Lift Pump: Easy DIY Diesel Fuel System Diagnostic and Repair

Ensuring Safe Shorepower

Sinking? Check Your Stuffing Box

The Rain Catcher’s Guide

Boat Maintenance for the Technically Illiterate: Part 1

Whats the Best Way to Restore Clear Plastic Windows?

Mastering Precision Drilling: How to Use Drill Guides

Giving Bugs the Big Goodbye

Galley Gadgets for the Cruising Sailor

Those Extras you Don’t Need But Love to Have

UV Clothing: Is It Worth the Hype?

Preparing Yourself for Solo Sailing

How to Select Crew for a Passage or Delivery

Preparing A Boat to Sail Solo

On Watch: This 60-Year-Old Hinckley Pilot 35 is Also a Working…

On Watch: America’s Cup

On Watch: All Eyes on Europe Sail Racing

Dear Readers

Chafe Protection for Dock Lines

- Sailboat Reviews

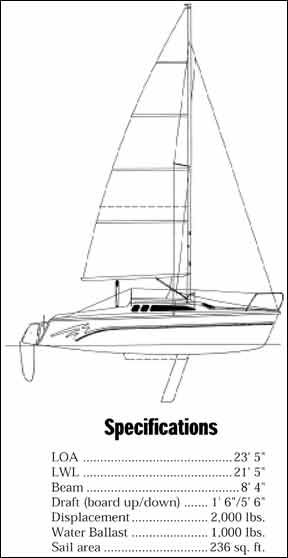

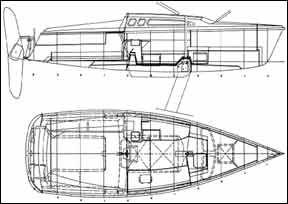

Hunter 23.5

This family cruiser is innovative and has lots of room. in gusty winds, however, it is quick to stall..

Hunter Marine Corp. is noted for its slick, innovative and low-cost mass production sailers. The Hunter 23.5, new in 1992, fits the bill in all respects.

The 23.5 was designed as a trailerable family cruiser for entry-level sailors. Like most Hunters, the boat offers lots of space in the cockpit and down below, and comes with the famous Cruise Pac, which provides just about anything a customer needs, including sails, motor, trailer, lifelines, anchor, life jackets, flares and a copy of Chapman’s Piloting, Seamanship and Small Boat Handling . It’s this type of marketing (plus price: the 1992 price was $13,500) that has helped make Hunter one of the most successful sailboat producers in the U.S.

No one has ever faulted the Alachua, Florida, builder for offering anything but fresh, well-thought out designs. The most striking feature of the 23.5 is its water ballast system, new to Hunter. The system permits an operator to remove 1,000 pounds of ballast from the trailering weight. A retractable centerboard, kick-up rudder and mast that’s fairly easy to step and unstep further enhances trailerability. All told, boat, motor and trailer weigh a combined 2,450 pounds. This model also contains enough foam to provide positive flotation.

While Hunter has enjoyed considerable success with the buying public, it has also suffered from a negative image problem. Earlier PS reviews have criticized Hunter products for a lack of quality control-various systems kinks, lightweight hulls, poor finish work and general absence of blue-water seaworthiness. On the other hand, Hunter owners, while acknowledging a prevailing lack of respect, frequently defend their choice. In the realm of objective data, Coast Guard complaint and recall statistics reveal that Hunter has a better than average record when it comes to hull blistering. (Hunter offers five-year bottom blister warranty protection for the 23.5.) Clearly, the company is doing something right. The model we inspected (hull #8) showed, with very few exceptions, careful attention to detail and finish work in even the least accessible places-more than youd expect on a $13,500 boat. But it is also a boat with some inherent contradictions, in our opinion.

The 23.5 is a highly engineered product with lots of thoughtful features. Hunter, unlike some builders, constructs a mock-up, followed by a prototype that is extensively tested before final design decisions are made. The hull form is modern looking, almost powerboaty in appearance from some angles. Continuing a tendency evident in recent Hunters, the design team has given the 23.5 a relatively full hull, and raised the freeboard to reduce the cabin height, as well as add room below and keep those up top dry in a chop. Because the cabin extends to the rail (no side decks), you must climb over the cabin top to get to the foredeck.

The rig (a B&R design) consists of a 28-foot Z. Spar mast, fractionally rigged with swept-back spreaders that eliminate the need for a backstay (and make un-stepping/stepping, hence trailering, simpler); for the most part, the uppers are aft of the “after” lowers-until deck level-creating a triangular support system. Main and jib halyards are internal and led back to the cockpit. Power comes from a fully battenedmainsail and 110-percent jib (UK Sailmakers-Hong Kong) with a total of 236 square feet. For steering, the traditional wooden tiller has been replaced with a brushed aluminum tube that arches over the walk-through transom (swim ladder comes standard). The aluminum, said chief designer Rob Mazza, weathers better and is easier to arch in order to keep the rudder low and the tiller sufficiently high. Many helmsmen will use the standard Ronstan X-10 tiller extension.

The water ballast/keel system constitutes the key feature of the 23.5. The water ballast-125 gallons, or 1,000 pounds-takes about two minutes to bring on board. The system is activated by flipping up a lid at the base of the companionway, opening a vent and turning a T-valve; the valve in turn drops a circular stainless steel plate aft of the keel, exposing four holes in the hull. (The plate can then be closed flush.) And while you can’t jettison the water downwind, you can swing up the centerboard to reduce draft to 18 inches. The 4-foot centerboard, controlled by the outboard line to the cockpit, moves easily up and down via a cascade block and tackle arrangement.

The apparent thinking of Hunter engineers was to provide a simple, one-step water ballast system that keeps draft shallow while lowering the center of gravity for added stability and righting moment. The ballast-about 16 cubic feet in volume-lies immediately below the waterline. When the water is added, the boat sinks several inches. Nevertheless, while the water adds 1,000 pounds to the overall displacement, its location does not seem to provide sufficient righting moment for windward work in gusty conditions. On racing boats, water ballast is carried above the waterline and outboard under the settees, which of course provides more righting moment. But this water must be pumped into the chambers and drained before tacking-too complicated for Hunter’s purposes.

Construction of the boat is fairly straightforward, with balsa in the hull and plywood in the deck. The plywood core has the potential to encourage water migration should a deck leak occur at some point. The deck/hull joint, with a roll similar to a Hobie 18-a “modified shoebox,” one Hunter engineer described it-is bonded with glass and further fastened by flathead screws through the rubrail. Stanchions, fastened to aluminum backing plates that are glassed in, are sturdy. Though not a heavily-built boat, the 23 looks solid enough; in the absence of a graceful hull form-no sheer here-Hunter provides some added dash with a smoked forward-facing window and a green and purple hull swoosh graphic, which apparently has drawn strong reaction, pro and con (We liked it). Oddly, there is no waterline or boot scribed in the hull. Perhaps Hunter anticipates owners dry-sailing the 23.5, but the absence of a waterline mark will make bottom painting a difficult chore the first time.

Performance

We test sailed the 23.5 off Newport, Rhode Island. In light-air conditions, the shallow-body, lightweight boat (displacement 3,000 pounds with the water ballast) moved up to speed quickly. The boat pointed high and the few light puffs we experienced produced no noticeable helm. We did have some problem finding a definitive groove, especially after tacking. The boat glided through the water easily on a reach and downwind, with the board up, sped along as much as a 23-footer can (Mazza said it will surf under the right conditions). We moved relatively faster, in fact, than a Nonsuch 27 on the same tack.

In stronger 15-20 knot winds, it is a whole different experience. With a single reef in the mainsail, the boat consistently rounds up and stalls. In addition to the boat’s higher vertical center of gravity, this tendency may also be due to the very high-aspect ratio centerboard, which is generally associated with quick stall characteristics.

Complicating matters is the way the rig and sheeting are set up. With no backstay (or topping lift) and no traveler, and with the main sheeted down and far forward near the companionway, the main and sheet are highly stressed. And because the cam cleat for the mainsheet is down near the cockpit sole, it’s difficult to reach-especially in heavy air on a beat, when the helmsman and everyone else is out on the rail. The rounding up and stalling require constant spilling of the main. This may be okay (if tiring) for the experienced sailor, but a bit strenuous and nerve-wracking for the beginner at whom this boat is marketed.

Instead of a single reef, one solution might be to take a second reef in the main in anything approaching 15 knots, but that’s not much of a solution. With 236 square feet of sail-128 in the main, 108 in the foretriangle-for a sail area-displacement ratio of 18.9, the boat should not be overpowered. (The O’Day 23, of about the same displacement, but with 200 more pounds of ballast, carries 246 square feet)

Another solution, although it breaks up the cockpit, might be a barney post where there’s already a slot for the cockpit table, a system that worked well enough in the Alerion-Express. A traveler would be even better, though obviously Hunter wanted to keep the cockpit clear of obstructions as well as avoid the added cost.

Accommodations

You get a lot for your money with this Hunter model. One thing you get a lot of is interior space or, as company literature describes it, “a 25-foot boat in a 23.5 hull.” The main cabin is sizable and has more headroom than we’ve seen on a 23-footer. A pop-top hatch allows those down below to stand up in the center of the cabin. An optional canvas camper top ($300) provides protection from the elements. Poptops are notoriously leaky, and we can’t vouch for this one’s water tightness; however, Hunter has provided drains all around.

The smoked pop-top, plus three ports per side in the main cabin (two small circles, one longer swoosh-style forward) and the forward-facing window provide plenty of light. Hunter has made no attempt to yacht-up the interior: What you get is a basic cream-colored liner, offset on a portion of the topsides by a close-weave grayish fabric someone called “monkey fur.” Despite the plainness, we liked the clean look of the interior.

Aft to port in the main cabin you get a galley station with a one-burner alcohol stove, sink, and fold-out table with storage below. You won’t be whipping up any Cruising World -style feasts in this galley, but it’s nice to be able to heat up some coffee or a cup of soup. Forward of the galley is a small settee/berth, sized right for a child, with storage beneath and a cutout for a portable ice chest. Opposite is a somewhat longer settee/berth of less than six feet, with more storage and a battery compartment below. On the centerline is a slot for a small table that also can be set up in the cockpit.

There are a number of helpful additions: an automatic bilge pump, access plates underneath the cockpit winches. The portable toilet is located to starboard behind a half-bulkhead and privacy curtain, and under the V-berth. Aside from the standard V-berth in the bow, which seems a bit cramped, there’s a double berth (plus stowage) aft of the main cabin, under the cockpit and seats (not for the claustrophobic). It was back here in the bowels of the boat that we spotted the only untrimmed fiberglass.

On deck, there’s an equally roomy cockpit-7′ 9″ long and 6′ 2″ from coaming to coaming. The relatively wide beam makes the addition of a ridge along the centerline for use as a footrest a welcome touch. Foam padding on the seatbacks is another. A lazaret on either side provides on-deck stowage. There’s a #8 Barient winch on either side of the cabin top, each with an attendant cleat. Lines are meant to be kept in the no-name stoppers to starboard. Because of the profusion of lines led back on the starboard side, we’d prefer an extra cleat and winch.

Nonskid is molded in. The foredeck holds an anchor locker, which also contains a padeye for the stepping/unstepping operation. Skipping the details of this procedure-which involves use of a gin pole, the main and jib halyards and a bridle that controls lateral movement-we’d say that Hunter has devised as easy a way to drop a mast as is possible. Once down, the forward end rests in a U-shaped bend in the bow pulpit, the aft end on a roller-topped pole fitted at the transom.

Conclusions

In its attempt to create a simply operated, easily trailered, entry-level boat at a good price, Hunter has come up with some clever compromises. But they are compromises just the same. The 23.5 sails well on all points in light air; it does well off the wind in heavier air. Windward work over 15 knots in this boat is poor in our estimation. We’d strongly recommend that potential customers thoroughly test sail the boat in a variety of wind conditions, experimenting with one or two reefs, to be certain it’s something they’re able-and willing-to handle.

The Hunter 23.5 is clearly striking a chord with some buyers, and assuming many are entry-level sailors, we think it’s great that this boat is attracting newcomers to the sport. The design represents a clever way of managing the trailering problem (i.e., weight and draft). At the same time, we can’t help but wonder if its behavior in gusty winds is worth the convenience of dumping ballast on the launch ramp.

RELATED ARTICLES MORE FROM AUTHOR

excellent article.

Darrell – excellent review. Thanks.

Thanks for the review, I just saw one for sale online.

LEAVE A REPLY Cancel reply

Log in to leave a comment

Latest Videos

The Perfect Family Sailboat! Hunter 27-2 – Boat Review

Pettit EZ-Poxy – How to Paint a Boat

The Boat From True Spirit – Sparkman & Stephens

Top 5 Boat Hacks – Boat Maintenance Tips and Tricks

Latest sailboat review.

- Privacy Policy

- Do Not Sell My Personal Information

- Online Account Activation

- Privacy Manager

- MarketPlace

- Digital Archives

- Order A Copy

The evolution of a water ballast system

Some years ago, I was discussing the performance of my heavy-displacement cruising boat, a Nicholson 32 Mk X, with a good pal of mine. Now Jalingo II had many enviable qualities and sailed well in a blow, but was somewhat reluctant to sail anywhere at all in light airs. Powered as it was by an ancient single-cylinder Saab diesel engine that would set the cutlery dancing gleefully in the galley drawer, this limitation was a little irritating.

Somewhat predictably, the discussion soon converged on the ideal cruising boat for my partner, Mary, and me, which among other things would sail well in light airs but carry its canvas well in a blow. The aforementioned pal, being a yacht designer with expensive habits to support, readily warmed to the developing concept. “Ever thought about water ballast?” he asked. And so the seed was sown.

After much deliberation, we sold Jalingo II and commissioned the designer, Andrew Simpson, to design an 11.5-meter (38-foot) performance voyaging boat that we decided to name Alacazam. Long keels and heavy displacement were out. A new world of righting moments, length/displacement ratios, sail area/displacement ratios and prismatic coefficients emerged; one small step for the designer, a blind leap of faith for us! Alacazam was to be lightish, beamy, fin-keeled — and moderately water-ballasted.

Unlike water-ballasted ocean racers, which are dependent on water ballast for their design righting moment, Alacazam’s system would only provide the additional stiffness associated with having half a dozen crew sitting on the windward rail. The benefit being that water, unlike warm bodies, would not complain in foul weather, need feeding or require a place to sleep. With the ballast tanks empty, it would still have adequate stability under sail, but would need reefing earlier.

Gravity transfer

The seawater ballast is transferred by gravity between two pairs of tanks built into the wood-epoxy hull at the extremity of the waterline beam. This is well below the point of maximum beam but provides the following benefits: As the boat heels, the righting moment increases due to the extended horizontal distance between the center of buoyancy of the hull and the center of gravity of the water ballast.

If caught with the water ballast on the wrong tack, the converse of the above applies such that the heel to leeward is not dramatically affected. Consequently, the leeward tanks can be flooded without the need for pumps, prior to tacking, to get the ballast on the windward side, and subsequently emptied by gravity.

However, the cruising man in me was reluctant to forego the increased freshwater capacity that the ballast tanks could provide. This would mean, however, that to remain within the design displacement, some discipline would be required when we came to take onboard our cruising kit and caboodle. “Everything is a trade-off,” we were reminded. We reasoned that it would be a simple matter to later convert to a seawater system, but not so simple to revert back to fresh water after saltwater contamination.

So Alacazam came to have a freshwater ballast arrangement, using a 40-millimeter-diameter reinforced plastic hose and fittings throughout. Either port or starboard ballast tanks are filled via the deck filler, and the isolating ball valve closed.

The drinking-water tanks (the domestic tanks) are off-the-shelf 135-liter (35-gallon) Vetus polypropylene units, the aft ballast tank has a capacity of 250 liters (65 gallons), the forward ballast tank 210 liters (55 gallons). The ballast tanks are built into the hull sides as part of the structure and, like the remainder of the hull, are sheathed with woven rovings and epoxy resin.

The Vetus tanks are isolated from each other through Y-valves on the inlet side and the supply side, which is intended to prevent any cross contamination. Water from these tanks is delivered through manual pumps to the galley sink, and the washhand basin in the heads. Once empty, they are replenished from the ballast tanks.

Simplicity being one of the key criteria in Alacazam’s design brief, water-ballast transfer was to be by gravity. Although this requires the manual operation of two valves before tacking, it represents no great hardship, as the system is only to be used on long offshore tacks. In a short-tacking situation the water is equalized between the four tanks and closed off. On opening the valves, the water flows from the windward tanks into the leeward tanks, thereby reducing the righting moment and allowing the boat to heel further to leeward and the transfer rate to increase. Provided the heel angle ultimately reaches about 20°, the transfer is completely achieved. If not, sheeting in and bearing away does the trick. Tacking first and remembering about the ballast afterward requires a return to the original tack. This can be embarrassing and is best avoided!

The benefits of ballast

This system was used in Alacazam’s first season, during which it was clear that the water ballast was well worth having, the evident benefits being several. On the wind, Alacazam heels about 6° less for the same sail area and wind strength than it does with the tanks empty, and it sails quicker as a consequence. The concentration of weight in the center section of the boat noticeably improves the fore-and-aft stability and, coupled with less heel, reduces pitch and roll appreciably.

Although this system worked well in practice, improving both performance and comfort, the water transfer was a slow process, and we had no way of knowing when all the water had drained across. Furthermore, the replenishment of the Vetus tanks from the ballast tanks represented something of a problem, as the inlets are at the top of the tanks, and the outlets from the ballast tanks are at the bottom. Water is funny stuff, and gravity is particularly uncooperative in inducing it to go uphill. Consequently, Alacazam had to be heeled to an alarming degree to achieve this transfer, which, of course, the water ballast did its best to resist.

So we now have abandoned the gravity approach and installed a pressurized system deploying two 12-volt Rule centrifugal pumps. One pump is used for the transfer to starboard and the other for transfer to port. Transfer is known to be complete when the pump’s hum changes pitch and the digital current meter registers a drop in current consumption.

Prompted by a firm belief in Murphy’s law, a pump bypass was installed, which enabled transfer by gravity, should the need arise. Whilst the plumbing looks simple on paper, the addition of a third dimension did little to aid the installation of the system, which required a surprising number of plastic junctions and bends to get it all in the available space below the cabin sole.

Less than four minutes

With this system, we can now transfer water between the tanks via the operation of a single Marelon Y-valve and the touch of a rocker switch. The pumps draw about 10 amps, and the transfer takes about 3 1/2 minutes. This is longer than the pumps’ 50-gallon/minute capacity would suggest and is due to the additional internal friction arising from the intestinal nature of the plumbing. The replenishment of the Vetus tanks from the ballast tanks is similarly achieved without the drama of the gravity system.

Mary has developed a distrust of shoreside water supplies and now prefers to drink bottled mineral water. Consequently, we always set out with a good supply of bottles onboard, as well as a reserve 30 liters of water in plastic containers, should we ever need to take to the life raft. (It will be interesting to see if she drinks it then.) Furthermore, most of Alacazam’s visitors tend to avoid drinking anything that hasn’t got alcohol in it, and this, coupled with our usual frugality on passage, means that the contents of just one of the Vetus tanks lasts us a couple of weeks or so. Good-quality drinking water was freely available on our passage south from England through France, Spain and Portugal. So far, the likelihood of using the reserve water in the ballast tanks seems remote.

Clearly, lugging half a ton of water unnecessarily around the ocean does not stack up too well against the original design brief for a performance cruising yacht, particularly when coupled with a blatant disregard for the discipline referred to earlier. It was beginning to look as though we should revert to a seawater ballast system as first intended.

But in January 2002, we had an ocean crossing to make — Canary Islands to the West Indies — so we decided to defer judgement until completion of this passage.

On arrival in Guadeloupe, after an 18-day crossing from Tenerife, we had not drawn on the 460 liters in the ballast tanks, and we still had some 60 liters remaining in the domestic tanks. Taking into account the 25 liters of bottled mineral water that we drank on passage, our average usage was 6.5 liters per person per day. At this rate of consumption, we had another five days’ supply left in the domestic tanks. The 30 liters of fresh water in two plastic jerry cans would give us another four days or so. In total then, we had sufficient water onboard (without that in the ballast tanks) for the two of us for about 27 days, and I’m sure we could stretch this to 30 or so without too much difficulty. We made no attempt to collect rainwater in the frequent heavy squalls that occurred in the latter part of the crossing, but we did use it for impromptu showers.

The trade-wind passage being entirely downwind, water ballast served no purpose and did nothing but slow us down. To neutralize the effect of the water ballast, it was equalized in the port and starboard tanks; consequently, both pairs of tanks were half full. Although the tanks are baffled to prevent surge along their 2.2-meter fore-and-aft length, the free surface area when half full gave rise to a lot of sloshing about, which may well have contributed to the incessant rolling; plus, it was noisy … very noisy. If we could have emptied those tanks, sleeping below would have been easier, and we just might have gotten the 200-mile day I hankered after.

Converting to seawater

The number of passages we plan to make in excess of 18 days are very few indeed, so it would seem that the case for converting to a seawater ballast system is overwhelming. This should be quite straightforward and will require relatively few additional components.

The redundant plumbing is adapted to pump seawater from the galley sink discharge pipe into either pair of ballast tanks. The connection is made immediately above the seacock. This point is always below the waterline, so the pump is primed at all times. A non-return valve will be installed to prevent water draining back out via this seacock before the inline valve is closed. Once the tanks are filled, the inline valve is closed, eliminating the possibility of soggy cornflakes and the like getting into the centrifugal pumps.

The gravity-transfer bypass will be abandoned and the redundant plumbing adapted to provide for discharge over the side during the tank-emptying cycle. Before passing through the hull side just above the port-side waterline, the pipe is looped up to the underside of the deck to prevent seawater from flooding back into the system when the outlet is submerged on the starboard tack. A non-return valve was installed in this line for additional security.

If the ballast-transfer pumps fail and we are left with the water in the leeward tanks, then as a last resort I will disconnect the pipework and allow the water to drain at a controlled rate into the bilge, where the bilge pump will deal with it. Prior to taking this course of action, we will need to be quite sure that the inlet side of the system is properly closed off, or supply could exceed all expectations.

This system will retain the benefit of more stability and power on a reach and when beating to windward, without the weight penalty when off the wind. But what about those passages that could exceed 20 days, or those extended periods at anchor where a freshwater shower after a dip over the side makes life so much more enjoyable?

With the galley sink outlet seacock closed, any (or all) of the ballast tanks can be filled with fresh water via a hose in the galley sink. With some additional plumbing, we can get a further supply of fresh water (or seawater when on passage) at the galley sink, and a freshwater shower in the cockpit.

While this freshwater supply will not be suitable for drinking or cooking, owing to the seawater contamination of the ballast tanks, it will be perfectly adequate for washing up dishes and showering sweaty bodies. Any rainwater collected will simply be poured down the sinks to top off the supply as required, leaving the two Vetus tanks reserved for pure fresh water.

So, by this circuitous development, we have arrived at a system that provides the best of both worlds, all without needing another hole through the hull and not a watermaker in sight.

Dick McClary and his partner Mary live in Plymouth, England, but they spend most of the year cruising aboard Alacazam in the West Indies.

By Ocean Navigator

- News & Views

- Boats & Gear

- Lunacy Report

- Techniques & Tactics

MODERN SAILBOAT DESIGN: Ballast Stability

At the end of our last discussion on stability we mentioned the old mono v. multihull worst-case-scenario debate re sinking to the bottom (monohull) versus capsizing on the surface (multihull). This time we’ll focus on that which drags the poor monohull to the bottom, which is, of course, its ballast. Ballast, ironically, is added to a boat to help it stay upright. As with form stability, the principle is obvious: an object is harder to up-end if a heavy weight is placed at the bottom of it. Witness the iconic inflatable punching clown. With the majority of its weight concentrated at floor level, the clown pops back upright every time you knock it down. This, of course, is exactly what you want your sailboat to do.

Besides helping boats sink, ballast is counterproductive in another way: it makes a boat heavier and increases displacement , thus increasing resistance and decreasing speed. But this sad fact can be mitigated. The amount of ballast needed to counteract the capsizing forces of wind and wave decreases dramatically the lower it is placed in the boat. Unlike the clown, which must always have its feet on the ground, the bottom of a sailboat can reach as far down as there is water for it to float in. This is one reason why racing sailors always prefer very deep keels and why gunkholing cruisers must agonize over the question of draft. On a stock 40-foot boat, for example, the weight differential between a shoal-draft cruising keel and a deep racing keel installed on otherwise identical hulls can amount to 20% or more of the boat’s total displacement. For many, this will seem a heavy price to pay (pun intended) for shoal-draft capability.

Just as weight down low increases stability, weight up high–generally speaking, just about any weight added at or above deck level–decreases it. It is important, therefore, not to think of ballast as a discrete feature. Think instead of a boat’s total weight and how it is distributed. For example, adding one pound of weight at the masthead of a 35- to 40-foot cruising boat effectively subtracts 7 to 10 pounds of ballast from its keel. Conversely, subtracting that pound adds 7 to 10 pounds of ballast. The effects are less dramatic but are still significant when weight is redistributed closer to the boat’s center of gravity.

Aboard most cruising boats, the center of gravity is more or less about 6 inches above the waterline. Any weight subtracted above or added below this point increases the boat’s effective ballast and lowers its center of gravity. Such increases are multiplied according to the weight’s vertical distance from the center of gravity. For example, subtracting 1 pound of weight 35 feet above the center of gravity is equivalent to subtracting 35 pounds 1 foot above it. Adding 1 pound 7 feet below the center gravity is equivalent to adding 7 pounds 1 foot below it.

The bottom line (another intended pun) is that you should always strive to keep weight as low as possible, whether or not it is officially designated “ballast.” This is why racing sailors always embrace technology that dramatically reduces weight aloft, such as carbon-fiber spars and fiber rigging. It is also why cruising sailors should be more circumspect when adding weight to their rigs. Roller-furling headsails, in-mast furling mainsails, extra-heavy wire rigging, mast-mounted radomes, mast steps, and other such gear may improve a boat’s “cruise-ability,” but their cumulative weight also significantly decreases its stability.

Cruisers often store too much gear on deck, which raises a boat’s center of gravity and can make it considerably less stable

Boats that rely primarily on ballast for stability tend to be narrow and deep. In the past they also often had a great deal of deadrise in their hulls, though this is less true now. Narrow, heavily ballasted boats, particularly those with lots of deadrise, usually are tender and quickly heel to significant angles when pressed by even a moderate breeze. But this does not make them “unstable.” When pressed to extremes, they are usually more stable than stiffer boats that rely more on form stability to stay upright. Unlike form stability, which increases a boat’s initial stability, ballast stability increases what is known as ultimate or reserve stability, which is what helps a boat recover and roll upright again–just like the punching clown–after it has been knocked flat or even capsized.

Tender boats, like stiff boats, can be both comfortable and uncomfortable. Their tendency to heel easily often makes inexperienced crew feel nervous and uncomfortable, and even for experienced sailors, working at severe angles for extended periods of time can be taxing. But when the sea gets rough a tender boat normally has a smoother motion than a stiff one. It rolls to greater angles, but does so more slowly, without the vicious snapping and jerking that characterizes the motion of a stiff boat. Sailing to weather in a strong breeze a tender boat’s lee rail will be buried much of the time, and the crew on deck will get wet, but the boat will not pound as violently as a stiff boat.

For cruising sailors, the question of which sort of stability to favor when selecting a boat is a serious one. Many designs available today, of course, are relatively moderate and compromise between extremes. As a general rule, however, popular modern designs tend to be relatively light and wide with shallow bilges, and thus are more stiff than tender. Older designs from the CCA era are usually heavier, narrower, and more tender. As a general rule, coastal cruisers who expect to sail primarily in moderate conditions can, if they like, favor faster, more modern, stiffer designs. Bluewater cruisers who are more likely to encounter extreme conditions should consider whether they’d be better off in slower, more tender design with more ultimate stability.

Shifting Ballast

The most effective way to increase initial stability aboard a boat that may or may not have good form stability is to shift significant amounts of ballast to windward while sailing. This creates a lever arm that operates at a right angle to the sail plan, which increases the ballast’s effectiveness and allows a boat to carry significantly more sail.

Crews on modern planing skiffs like this 49er have to stay well outboard to keep their boats upright

This principle is seen at work on any unballasted sailing dinghy that depends primarily on crew weight to stay upright. To prevent the boat from toppling over to leeward, the crew hikes out on the windward rail. The further to windward they can get, the more sail the boat can carry, as the crew’s effective weight is increased by the longer lever arm. On modern dinghies you often see devices such as trapezes and/or hiking rails that allow crew to get as far outboard as possible. On traditional boats like Bahamian sloops and Chesapeake log canoes the crew sits out over the water on long planks that protrude from the windward rail. When the boat is tacked, the planks are moved from one side to the other, and there is a mad scramble as the crew repositions itself.

A traditional Chesapeake log canoe in action

These days ballast on larger boats can be shifted in more sophisticated ways. In one method known as water ballasting, large quantities of seawater are moved from one side of the boat to the other as it tacks. The water is shifted between dedicated tanks on the outboard edges of the hull’s interior either with a pump or by letting the water run downhill from the windward tank to the leeward tank before tacking. Water ballast augments a conventional ballast keel and is released overboard when it is not needed.

Another way to shift ballast is with a canting keel. These are struts with heavy ballast bulbs that can swing from a vertical position under a boat’s hull out to angles of up to 55 degrees. Large canting-keel monohulls 70 feet and longer have hit top speeds in excess of 30 knots, which is comparable to speeds routinely achieved by large racing catamarans. Several canting-keel boats have sailed 600 miles or more in open water in a single 24-hour period, maintaining average speeds of over 20 knots. What makes canting keels so powerful is that they shift all of a boat’s ballast to windward while keeping it well below the hull, thus greatly increasing its effectiveness. A keel capable of canting 55 degrees requires 25 to more than 60 percent less ballast than a fixed keel to support the same hull and sail plan. The result is a much lighter boat with a much higher SA/D ratio and a much lower D/L ratio.

A modern raceboat with its ballast keel canted to windward. The daggerboards rather than the keel create hydrodynamic lift

Canting keels do have their complications. When canted well to windward a keel ceases to function as a hydrodynamic foil and other foils must therefore take its place. These can be significantly smaller than the keel itself, due to the high speeds at which the boat travels. Often these auxiliary foils are daggerboards in the boat’s midsection, one on each side, with only the leeward board deployed at any given time. Or there may be a second rudder forward of the keel, often called a canard, that works in conjunction with the primary rudder to both resist leeway and steer the boat. This configuration, referred to as the Canting Ballast Twin Foil (CBTF) system , is a patented technology seen on large maxi yachts such as Roy Disney’s last Pyewacket . Centerboards and centerline daggerboards have also been used.

Another major complication is the mechanism that swings the keel back and forth. This mechanism is somewhat simpler on smaller boats, as the top of the keel, which protrudes several feet into the boat’s interior, can be pulled to either side with nothing more than a hefty tackle. On larger boats, however, the weight that must be shifted can be enormous and mechanical assistance is required. This is normally provided by large hydraulic rams and pumps powered by the boat’s main engine or a donkey engine, which must be running when the keel is moving. In all cases the pivoting keel joint in the bottom of the hull must be properly sealed and protected against flooding. Not surprisingly, dramatic failures are fairly routine.

Canting keels have also been installed on a few high-end custom performance cruisers. Examples include the Baltic 78, certain luxury performance cruisers built by Wally Yachts, and a sleek 65-foot one-off boat, Spirit of Adventure , designed by Owen Clarke Design of New Zealand for a private client. The canting keel on Spirit is also a lifting keel, as is the canting keel on the 100-foot super-maxi Maximus , a no-holds-barred racer launched back in 2005. It is unlikely however that canting keels, lifting or otherwise, will trickle down any further into the cruising-boat market. The systems are just too complex, too expensive, and potentially unreliable.

The keel on this custom cruiser, Spirit of Adventure , designed by Owen Clarke Design, both cants side-to-side and shifts up and down (Photo by Paul Todd)

Water-ballast systems, on the other hand, have proven more popular. Indeed, several small trailerable cruising boats use static water ballast as their primary ballast. On these boats the ballast tanks are low in the bilge on the boat’s centerline and are filled after the boat is launched to increase its displacement and stability. When the boat is hauled from the water, the ballast tank is emptied to reduce trailering weight. Since the ballast is never shifted, these are more appropriately termed static variable-ballast systems. Dynamic shifting-ballast systems are less common but have appeared on several performance cruising designs. These include at least one production boat, Hunter Marine’s old HC-50, which was designed to be sailed by a couple. On some other production performance cruisers it is also possible to shift water stored in the freshwater tanks from one side of the boat to the other.

Like canting keels, water-ballast systems make a boat much more complex. The ballast tanks take up interior space that could otherwise be devoted to accommodations, and they require a great deal of extra plumbing for picking up and discharging raw water and for moving it from tank to tank. Because water is not particularly dense, because ballast tanks must be located inside rather than below the main hull, and because the water ballast represents only a portion of the boat’s total ballast, water-ballast systems also do not have nearly as dramatic an effect upon performance as do canting keels.

Related Posts

COMPREHENDING ORCAS: Why the Heck Are They Messing With Sailboats?

DEAD GUY: Ted Brewer

These are useful advice. Thanks! For quality and affordable boat ballast check out http://www.waterskiersworld.com/category-list/accessories/boat-ballast-fat-sacs-pumps.html

Found this looking for research on a short high-school presentation on how boats work. Made my head hurt with funky words. 10/10

Very helpful in analyzing where to put 500 pounds of batteries for a conversion from diesel to electronic propulsion.

Leave a Reply Cancel Reply

Save my name, email, and website in this browser for the next time I comment.

Please enable the javascript to submit this form

Recent Posts

- MAINTENANCE & SUCH: July 4 Maine Coast Mini-Cruz

- SAILGP 2024 NEW YORK: Lifestyles of the Rich and Famous

- MAPTATTOO NAV TABLET: Heavy-Duty All-Weather Cockpit Plotter

- DEAD GUY: Bill Butler

- NORTHBOUND LUNACY 2024: The Return of Capt. Cripple—Solo from the Virgins All the Way Home

Recent Comments

- Brian on THE BOY WHO FELL TO SHORE: Thomas Tangvald and Melody (More Extra Pix!)

- cpt jon on NORTHBOUND LUNACY 2023: Phase Two, in Which I Exit North Carolina via Oregon Inlet

- Sanouch on A PRINCE IN HIS REALM: The Amazing Life of Thomas Thor Tangvald

- Peter Willis on DEAD GUY: Donald M. Street, Jr.

- January 2024

- December 2023

- November 2023

- October 2023

- September 2023

- August 2023

- February 2023

- January 2023

- December 2022

- November 2022

- September 2022

- August 2022

- February 2022

- January 2022

- December 2021

- November 2021

- October 2021

- September 2021

- February 2021

- January 2021

- December 2020

- November 2020

- October 2020

- September 2020

- August 2020

- February 2020

- January 2020

- December 2019

- November 2019

- October 2019

- September 2019

- August 2019

- January 2019

- December 2018

- November 2018

- October 2018

- September 2018

- August 2018

- February 2018

- January 2018

- December 2017

- November 2017

- October 2017

- September 2017

- August 2017

- February 2017

- January 2017

- December 2016

- November 2016

- October 2016

- September 2016

- August 2016

- February 2016

- January 2016

- December 2015

- November 2015

- October 2015

- September 2015

- August 2015

- February 2015

- January 2015

- December 2014

- November 2014

- October 2014

- September 2014

- August 2014

- February 2014

- January 2014

- December 2013

- November 2013

- October 2013

- September 2013

- August 2013

- February 2013

- January 2013

- December 2012

- November 2012

- October 2012

- September 2012

- August 2012

- February 2012

- January 2012

- December 2011

- November 2011

- October 2011

- September 2011

- August 2011

- February 2011

- January 2011

- December 2010

- November 2010

- October 2010

- September 2010

- August 2010

- February 2010

- January 2010

- December 2009

- October 2009

- Boats & Gear

- News & Views

- Techniques & Tactics

- The Lunacy Report

- Uncategorized

- Unsorted comments

${ error } X

Your cart is empty

- Buyers Guide

- How-To-Guide

- Product Review

- Project Boat

Lead Ballast vs. Water Ballast: What's the Difference?

Types of Boat Ballast

For boat owners, weight and balance are important factors for a fun day on the lake. Or as we like to say, only a few letters separate "ballast" and "blast!" With multiple ballast products available, different locations for weighting your boat based on your sport, it can be a lot to search through when you’re trying to choose the best ballast weight solution for your craft. Buying weighting and balancing materials for your boat is an investment, which is why we want to provide you with all the information needed to help make the right decision. In this post, we'll discuss what makes lead ballast and water ballast unique, as well as their respective benefits so that you can make a well-informed purchase that meets your needs.

What is Lead Ballast?

While solid ballast weight is commonly referred to as lead ballast or lead weight, ballast brands don't actually use true lead in their solutions. Instead they use steel shot remnant, steel scrap, or small steel pellets.

So while steel is much more dense than water, it's not as dense as actual lead. In fact, if one were to use lead, it would occupy nearly half as much space by volume compared to steel shot. That's why we prefer to make the distinction of “solid ballast", meaning not water-based, not liquid, but a solid as that covers any type of solid ballast application, whether that's steel shot, concrete, sand or rocks.

Lead Ballast vs. Water Ballast

The primary consideration when it comes to utilizing solid ballast as opposed to water ballast is that no matter what happens, you've got that solid ballast with you and you're not getting rid of it. Whether it's a day on the water, trailering your boat to and from the lake or lifting the boat up on your boat lift, water ballast gives you the ability to quickly and easily drain the ballast and just like that, it's gone. You don't have to suffer the consequences of carrying the ballast around with you everywhere. So you have it when you need it and you don't have it when you don't need it. This makes water-based ballast the overwhelmingly favorite option in the majority of scenarios when you need a lot of weight and you have the space for it.

That's not to say there aren't scenarios or applications where solid ballast makes sense. For example, if you need a significant amount of weight in a relatively small volume of space like up in the bow of the boat to move the center of gravity forward solid ballast can be a great choice. Or maybe you need some extra weight on the port side of the boat to offset prop rotation or the weight of the driver, who is always going to be on the starboard side of the boat. The density of solid ballast means you can get the amount of weight you need without occupying a significant amount of space within the boat, which makes solid ballast a great option to consider.

Issues with Lead Ballast

Special caveats around using solid ballast exist as previously mentioned when it comes to trailering and putting your boat on the lift. For example, if you were to add 300 pounds of weight to the bow of your boat to move the center of gravity forward, it's very easy to exceed the rated capacity of your tow vehicle's hitch because effectively all of that weight is picked up by the tongue of the trailer and none of it is transferred to the axles of the trailer. That means best case you're transferring weight back and forth from the bow of the boat to the middle of the boat every time you trailer. And worst case, you'll have a significant safety issue on your hands if the tow vehicle is overloaded.

Similarly, solid ballast can pose a problem when dealing with your boat lift. So even if you don't trailer your boat, it's still something to be aware of. Many older lifts weren't built for today's modern wake and surf boats as the weight of the boat itself has doubled in the last decade. That means you might be up against the limit of your boat lift without any additional ballast onboard. Add another 500-1,000 pounds of solid ballast that's always there and you're going to have significant issues with your lift's capacity. We've seen many lifts fail as a result of this and it's not a pretty sight.

When does solid ballast make sense?

Steel shot based ballast can be a great tool when used appropriately. Our soft recommended limit is typically 300 to maybe 500 pounds at the high end. Anything over that, you probably should be looking at water based ballast to pick up the majority of the weight that you need and then rely on the solid ballast as a supplement. It's great to have a few 25lb and 50lb bags on-hand to help dial in your wake as needed.

Hopefully that explains some of the pros and cons of solid or lead ballast versus water based ballast. If you have any additional questions, feel free to reach out by phone at (888) 338-6085 , by email to the [email protected] , or leave a comment below and a product advisor will be happy to talk you through it.

Related Posts

What to Do If You Have a Sumo Ballast Bag and Need a Pump to Fill It

10 Must-Have Boat Accessories

Top Wakefoils of 2024

Post comments, submit comment.

Please note, comments need to be approved before they are published.

- Choosing a selection results in a full page refresh.

All About Water Ballast Systems Advantages of Existing Internal Water Ballast Systems How Water Ballast Increases Boat Speed and Comfort Advantages of New External Water Ballast System Stability and What Hangs In The Balance

Advantages of Existing Internal Water Ballast Systems

M any new high performance racing and cruising sailboats are being manufactured with built-in rigid internal water ballast tanks to improve their upwind performance, without sacrificing downwind performance. This is accomplished by filling the windward ballast tank with water while going upwind to stabilize the sailboat, and emptying the ballast when going downwind for less weight. Reducing the angle of heel not only increases performance but also increases comfort and safety similar to sailing down wind. The cockpit is much more comfortable and you have a safer working platform, especially on the fore deck. Below deck tasks such as cooking, using the head or sleeping (in improper sea berths) are made safer and easier in heavy seas. Even when just day sailing with friends and family it becomes more comfortable -- everyone likes a nearly level boat! Reefing is also minimized by stabilizing the boat in moderate conditions and not having to depower the sails.

Examples of internal water ballast manufactured into high performance cruising sailboats can be found in Roger Martin's 40 foot Gray Wolf, with the following advantages:

" with winds westerly at 15 to 18 knots. Our initial angle of heel, close reaching with full main and 120 percent jib, was near 10 degrees. This all but disappeared after Rodger scurried below and switched on a Rule 3600 pump to fill the windward ballast tank. Our speed subsequently increased by a knot, to say nothing of our comfort level." "Each port and starboard tank holds 262 gallons (2,240 pounds). " CRUISING WORLD magazine June 1997, page 91.

and also, in Steve Dashew's 80 foot Beowulf: