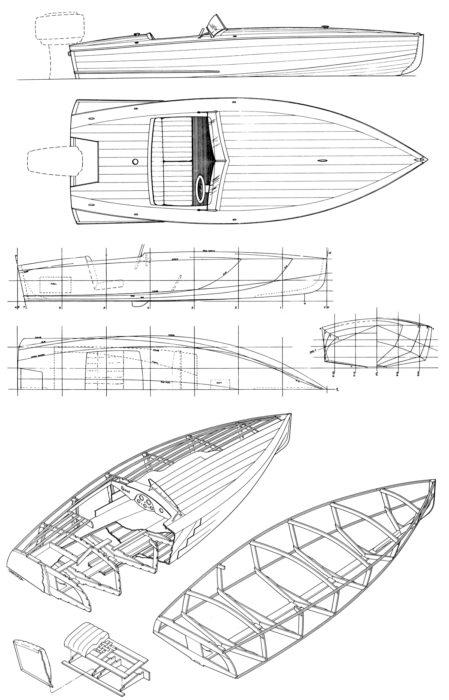

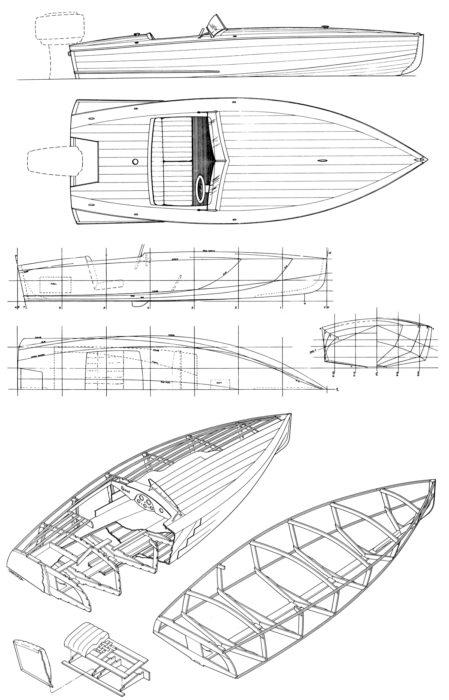

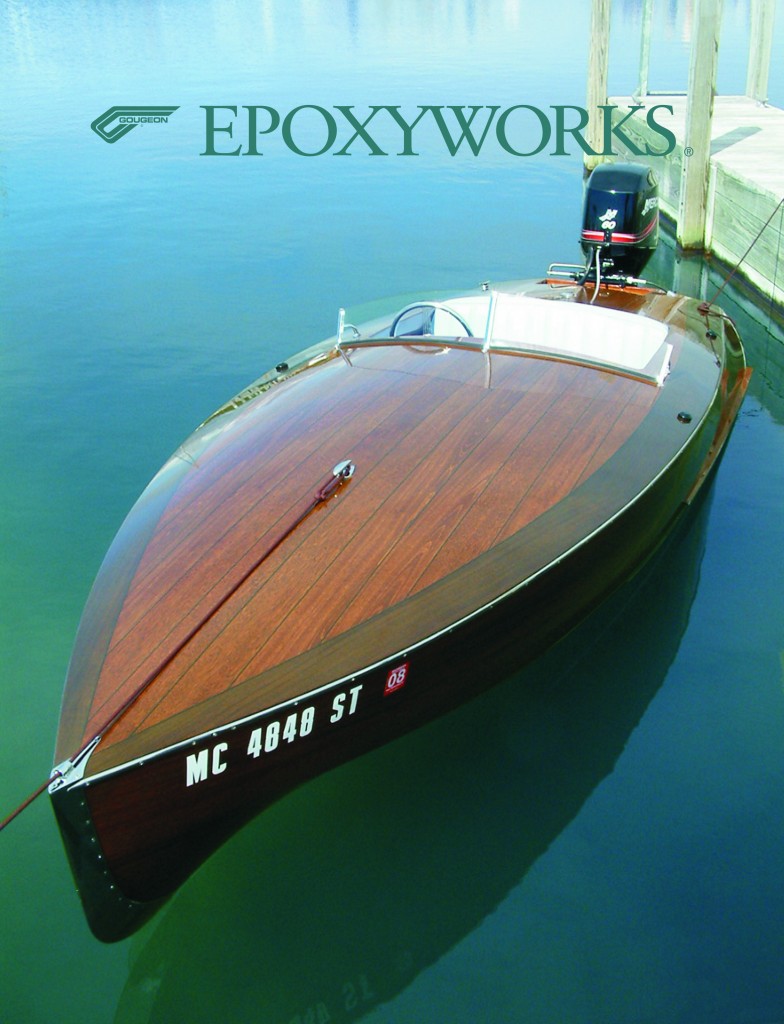

| Posting Rules | | post new threads post replies post attachments edit your posts is are code is are are are | | Similar Threads | | Thread | Thread Starter | Forum | Replies | Last Post | | | inishowen | Monohull Sailboats | 29 | 25-07-2014 11:38 | | | Dollydagger | Monohull Sailboats | 27 | 17-10-2011 11:54 | | For Sale: | mcfirth | Classifieds Archive | 3 | 07-03-2010 17:38 | | | jimhotdog | Crew Archives | 9 | 27-09-2009 11:24 | | | ssullivan | Sailor Logs & Cruising Plans | 8 | 08-05-2006 16:15 | Privacy Guaranteed - your email is never shared with anyone, opt out any time. Boat Profile A playful runabout From Issue Small Boats Annual 2007 R ASCAL sped across the riffled waters of Long Island Sound. Her mahogany foredeck glowed from the depths of its varnish, and her stainless-steel cutwater sparkled through drops of water streamlining into mist. Driver and passenger sat low on a simple rolled leather seat, legs stretched out nearly parallel to the cockpit sole. A tall person could reach over the side and touch the water as it rushed aft at better than 50 mph. Memories of my first ride in RASCAL still raise goose bumps after 15 years. At 15′ in length and weighing about 1,000 lbs with a full fuel tank and cockpit, RASCAL is a cheeky little boat— “pleasantly mischievous” is one of the ways Merriam-Webster’s Unabridged Dictionary defines the name—powered by a 60-hp Mercury outboard. If Colin Chapman had designed and built boats instead of Lotus automobiles, a boat of RASCAL’s character surely would have been among them—the Lotus Super Seven of the waterways.  Rascal, a 14’10” outboard runabout that you can build in the backyard, strives to capture the cachet of big mahogany speedboats—without their mechanical complications and great expense. Designed and built by Kenny Bassett, Onion River Boat Works, RASCAL offers more bang for the buck than just about any other runabout a father and son could build over several hundred hours of nights and weekends. They will build her of plywood—4mm for the topsides and decks, 5mm for the bottom—ripped into strips 1″ wide and laid diagonally over frames and stringers. That’s the easy part. If they want to capture the gloss and romance of traditional mahogany runabouts, they’ll plank the topsides with 1⁄ 4″ solid mahogany, perfectly lined off and set in epoxy. Although this method taxes the skill and patience of an amateur builder, it’s far from impossible. In fact, Tom Donahue, an electrical engineer living in Connecticut, recently completed a Rascal. Before this project, he’d built nothing more demanding than a couple of birdhouses. Donahue knows, maybe better than anyone, that whoever builds a Rascal must let patience guide them throughout the project, especially during the varnishing. The finishwork will likely require as much, or more, time than the construction. The final result, though, is worth the wait. RASCAL rides atop a shallow-V bottom. Her steep entry warps into a flat run and ends at the transom in a deadrise of about 7 degrees. A delta-shape pad keel from station No. 2 aft to the transom provides a perfect planing surface, allowing RASCAL to make the transition from displacement speed to full plane in a single heave—absent the “hump” we associate with deep-V hulls and their slightly shallower modified-V sisters. Chine flats emerge from the waterline at station No. 4, which corresponds with the forward edge of the cockpit. They rise gracefully and embrace the stem about halfway up the bow, forming a line that plays with light and shadow to create visual interest forward of the cockpit. These chines also deflect spray. RASCAL’s exceptional proportions mask her size when she stands alone in the slip or speeds across the water. Only when she’s parked next to a larger boat does she reveal her compact dimensions. The outboard’s power head, like a welt on the forehead of Julianne Moore, may diminish our first impressions from exquisite to merely beautiful, but familiarity ought to heal the wound. Bassett was aware of this possibility, so he painted the cowling of the outboard on hull No.1. A lustrous solid black accented by the name RASCAL in chromed script made the power head an integral part of the design, further defining the boat’s character and purpose. I’d met Bassett at the Riverside Yacht Club in the town of the same name located two train stops east of Greenwich, Connecticut. He’d traveled from New Hampshire to demonstrate the boat to a prospective buyer and invited me to join him for a test drive afterward. Bassett fired up the three-cylinder Mercury, which was still warm from his demo, engaged forward gear, and idled us into the channel.  Powered by a 60-hp, Mercury outboard motor, RASCAL scoots along at better than 50 mph. At rest and under slow way, RASCAL lightly tap-danced to the rhythm of cat’s-paws stirred by the breeze. This lateral motion is common to other runabouts I’ve driven and seems to be a characteristic of the bottom’s shape and the boat’s low center of gravity. I love this little dance, because it conveys a restless energy—the promise of speed. Most runabouts fulfill this promise, whether they are blindingly fast or simply pleasingly rapid. Few powerboats involve us in their playfulness as completely as does a fine runabout, and RASCAL’s length and light weight intensify all of the sensations—save one: the rumble of an inboard engine, V-8, or straight-six barking epithets from the chrome tips of a through-transom exhaust. When I drove the original RASCAL, a 60-hp Mercury two-stroke outboard powered her, and I admit to being disenchanted by the ring, ding, ding voice coming from the transom. Sure, I knew better. I had road-raced two-stroke motorcycles in the late 1960s and early 1970s, and understood their potential to entertain the speed demon in all of us. I knew also that this lightweight outboard was the key to RASCAL’s personality. Never mind Gar Wood’s neat 16′ Speedster inboard runabout or, to be more contemporary, Donzi’s lovely Sweet 16 sterndrive, only an outboard would give Bassett everything he wanted—simplicity of installation, ease of maintenance, purchase price, light weight and performance. Although outboard-powered classics never gained the cachet of their inboard sisters, they’ve written a richly colorful history for themselves in racing and more sedate forms of boating. In RASCAL, Bassett has combined the spirit of the all-conquering Switzer Craft hydroplanes and utilities with the look and presence of a Gold Cup raceboat. After we cleared the mooring field and the no-wake zone, Bassett trimmed the outboard’s drive leg and pushed the throttle to the stops, sending us in a single rush to a speed of 50 mph. In the open water, RASCAL skimmed atop a foot or so of chop, doing her best imitation of a Lotus Super Seven tearing along a country lane in the north of England. Hard left, hard right, the little boat put her shoulder into the turns and carved perfect arcs. A tiny skid fin, at the leading edge of the planing surface and projecting to a depth of 2 3⁄4″ from the pad keel, helped RASCAL hold her line and speed in these turns. Without the fin, she would drift wide—her way of asking the driver to back off the throttle. We played until our faces ached with indelible grins and the electric tilt and trim on the outboard quit working.  Designer-builder Ken Bassett drives RASCAL at speed. The playful runabout isn’t the easiest boat to build, but she rewards careful work with fine performance and head-turning appearance. We met again later in the summer—this time on Candlewood Lake, near Danbury, Connecticut. This lake is an impoundment and is very narrow in many sections. Wind-blown waves and the wakes of powerboats bounce off the shorelines and march directly back toward the center of the lake. Picture the inside of a washing machine, the agitator of which moves rapidly up and down. Even during the week, motorboat traffic on Candlewood resembles the madness of I-95 between New Haven and Greenwich, so we looked for relatively quiet water to time her acceleration and top speed in fresh water. We recorded 2.7 seconds from 25 to 35 mph and a maximum speed of 52 mph. My turn to drive. The cockpit is intimate, the steering wheel small, and the gauges are located in a panel at the center of the dashboard, similar to the arrangement in a 1952 Jaguar XK120. The seat is a paragon of simple design and construction, a pair of leather-covered foam cushions resting on nylon webbing. As drawn, the cockpit ought to accommodate a reasonable variety of human heights and widths. If I were going to build a Rascal, I’d figure out a way to make the seat adjustable fore-and-aft. The unassisted cable-operated steering was quick, and RASCAL’s response nearly instantaneous. At first, the boat’s quickness startled me, so I eased back on the throttle until I got the feel of her handling. In those washing machine waters, she preferred staying on top of the conditions, so the faster we went, the smoother was her ride. RASCAL reacted predictably to changes in the outboard’s trim. Trimming in brought the bow down to engage the waves; trimming out raised the bow, transferring the load to her planing surface under the cockpit. She never porpoised, chine-walked, or tried to get airborne. One owner of a Rascal has clamped a heavily modified outboard onto the transom and regularly sees 70 mph. He has reported that she remains free of handling vices. Like a pleasingly mischievous friend, RASCAL defies anyone to resist her charm, her playfulness, and friendly manners. She may not be the easiest boat to build, but rendering the two-dimensional drawings into all her wonderful three-dimensional shapes may make you as giddy as does driving her.  Ken Bassett retired and closed Onion River Boatworks in 2017; there are no plans available for RASCAL. The review is presented here as archival material. Is there a boat you’d like to know more about? Have you built one that you think other Small Boats Magazine readers would enjoy? Please email us! Share this article Join The ConversationWe welcome your comments about this article. If you’d like to include a photo or a video with your comment, please email the file or link. Comments (9)I built Rascal in 1998. It was challenging but very rewarding and I also installed a 60HP Mercury. As I wanted to move on to other projects, I sold the boat. Some years later I completed a 26′ triple-cockpit runabout that I brought to a wooden boat show in Lake Hopatcong, N.J. where the same Rascal was on display! Great article, inspiring. Thanks JP I am currently building a Ken Bassett Rascal. I have talked to Ken several times for advice as well as the WoodenBoat community. Everyone was very helpful. I am a first-time boat builder with several years of WoodenBoat school classes to support my endeavor. I am enjoying the challenge. If you are building a Rascal boat or thinking about building, please reach out to discuss. What do you estimate the cost of materials to be for this design? Could the boat be designed for two smaller outboards? What a gorgeous little boat! I’m intending to build one as soon as I’ve finished fixing up a put-put I’ve restored, but the engine is a disaster. The Minister of Home Affairs has dictated this must be completed first! It’s called One Day which may give a clue to the directive. I’m in Australia, so talking with Ken may be an issue, is there an email address through which I could contact him? A very dear friend purchased a Rascal that has the natural wood with a light-blue side accent color. What a pleasant surprise when he brought it to the lake. The gentleman who built it produced a fine piece of furniture. The workmanship is second to none. The wood absolutely glistens and the painted accent stands out. When he drives his Rascal along the shoreline, it has all of the embodiment of a classic runabout. The ride can only be stated as: EXHILARATING! You cannot appear graceful when boarding, but the payoff is a lot of fun on the water. My dad built a 15′ Rascal in 1985 which we now must have valued for his estate. Would anyone be able to give me some idea as to the market value? It’s in excellent shape. Where can I get plans for the Rascal? The Rascal article was originally published in 2012 and we added this note to the end of it for this second appearance: Ken Bassett retired and closed Onion River Boatworks in 2017; there are no plans available for RASCAL. The review is presented here as archival material. Leave a Reply Cancel replyYour email address will not be published. Required fields are marked * Stay On Course More From This Issue The NorseBoatThe NorseBoat requires more study time per foot than most small craft. Besides an attractive hull and an unusual sail plan, she has more bells, whistles, and unexpected features than…  Already a monumental success in 1950, Chris-Craft thought to use up their mountain of mahogany scrap by cutting kits for handsome plywood power skiffs. It must have been some mountain;…  The Ness YawlFew boats developed from a traditional working boat are as adaptable to small boat sailing as a Ness Yawl, and few are as much fun. It’s worth remembering, however, that…  Paul Gartside's plans for modest-sized cruising boats inspired by the Falmouth cutters of his native England should all come with one of those warnings from the Surgeon General, this one…  The Tolman SkiffRenn Tolman designed his eponymous skiff as a workhorse for rugged Alaskan environs. The boat has proven to be adaptable to a wide range of locales—and to a wide range…  RASCAL sped across the riffled waters of Long Island Sound. Her mahogany foredeck glowed from the depths of its varnish, and her stainless-steel cutwater sparkled through drops of water streamlining…  With his Stir Ven design, a 22' LOA center- boarder, François Vivier took first place in the “neo-traditional” category of a 1997 design competition organized by the French magazine Le…  The West Pointer 18Six River Marine based this tough and shapely skiff on a highly regarded workboat designed and built by Alton Wallace. Chip Miller gave the new boat more freeboard, less flare,…  Skylark was designed by Paul Gartside for day-sailing in the sporty estuary and ocean waters off the Oregon coast. With a 14' length and a 5'8" beam and tipping the…  Conceived in the early 1980s by Ken Bassett, Onion River Boat Works, and massaged into her final form by Phil Bolger, BLACKBIRD embodies the spirit of carefree mobility found in…  PETITELISA is a synthesis of Gilles Montaubin’s long experience with sail-and-oar boats. Unlike many boats of this type, she is not reminiscent of any traditional working boat type. Instead, she…  People are always drawn to the warmth and the visual texture of a varnished wood kayak, but the beauty of a plywood kayak can and should be more than skin…  The FlatfishEvery sailor has his own vision of the perfect daysailer. For many, this ideal boat is based on the Herreshoff 12 1⁄2, Nathanael G. Herreshoff’s iconic daysailer, which debuted in…  The Boothbay Harbor One-DesignThe Boothbay Harbor One-Design, a short-ended Burgess, moved to mid-coast Maine and hired Geerd daysailer with a long waterline, is a particularly handsome boat that has proven itself in the…  The Christmas WherryThe Christmas Wherry possesses two characteristics that should be critically important to anyone looking for a small boat to use in open waters. It displays classic beauty and, as the…  The Gloucester Light DoryIn the early 1980s, I bought Phil Bolger’s plans for the 15′ 6″ LOA Gloucester Light Dory. I was living in an apartment at the time, and I was intending…  Endeavour 17The Steve Killing–designed Endeavour 17, a kayak built of cedar strip planks and fiberglass, combines beauty, fast lines, load-carrying capacity, and relatively easy construction. Let’s have a look at each…  The Lake Oswego BoatFew joys in life are simpler than a morning row. Oars over the shoulder, hollow footsteps along a wood-decked float, the boat quivering with the first step aboard, the sharp…  Harry Bryan, a boatbuilder and designer from New Brunswick, Canada, designed the Fiddlehead, a 10 1⁄2' double-paddle canoe, in 1992 after his sister-in-law introduced him to her Wee Lassie. The…  The Macomber 15You can walk across the Westport River in southern Massachusetts at low tide. It's a mile or so across in some places, but the depth at full ebb is only…   The Sailing Skiff 15All youngsters might begin their waterborne adventures in flat-bottomed rowing/sailing skiffs. Easy to build, but difficult to design properly, these honest little boats teach lessons in seamanship and self-reliance. At…  The WindSprite 26Frank Pedersen designed a light-displacement planing hull, and WINDSPRITE's abilities as a performance daysailer have been anything but a disappointment to him. With basic accommodations and without expensive electrical or…  The Annapolis WherryFaster than a typical skiff, yet more stable than a recreational shell, the light (65 lbs) Annapolis Wherry from Chesapeake Light Craft offers healthy exercise and satisfying speed. The Wherry…  The Ben GarveysBoats don’t always need to have pointy forward ends. Here we have two easily built, square-ended workhorses that will handle all sorts of waterfront chores—and look just fine while they’re…  The Norwalk Islands 26The sheet-plywood Norwalk Islands Sharpie can easily be built in the backyard, yet it outperforms more expensive yachts. Its simple cat-ketch rig needs no standing rigging (wire shrouds and stays… More Boat Profile The West BranchFrom the 2008 Small Boats Annual - Unlike its square-sterned cousins, the West Branch canoe can carry a small motor on its transom while retaining the good paddling qualities of…  Before Sam Devlin fired up the motor and backed BANJO from the dock, the two of us relaxed in the cabin and chatted about boats each of us had designed…  The Sea Bird YawlIn 1988, boatbuilder Alex Hadden of Georgetown, Maine, launched his Sea Bird yawl, using a marconi rig recycled from an earlier boat that had been cut up. More than 20… Subscribe Today!Become a subscriber today and you’ll recieve a new issue every month plus unlimited access to our full archive of backlogged issues. Already a subscriber? Sign In Subscribe For Full AccessFlipbooks are available to paid subscribers only. Subscribe now or log in for access.  Rascal 14 BrochureOriginal manufacturer / promotional brochure. Date: 1960s Pages: 4 in B&W Size: 8.5 x 11 opens to 11 x 17 Condition: C8 Share this item: Related Products Rebel 16 Brochure Ray Greene 1960s Brochure New Horizons Brochure | Go to

Rebel Rascal 14, 1980 Great condition Has Quantum sails main and jib, excellent condition. at [email protected]

| |  Great choice! Your favorites are temporarily saved for this session. Sign in to save them permanently, access them on any device, and receive relevant alerts.  1981 14' Spindrift RascalSeller's DescriptionVery easy to sail and super light Rascal Sailboat. Both jib and main sails are in very good condition. Super easy and fast to set up on the beach. You can tow it with a regular sedan (super light construction). Rig and SailsAuxilary power, accomodations, calculations. The theoretical maximum speed that a displacement hull can move efficiently through the water is determined by it's waterline length and displacement. It may be unable to reach this speed if the boat is underpowered or heavily loaded, though it may exceed this speed given enough power. Read more. Classic hull speed formula: Hull Speed = 1.34 x √LWL Max Speed/Length ratio = 8.26 ÷ Displacement/Length ratio .311 Hull Speed = Max Speed/Length ratio x √LWL Sail Area / Displacement RatioA measure of the power of the sails relative to the weight of the boat. The higher the number, the higher the performance, but the harder the boat will be to handle. This ratio is a "non-dimensional" value that facilitates comparisons between boats of different types and sizes. Read more. SA/D = SA ÷ (D ÷ 64) 2/3 - SA : Sail area in square feet, derived by adding the mainsail area to 100% of the foretriangle area (the lateral area above the deck between the mast and the forestay).

- D : Displacement in pounds.

Ballast / Displacement RatioA measure of the stability of a boat's hull that suggests how well a monohull will stand up to its sails. The ballast displacement ratio indicates how much of the weight of a boat is placed for maximum stability against capsizing and is an indicator of stiffness and resistance to capsize. Ballast / Displacement * 100 Displacement / Length RatioA measure of the weight of the boat relative to it's length at the waterline. The higher a boat’s D/L ratio, the more easily it will carry a load and the more comfortable its motion will be. The lower a boat's ratio is, the less power it takes to drive the boat to its nominal hull speed or beyond. Read more. D/L = (D ÷ 2240) ÷ (0.01 x LWL)³ - D: Displacement of the boat in pounds.

- LWL: Waterline length in feet

Comfort RatioThis ratio assess how quickly and abruptly a boat’s hull reacts to waves in a significant seaway, these being the elements of a boat’s motion most likely to cause seasickness. Read more. Comfort ratio = D ÷ (.65 x (.7 LWL + .3 LOA) x Beam 1.33 ) - D: Displacement of the boat in pounds

- LOA: Length overall in feet

- Beam: Width of boat at the widest point in feet

Capsize Screening FormulaThis formula attempts to indicate whether a given boat might be too wide and light to readily right itself after being overturned in extreme conditions. Read more. CSV = Beam ÷ ³√(D / 64) Spin.: 160 sq. ft. A later, slightly modified version was available called the RASCAL II. This listing is presented by SailboatListings.com . Visit their website for more information or to contact the seller. View on SailboatListings.com Embed this page on your own website by copying and pasting this code. ©2024 Sea Time Tech, LLC This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply. - Скидки дня

- Справка и помощь

- Адрес доставки Идет загрузка... Ошибка: повторите попытку ОК

- Продажи

- Список отслеживания Развернуть список отслеживаемых товаров Идет загрузка... Войдите в систему , чтобы просмотреть свои сведения о пользователе

- Краткий обзор

- Недавно просмотренные

- Ставки/предложения

- Список отслеживания

- История покупок

- Купить опять

- Объявления о товарах

- Сохраненные запросы поиска

- Сохраненные продавцы

- Сообщения

- Развернуть корзину Идет загрузка... Произошла ошибка. Чтобы узнать подробнее, посмотрите корзину.

Oops! Looks like we're having trouble connecting to our server.Refresh your browser window to try again. Related Searches- sail boat with trailer

- sailboats used

- sail boats for sale

- sailboat sail

- 42 foot sailboat

- sailboat trailers used

- sailboats for sale by owner

- sail boats for sale florida

- used sails for sale

- trailer for sailboat

- sailboat vintage

- motor sailboat

- sea ray boats for sale

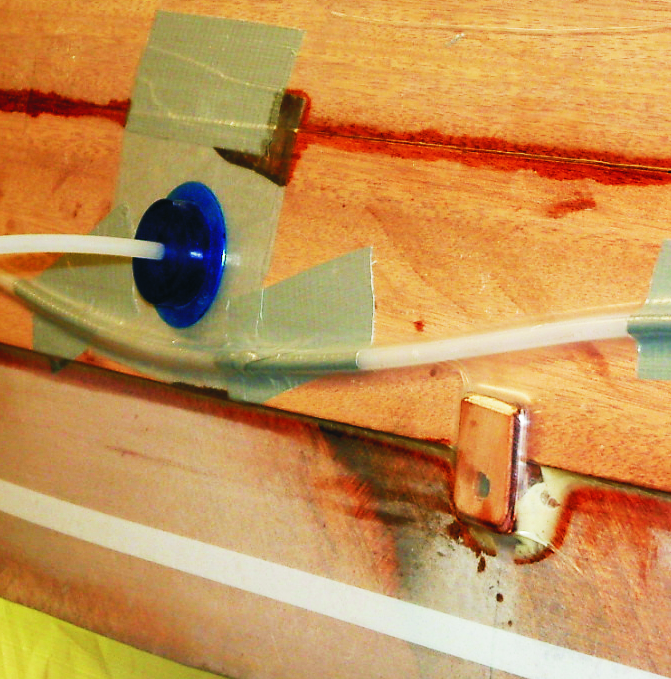

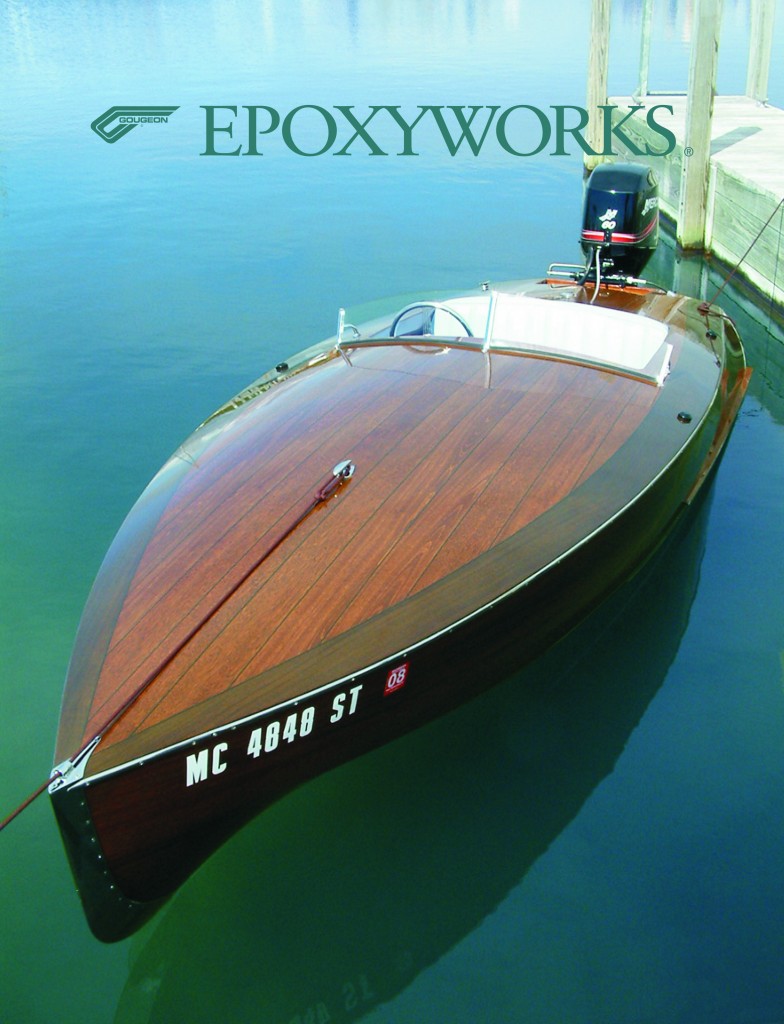

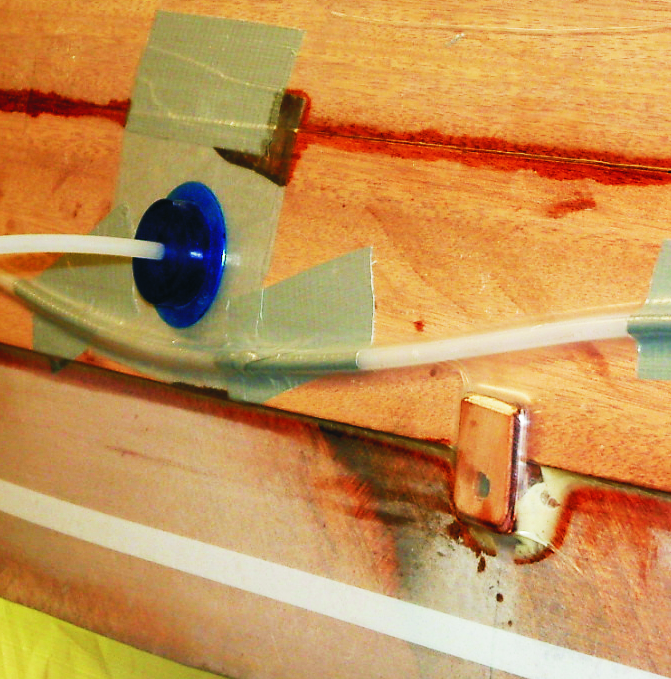

Building, restoration, and repair with epoxy The RASCAL ProjectBy steve gembrowski. Cover Photo: Steve Gembrowski spent 10 years building the Ken Basset designed RASCAL, a mahogany runabout. Fifteen years! Not that it took 15 years to build; it was more like a year and a half. I first saw a photograph of RASCAL and decided right then, if I ever build a boat, this is the one. RASCAL was a new design by Ken Basset for a modified V-bottom 14’10” runabout with a beam of 5’4″ and hull weight of 420 pounds. For the next 15 years, RASCAL became one of those projects sitting on the back burner, waiting until I had enough time and money to comfortably build her without having to compromise on engine, equipment or material. I’m sure plenty of builders out there can relate. My first step was to set the standard to which the boat would be built. Considering the time and money investment, the boat design, and the need to push my own skills, I set the bar high: Van Dam quality should do it. Van Dam Custom Boats is a builder of fine mahogany boats in Boyne City, Michigan, whose 100 mph, 32′ runabout, Alpha-Z , was featured in a cover story in Epoxyworks 14 . Pre-coating Rascal’s componentsFrom the beginning, I sanded and triple-coated all components with WEST SYSTEM® epoxy prior to assembly. This process seemed to take forever, but I can only imagine the nightmare it would have been to coat and sand around all the frames and stringers, all those tight little areas up in the bow, while standing on a milk crate and bending over the sheer rail. Then to repeat it three times. The whole project would have ground to a halt right there. Pre-coat. You’ll save time in the long run. I purchased LVL (Laminated Veneer Lumber, which looks like plywood 2×10) from the lumberyard to use as a strongback, set up the framework, and then turned my attention to the 120+ notches that would need to be cut in the frames to accept the Sitka spruce stringers. I made up a simple jig, a plywood plate approximately 4″×6″ with a rectangular hole cut in the center. The opening in the plate was centered over the notch location and screwed to the edge of the frame. I placed a guide bushing on my plunge cut router, adjusted the depth, and cut each notch in three passes. Back-up blocks were clamped to each frame to avoid chip-out. If you bevel the frames first, the bottom of each notch will automatically be cut to the same angle. However, I chose not to do this at this time and used a chisel to bevel the bottom of each notch, using the stringer as a guide. I also used this method to cut the notches in the white ash stem. After a little practice, I found I could install a complete stringer in about 25 minutes. Since the stringers were so closely spaced, I faired the entire framework with a board sander and an 8″ Dual Action (DA) sander with 40-grit, then 80-grit sandpaper. Then I coated all contact surfaces with epoxy.  Rascal’s framework is faired and ready for plywood. Frames and stringers were coated and sanded before they were assembled. Installing plywoodThe bottom was covered with ¼” okoume plywood and the topsides with 1 8″ okoume plywood. This layer was epoxied and stapled in place with ¼” crown staples. I shot each staple through a piece of braided nylon handling material (used to band lumber together for shipping). This allowed for quick staple removal by simply grabbing the tail end of the strap with a pair of pliers and giving a quick sharp tug 90° to the hull surface. Caution: wear your safety glasses as some of the staples will go flying. I again faired the hull and applied two coats of WEST SYSTEM epoxy.  The finished hull interior before the floor and deck were installed. The bottom was covered with ¼” okoume plywood and the topsides with 1 8″ okoume plywood. Vacuum bagging the mahogany planksNow the hull was ready for the ¼” Philippine mahogany. The plans called for the planking to be stapled along its edges approximately every 3″. In my mind, I envisioned a wooden boat that looked as though it had been assembled on a giant sewing machine. The next best thing was to try to match up about a thousand hole plugs, still not what I was looking for. I wanted a blemish-free surface totally free of fasteners. The only way to clamp the planking without making any marks was to vacuum bag it in place. Great…sounds simple enough, but how to bend the plank and hold it in alignment while setting up the vacuum? I would have to devise some type of non-penetrating fastener.  The bottom and topsides are faired and coated, ready for mahogany planking. The fasteners ended up looking like 1″ by 1½” mirror clips, similar to those used to hold your bathroom mirror to the wall. These clips were made from scrap plywood, and since they would be under the plastic, the top edges were rounded off with a sander. I found that once one plank was butted tightly against another, using these clips along the “loose” edge was all that I needed to secure the plank. Prior to gluing and mounting the plank, I ran a strip of ½” double back tape around the perimeter of the plank being installed and made sure to seal down all the edges and overlaps tightly. Then I glued and clamped the plank. I then took a piece of ¼” nylon tubing and drilled small holes in it every 3″. I taped this loosely along the length of the plank. The tubing allowed the air to be removed from the extreme ends of the bag and was reusable. Somewhere along the length of this tubing, I wrapped a piece of landscape fabric and taped it in place to form an “air bridge” from the tubing to the suction cup or vacuum port.  Each ¼” mahogany plank on the hull was clamped using vacuum bagging to avoid staples holes. An old dehumidifier compressor was rigged to pull up to 22″ Hg .  A closeup of the vacuum port and the clip used to hold the individual planks in position until the vacuum took over. I used builder’s plastic for the bag. (Note: use the clear plastic, not the milky white variety as this type is too slippery.) This plastic does not stretch very much, so I had to get real creative when taping the end of the bag. After the bag was in place, I made a small “x” cut in the plastic at the fabric location and covered it with the suction cup. Then I started the pump and checked for leaks. I had forgotten to mark my frame and stringer locations on the plywood and would occasionally miss the frame with the screw, causing a leak. By the time I found this out, I was already committed to the job and needed to plug the leak. To do this, I crawled inside the hull, listened, and then ran my finger along the frame hull joints until I found the leak. Then I packed the leak full of plumber’s putty or bubble gum, whatever I could come up with. After the epoxy cured, I cleaned up the plank edge with a trim router and moved on to the next plank. To supply that suction, I needed a vacuum pump. After searching the internet, I found several commercial units, ranging from $100 to $300. I knew someone had to have a cheaper solution. One kit-plane builder had the answer. Turns out that the solution had been sitting in my garage for years. I had an old Kenmore™ dehumidifier. The fan motor was burned out, but the compressor was still good. On the opposite side of that compressor was a vacuum, and that’s what I was interested in. I have had this unit pull up to 22″ Hg (inches of mercury), which is over 1,600 lb per sq ft. (To find out how to build a vacuum pump, visit The Cheap Little Sucker . Read all the links as they tell you what to look for when choosing a compressor. A good source for parts, vacuum gauge, suction cups, double-back tape, etc. is McMaster-Carr ; they offer fast service and excellent prices.) Rascal’s interiorDuring the winter of 2004-2005, I constructed the interior, disassembled it, and brought it into the basement for finishing. I chose Interlux Goldspar™ polyurethane varnish for two reasons: 1) I wanted the scratch resistance of the hard finish and 2) Since dust was a constant problem, the hard finish allowed me to wet sand all the parts and then use automotive products to rub out and polish the final finish. I lost some of the high gloss, but I also got rid of the dust flecks. This was a lot of extra work but worth it. I started sanding with 600-grit paper on a rubber block, very wet, then 800-grit, and finished with 1200-grit. All sanding and polishing have to be done within a single coat of varnish; if you sand through to a previous coat, no amount of polishing will make it blend and you will need to re-coat.  Rolling the hull to begin work on the deck was easy enough for three guys. Deck construction used the same schedule as the topsides. The caulked seams were filled with WEST SYSTEM epoxy thickened with 406 Colloidal Silica Filler and then darkened with 423 Graphite Powder. This mixture was piped into each seam with a zipper-seal bag with a corner snipped off. Next, all deck hardware and stainless steel trim were fabricated, fitted, and installed. After the windshield brackets were installed, patterns were made for the ¼” Plexiglas™ windscreens.  After Rascal’s floor was installed, the deck was framed. Spruce stringers will support 1 8″ Okoume plywood.  After a slight bit of fairing, the ¼” mahogany planking was installed. By using the right-sized braces, the roof provided some strategic clamping pressure. When I was satisfied with all the fits, I removed everything and sent the windshield brackets and stem-head fitting off to the chromer. Be sure to send out this type of work as soon as possible; my work took five weeks and one part had to be sent back to be redone. Needless to say, that part was the last thing installed on the boat before launch. Finishing RascalTo finish the hull, I used Minwax™ oil stain, followed by a 6 oz layer of glass cloth and five coats of epoxy. Then I used six coats of Epifanes™ no-sand varnish and finished with two coats of Epifanes spar varnish. I found that I had to plane the sheer very carefully as the glass did not adhere as well as I would have liked. For that reason, I would not recommend the use of the Minwax oil stain under the epoxy. I used the same stain on the deck and there elected to go with an all varnish finish, 11 coats in all. The RASCAL is a real head turner and gets a lot of attention wherever she goes. She took 1st place in the contemporary classic division at the 2005 Presque Isle Harbor Wooden Boat Show. The 4-stroke was initially a little heavy, which I corrected by mounting a hydrofoil to the engine. This made the trim much more effective throughout its range. Handling is very solid and predictable, with a top speed somewhere near 50 mph. Not bad for a fuel-sipping 60 hp motor. Is she Van Dam quality? In my opinion, not quite. Then again, I’ve always been my own worst critic.  Rascal. Cover story, Epoxyworks #24  | |

IMAGES

VIDEO

COMMENTS

The Rascal 14 is a recreational sailboat, built predominantly of fiberglass, with teak wood trim. It has a fractional sloop rig with black-colored, hard-coated aluminum spars and a tabernacle-mounted mast.The hull has a spooned plumb stem, a vertical transom, a transom-hung rudder controlled by a tiller and a retractable centerboard mounted in an enclosed trunk.

A boat with a BN of 1.6 or greater is a boat that will be reefed often in offshore cruising. Derek Harvey, "Multihulls for Cruising and Racing", International Marine, Camden, Maine, 1991, states that a BN of 1 is generally accepted as the dividing line between so-called slow and fast multihulls.

New Member. According to Harry Milling an employee and sailmaker for Ray Greene, Rascal and its bigger brother Rebel (16) were originally manufactured by Rebel Industries in Jackson, Michigan. Ray Greene was doing a college thesis in 1948 in conjunction with Owens Corning using honeycombed fiberglass.

Rascal 14 is a 14′ 5″ / 4.4 m monohull sailboat designed by Ray Greene and built by Ray Greene & Co. starting in 1961. ... The higher a boat's D/L ratio, the more easily it will carry a load and the more comfortable its motion will be. The lower a boat's ratio is, the less power it takes to drive the boat to its nominal hull speed or ...

The Rascal 14 is equipped with a centreboard keel. A centreboard keel is a pivoting lifting keel, allowing to sail both coastal and inland waters. The boat can sail close to the beach as the draft is just 0.28 - 0.38 meter (0.92 - 1.22 ft) dependent of the load.

RASCAL 14 Sailboat Data Hull Type: Centerboard Dinghy Rigging Type: Fractional Sloop LOA: 14.42 ft / 4.40 m LWL: 13.83 ft / 4.22 m S.A. (reported): 121.00 ft² / 11.24 m² Beam: 6.00 ft / 1.83 m Displacement: 400.00 lb / 181 kg Max Draft: 3.00 ft / 0.91 m Min Draft: 0.92 ft / 0.28 m Construction: FG First Built: 1961 # Built: 3000 Builder: Ray ...

Boat Name: Rascal 14: Manufacturer: Ray Greene: Hull Type: Daysailor: LOA: 14'5" (4.4m) Beam: 6'0" (1.83m) Weight: 400 (181.8kg) Ballast (kg) Keel Type: centerboard

Standard features. 14 Rascal by Spindrift 1980. One Design Centerboard Dinghy Fractional Sloop Rig Seats 4 adults. 6 Beam 3 Draft. ADDITIONAL: 14 Fractional Sloop Rig Mast Height 24 High Performance Features Generous Storage Under Foredeck Hand-Laid Fiberglass Exterior One Design w/Large Fleet Enclosed Bow Locker Foam Flotation Under Seats ...

Description: Sailing my 1960's vintage Rascal sailboat on a late summer afternoon. I would like to have captured some more exciting footage but this particu...

The Rascal 14 is a recreational sailboat, built predominantly of fiberglass, with teak wood trim. It has a fractional sloop rig with black-colored, hard-coated aluminum spars and a tabernacle-mounted mast. The hull has a spooned plumb stem, a vertical transom, a transom-hung rudder controlled by a tiller and a retractable centerboard mounted in ...

1960's Rascal 14' $1250. Length: 14' Beam: 6' Draft: min .92'/max 3' Hull: Fiberglass. Motor: No. Trailer: Yes. Description: A centerboard dinghy built by Ray Greene & Co. This model pre-dates hull identification numbers but it is likely from the 1960's. Perfect starter sailing vessel for a kid. Rascal come with sails and needed ...

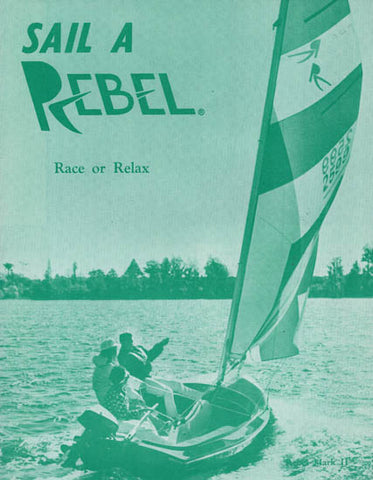

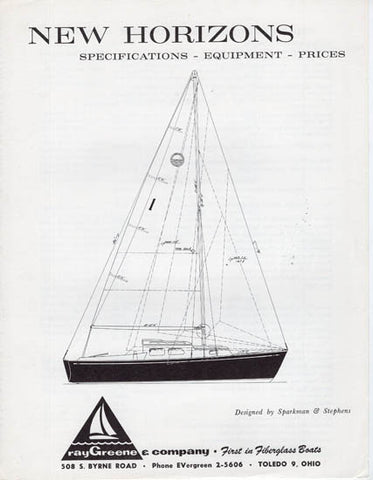

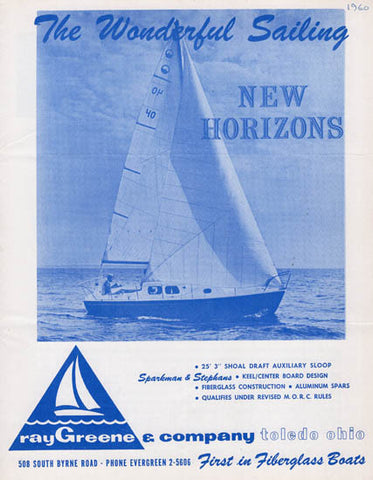

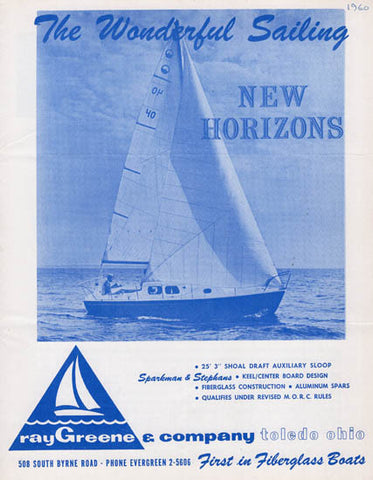

The company began with small sailboats. The most notable of these was the 16' REBEL. In 1957 the S&S designed NEW HORIZONS was introduced which became an instant success with almost 30 orders placed at the New York boat show of that year. ... RASCAL 14: 14.42 ft / 4.40 m: 1961: REBEL 16: 16.10 ft / 4.91 m: 1948: RHODES 22 CONTINENTAL: 22.00 ft ...

Location: Pennsylvania. Boat: 1974 Ray Greene Rascal II. Posts: 10. 1974 Ray Greene Rascal 14 Shakedown Cruise. I took my 14' Ray Greene Rascal out today on a local lake for a shakedown cruise to see what could possibly go wrong. Nothing terrible happened but I have a few questions that someone might be able to answer. 1.

Vixen. 1963 • 3.1 m. Founded by Ray Greene, one of the pioneers in the development of fiberglass boat construction. The company began with small sailboats. The most notable of these was the 16' REBEL. In 1957 the S&S designed NEW HORIZONS was introduced which became an instant success with almost 30 orders placed at ...

Rascal, a 14'10" outboard runabout that you can build in the backyard, strives to capture the cachet of big mahogany speedboats—without their mechanical complications and great expense. Designed and built by Kenny Bassett, Onion River Boat Works, RASCAL offers more bang for the buck than just about any other runabout a father and son ...

Original Manufacturer / Promotional Brochure. Date: 1960s Pages: 4 in B&W Size: 8.5 x 11 opens to 11 x 17 Condition: C8

Go to Sailing Texas classifieds for current sailboats for sale. Rebel Rascal 14, 1980. Great condition. Has Quantum sails main and jib, excellent condition. loa is 14 ft 5 in. beam 6 ft. draft board up is 6 in. board down is 3 ft 6 in. 140 sq ft of total sail area.

1981 14' Spindrift Rascal. Golden, Colorado, United States. Listed Oct 2. Expired. $2,100 USD. Save. Share. Share. SMS. Email. Facebook. Twitter. Pinterest. Print. More. Photos; Description; ... The higher a boat's D/L ratio, the more easily it will carry a load and the more comfortable its motion will be. The lower a boat's ratio is, the ...

Great company and staff! 2001 Bay Stealth 2230BSVL 22' Center Console - Florida (#364845959996) See all feedback. Find many great new & used options and get the best deals for LF - 1962 Ray Greene Rascal 14'5" Sailboat & 1985 Shorelander Trailer - Michigan at the best online prices at eBay! Free shipping for many products!

I first saw a photograph of RASCAL and decided right then, if I ever build a boat, this is the one. RASCAL was a new design by Ken Basset for a modified V-bottom 14'10" runabout with a beam of 5'4″ and hull weight of 420 pounds. For the next 15 years, RASCAL became one of those projects sitting on the back burner, waiting until I had ...

You must be logged in to create new topics. Log In. Username: