Repairing Fiberglass On Boats (Complete Beginner’s Guide)

Fiberglass boats are arguably the best kind of boats you can own. They’re lightweight, fun to use, and easy to maintain.

They’re even easy to repair, and in this post on repairing fiberglass boats, we’ll tell you exactly how to do just that.

Let’s get started!

Table of Contents

Fiberglass Basics You Should Know

Fiberglass is a wonderful material that can be used to repair all sorts of things.

Learn how to work with fiberglass, and you can repair boats, vehicles, bathtubs, and many other items.

You can even learn to create your own parts, canoes, and even coolers. An entire lifetime could be spent learning how to build and repair things using fiberglass.

But first, you need to know how fiberglass works as well as what it is. Fiberglass by itself is just a sheet of glass fibers woven or matted together. By itself, it is not hard, waterproof, or useful for anything.

However, once you apply a chemical resin to the fiberglass, it becomes waterproof, hard, and incredibly durable. It also remains lightweight, which makes it great for applications such as aircraft, automobiles, and boating.

The type of resin you use, the type of fiberglass you use, and the core material you use will determine just how hard and durable the constructed fiberglass becomes.

Types of Fiberglass Cloth

There are many different types of fiberglass cloths out on the market today.

Some of these cloths include chopped strand mat, biaxial mat cloth, woven roving cloth, continuous roving cloth, carbon fiber cloths, and the list goes on and on.

This being said, there are two types of fiberglass cloths that you’ll be working with:

- Fiberglass fabrics, or cloths

- Fiberglass mat.

The fiberglass fabrics will be your main structural material, but you may end up using a fiberglass mat to help you work around turns and to help waterproof low-stress areas like the live wells.

With these fabrics, you’ll also have different weights.

These weights will help determine how thick and strong the material is. Popular boating fabric weights are 10 ounces, 6 ounces, 4 ounces, and 1.5-ounce cloths. These fabrics are sold by the yard and generally come in widths between three and five feet.

The type of fiberglass fabric you choose will be determined by the application you’re using it for.

Also, lighter cloths can be applied in multiple layers, so if you need more reinforcement, you can always combine a 4-ounce cloth and a 6-ounce cloth in two different layers to provide the thickness and strength of a similar 10-ounce cloth.

Types of Resin

There are a lot of different resins out on the market these days, but the two you’ll most likely be working with are either epoxy resin or polyester resin. Epoxy resin is more expensive than polyester resin, but it is often considered stronger. It is also more versatile as the epoxy resin will bond well over polyester resin, but polyester resin may not work well over an epoxy.

This being said, different epoxy materials will work better with different core materials.

For example, the polyester resin will melt some foams and plastics. I found this out the hard way when I mixed some epoxy resin up in a plastic cup. The resin started leaking right through the bottom of the cup, and I was very thankful that I had decided to play with the fiberglass outside.

Some other types of resin you might run into are polyurethane resin and silicone resin. These resins are even more expensive than epoxy resin, and it doesn’t really make sense to use them for boat repairs anyway.

Core Materials

The core material is just the material that is encapsulated by the fiberglass cloth and resin. Core material on boats is usually balsam wood or a foam core. However, almost any material can become a core material.

For example, I’ve applied several different types of fabric with polyester resin over the top of pieces of cardboard. The fiberglass and resin are so strong that it turns the cardboard into a hard shell that you can use to make many different things, including small boats.

If you ever need to do a small one-off project that does not require structural support, think about using cardboard as a cheap and easy alternative to creating a mold or using traditional core material.

This being said, your best bet is to use a core material that is meant for your particular application. For obvious reasons, being out on the water in a damaged balsa wood and fiberglass boat is a whole lot safer than being out there in a damaged cardboard boat.

Also, keep in mind that you don’t always need a core material. Sometimes you can create a mold that simply holds the fiberglass and resin together until they dry and become components themselves. Many fiberglass hulls are built using molds that consist of a thick layer of fiberglass and resin, and they are designed to be very strong with many layers of built-up woven fabrics and mats with no core material.

Camper shells are also built this way without any core material. If you’re curious about what this looks like, just do a quick search for fiberglass campers on this website, and you’ll see plenty of examples.

When you’re doing repairs on an existing fiberglass boat, you may not be using any core material either.

This is especially true if you’re just repairing a crack or hole in a non-load-bearing area. In this case, you’ll just be applying cloth over the crack and sealing it with resin.

How Is The Fiberglass Applied?

There are a few different ways that fiberglass can be applied.

- Roll it on with a paint roller

- Paint it on with a brush

- Spray it on with a spray gun.

When doing fiberglass boat repairs, you’ll most likely be painting or rolling it on in small batches.

The way you’ll do this is you’ll mix up a small amount of resin that you can successfully paint on over the fiberglass within about 15 to 20 minutes. This is about how much time you’ll have before the resin begins to dry and harden. If you mix too much resin, you’ll end up wasting it, so it’s important to start small until you get a feel for working with it.

Also, keep in mind that all of your fiberglass should be laid out over the area you’re repairing before you begin mixing your resin.

Once your resin becomes active, you won’t have time to go back and cut out pieces of fiberglass.

General Tips for Working with Fiberglass

As we alluded to earlier, fiberglass must be mixed before it can become active. This is usually done with a hardener. The manufacturer will tell you just how much hardener needs to be added to the resin.

Gel coats can also be added to the resin, but this shouldn’t be done until you are on your final layer.

If you apply the gel coat too early, you’ll end up having to sand the layer down before you can add any additional layers.

Also, keep in mind that fiberglass resins are meant to be used at different ambient temperatures. If the temperatures are too high or too cold, the resin will not cure properly.

You’ll know the resin didn’t cure correctly if the fiberglass feels tacky afterward.

Safety Tips for Working with Fiberglass

Fiberglass resins and hardeners can be toxic, and it’s important to keep them off of your body and out of your lungs.

Personally, I only work with fiberglass outside, but any well-ventilated area will do.

Also, if you’re working with polyester resin, you’ll want to wear a respirator. Not only is polyester resin toxic to breathe, but it smells awful. The smell is so bad that I won’t even leave the closed bottle of polyester resin inside my house for fear that it will make the house smell bad.

You don’t want to get resin on your skin or your eyes either. Wear protective clothing, gloves, and safety glasses to prevent this from happening.

For additional protection, you can also get a lotion that will work to coat your hands. This way, if the resin gets through your gloves, you’ll have an extra layer of protection between the resin and your skin. If the resin does end up getting on your skin, be sure to wash it off immediately.

People have been known to develop allergies to epoxy resin, and once you get this allergy, you’ll never be able to be around epoxy resin again.

Fiberglass Buying Tips

- Always buy fiberglass by the roll. Unfortunately, many people will try to sell you folded pieces of fiberglass because it is cheaper and easier to pack, ship, and store it this way. Sadly, folding fiberglass cloth can weaken the strands, so when you buy fiberglass that is folded, you’re buying cloth that is already damaged.

- Buy the hardener with the resin. It’s always easier just to buy the hardener and gel coats with the resin. Different resins will need different amounts of hardener, and the manufacturer will usually sell the two as a kit.

- Get good mixing cups. A poorly mixed resin will not work properly. Get good mixing cups so that you can accurately mix the resin and get the most benefit from it.

- Buy it locally (at first). A local marine store owner can often offer you valuable tips for working with fiberglass, and they can help tell you where you went wrong when you run into trouble. You’ll probably end up paying a bit more for your resin, but you’ll often end up with some good and free advice.

- Buy the right fiberglass for the job. When you go to buy fiberglass, you’ll notice right away that chop strand mat is dramatically cheaper than all of the other types of fiberglass. There is a reason for this. Fiberglass mat is not very strong, and it can be difficult to work with. Only use fiberglass mat when the job specifically calls for it. Resins are expensive, so there isn’t any point applying them over inferior fiberglass cloths.

Repairing The Hull

Before you decide to repair your own boat hull, you may want to do a reality check.

Is the boat hull severely damaged? Is your boat an ocean vessel that is going to be put under a lot of stress?

If you answered yes to these questions, you might want to save this project until you have a lot more experience with fiberglass repair. In this situation, a bad repair job could put your life in jeopardy, so the money you save will never be worth it.

This being said, there are a lot of small hull repairs that you could tackle yourself without much risk. For example, a small hole in a small boat that you only take out on the lake shouldn’t be too much for you to handle. Small cracks or holes in the areas above the water line might not be a big deal either, but please use your best judgment.

Repairing Holes in The Hull

To repair a hole in the hull, you may need to get some new core material. Try to match the new core material with the existing core material. Make sure the remaining core material is dry.

Once you have the core material, you’ll need to fit it into the hole. Next, measure and cut your fiberglass cloth. Lay the fiberglass over the area, using fiberglass tape if you have to. Once everything is in place, mix up your resin and apply it over the damaged area. You may need to do multiple layers.

For professional repairs of ocean-going hulls, the surrounding fiberglass is ground back on a slope of 1:12 to make a large area to be repaired; a 1/2″ thick fiberglass structure would be ground back 6″ in every direction from the hole.

The patch is then built-up with increasingly larger pieces of fiberglass mat and resin. Again, you need experience before trying this.

Your final coat should be a gel coat that matches the color of your boat.

Alternatively, you could repaint the boat after the repairs have been made.

Repairing Cracks

Be careful when repairing cracks in your hull, as they could be a sign of bigger structural issues.

For example, a balsa boat with cracks in it could have rotten wood inside the hull.

However, if you just see some cracks from when you accidentally backed into a tree last week, feel free to try to take on the repairs yourself. You probably won’t need any new core material, but you will need some fiberglass and some resin to patch up the crack.

Measure, cut, and layup your fiberglass before mixing your resin, and you shouldn’t have any trouble with the repair.

One thought to keep in mind with a repair like this is that you’ll probably spend more time sanding and painting than you will be doing the actual repairs. The more time you spend sanding, the better the boat will look when you’re done.

Repairing The Floor and Deck

The first thing you should do before making any repairs to the deck or the floors is to check to see how severe the damage is.

Often-times, decks and floors are made from wood, and if they are spongy or have holes in them, the wood is probably rotten underneath.

Before making any repairs to the fiberglass, you’ll need to take out this rotten wood and replace it. What seems like a small repair, in the beginning, can often end up being an extensive repair. If you don’t believe me, just look at all the free “project boats” listed on Craigslist.

Oftentimes you’ll see that the person giving it away received the boat for free himself, thinking that he could do the repairs and get a free boat.

Once he started to tear the boat apart, he realized just how much work and money would be needed and decided to give up on it.

Once you do know what you’re in for, start replacing the decking and flooring, making sure to keep the materials dry until they are encapsulated with new fiberglass and resin. Also, be sure to make a note of where the different pieces of hardware are connected to the deck, as you’ll need to put them back on when your repairs are complete.

If you’re careful, you can use the old decking that you pull off the boat as a template for creating your new decking.

Once your new flooring is complete, secure it to the boat and begin placing the fiberglass cloth over it. Be sure to use a good amount of fiberglass as the decking will need to be strong enough to support people walking over it. Mix up your resin and apply it in small batches.

If you have a large area to do, you’ll be tempted to make larger batches but don’t do this as you’ll only end up rushing the job or finding the resin sets up prematurely.

Flooring Alternatives

Another thought to keep in mind is that you don’t always need to replace your wood flooring with wood. Some people will skip the fiberglass altogether and simply install an aluminum floor instead.

This can be useful in certain applications but not very useful in others, so you’ll need to analyze your particular situation before you decide to make any changes.

If you do decide to skip the fiberglass, just be careful to find out what changes this will have on the weight of your boat. Making a heavier boat could reduce your boat’s max capacity and affect the way your boat sits in the water.

Repairing The Keel

The keel is an integral part of a boat. On a sailboat, the keel keeps the boat upright in the water and helps to keep it stable in heavy winds.

Being at the bottom of the boat leaves it much more vulnerable to scraping the ground and running into rocks. For this reason, a keel can often take damage even when the rest of the boat remains trouble-free.

The question is, do you want to repair this damage to the keel yourself?

If you have a small recreational boat that you can easily bring up on land, I’d say go for it. You can flip the boat over in your backyard and spend as much time as you need applying a new resin and gel coat to the keel.

For boats that you know will be scraping the bottom again, you may want to apply a keel guard as well. This will help protect your keel, so you don’t have to constantly make repairs each season.

Repairing The Transom

A solid transom will ensure that your boat’s engine doesn’t fall into the water. If you’re going to make this repair yourself, make sure you’re prepared to do it properly.

Oftentimes the core of the transom needs to be replaced, and you’ll want to make sure you replace it with a material that is as strong or even stronger than the original. This is especially true if you’ve upgraded the original boat engine to something bigger and heavier.

Once you’ve replaced the core material, the steps for making the repair remain the same.

Apply your fiberglass boat cloth and use as many coats of resin as you need to get the job done.

This repair includes a lot of hard edges, so you may need to overlap your layers of fiberglass at the top to get a good seal. Take your time and make sure the fiberglass wraps properly, or you’ll end up having to do a lot of sanding at the end of the job. Also, be careful to account for where the engine will be mounted so that you can match the hardware appropriately.

Repairing Hatches

Hatches are easy repairs, and they’re great for getting started with fiberglass.

When replacing a hatch, use the existing hatch to make a template for the new one.

The new hatch should be easy to make, and you won’t have to use a lot of thick fiberglass cloth since it won’t be the main structure of the boat.

The main thing to keep in mind when doing this repair is that the hatch will need to be sealed properly afterward. Oftentimes, people will do a great job repairing or replacing the fiberglass hatch, but they won’t seal it properly afterward, and they end with a leaky hatch.

Repairing Scratches

Scratches in the fiberglass usually don’t require extensive repairs, and the cost is usually minimal.

The reason for this is that the fiberglass does not need to be replaced, and the core material is not yet affected.

Unfortunately, some deep scratches in the gel coat can end up creating a lot of prep work. You’ll end up needing to do a lot of sanding to get the boat to look new again.

You’ll also need to do a good job matching the color.

If your boat is new, this may not be a problem, but if your boat has been out in the sun for a while, you won’t be able to use the original boat color as it will end up being too dark.

You’ll have to color match the boat, or you’ll have to resign yourself to painting the entire boat over again.

DIY Costs vs. Professional Costs

Doing repairs yourself will usually save you money, and they can sometimes even save you on time.

However, some jobs are too big to be done by beginners, and some jobs just take too much time for the DIY repair to be worth it.

I’ll try to give you a breakdown of some of the costs here so you can decide for yourself whether or not the repair is worth paying for or doing yourself.

Example costs from FiberGlassSite.com:

- 6-ounce fiberglass cloth 50” wide and 5 yards long. – $25.00

- 1 gallon of polyester resin with hardener. – $39.00

With this much cloth and resin, you could do a lot of small repairs of cracks and holes.

A simple hole or crack repair might cost you $50.00 each, so you’d definitely save money on smaller repairs, and you may even have some extra fiberglass left over for the future.

For a balsa core deck repair, you might want ¾ inch core. This costs about $50.00 for a 2’x4’ piece. You’ll also need a 10-ounce fiberglass cloth and polyester resin.

This repair might end up costing you a couple of hundred dollars, but it could save you a thousand.

Foam core used for repairing heavy damage to the hull of a sea-going vessel will need to be very strong. Not only this, but you’ll need to consult with a marine technician to determine what the best combination of foam, resin, and fiberglass should look like.

Between material costs and consulting costs, you’ll end up spending thousands of dollars. You’ll also end up spending a lot of time, and you may devalue the worth of the boat since a buyer might not feel safe buying a boat that was repaired by an amateur.

In this case, you may be better off paying a professional boat repair company to do your repairs.

Final Thoughts

Working with fiberglass can be tricky, but it can also be a lot of fun.

Learn how to work with fiberglass, and you’ll find an almost endless number of projects to take on.

Just keep in mind that working with fiberglass is not cheap or easy to get into. If you decide to take on fiberglass projects, be prepared to spend some time and money doing so.

Also, be prepared to mess up a few projects while you’re learning.

Click to share...

Please verify you are a human

Access to this page has been denied because we believe you are using automation tools to browse the website.

This may happen as a result of the following:

- Javascript is disabled or blocked by an extension (ad blockers for example)

- Your browser does not support cookies

Please make sure that Javascript and cookies are enabled on your browser and that you are not blocking them from loading.

Reference ID: aa0be83e-74d6-11ef-b190-9f03b6013893

Powered by PerimeterX , Inc.

- Boat Repair

- Fiberglassing Tools and Supplies

- Woodworking

- Random Posts

- Shop Our Amazon Store For Fiberglass Materials And Supplies!

- Check Out Our Fiberglass Guides Here!

Structural Fiberglass Repair Part 1

- 0 Shares Share 0

This is part 1 of a 3 video series outlining how to repair structural damage to your fiberglass boat. Make sure to watch all 3 in order! Otherwise you will be totally lost 🙂 These video’s are leading into the gelcoat series which is coming!

Please ‘Like’ or ‘Share’ above and join the discussion below in our comments section!! Also, please remember that there are extended ad-free versions of these video’s available for Patreon supporters! Please click below to find out more.

Materials, Tools, & Suppliers

- 1.5oz CSM Fiberglass

- 1708 Bi-Axial Fiberglass

- Polyester Resin

Join the discussion 12 Comments

Your the best.

On the grinder, what kind of grinder wheel do you use? Thanks for the videos and keep ’em coming. I need to learn more!!!

It’s a 36 grit ‘flap disk’.. I’d have to look up the invoice for the brand, but I’m thinking that a quick google search should pull something up for ya ;-)… If not, let me know. Only thing I can think of to note would be to make sure that the arbor size of the wheel fits your grinder..

Hello I have a 18 foot fiberglass boat (hydrostream v-king) that has six holes in a 1.5 foot square area, the holes are the same size as the one in the video. my problem is if i repair the holes the way you show in the video most of the repairs will be over lapping each other is this ok or should I remove the section of the bottom and replace it ?

You should be fine to overlap the repairs. Since it’s such a small area I would probably do the final couple glass layers over the entire area, then fair the repair for gelcoat..

I can’t do a two-sided repair as you suggest. I’m repairing a sailing dinghy, and the inside is inaccessible – a very narrow space between the hull and cockpit.

I was all set to buy the laminating resin when I realized I won’t be able to coat the inside with the mold release. In this situation, it seems I must use the pre-waxed resin. Is that correct, or is there an alternative?

Hey Greg, I think I understand your situation but if you could please email (or post on Facebook) a couple pics of the repair area I’ll be able to give better advice 🙂 Thanks!

Aloha Andy I have to say I have been in the composit industry for 20+ years and your videos are awesome. I know for me the understanding is super clear, but the way you go about explaining things is great for someone to tackle there own repairs and fiberglass project. Thank you for sharing your knowledge it is rare in our industry for people to be open and informative. Great job aloha Mike Storm maui, Hawaii

In repairs where there is no access to the interior surface of the hull would a repair completely from the outside not work fine… where you copy the thickness of the hull over say an circle area of say 8 inches in diameter with a taper around the hole so that succeeding larger pieces of biax and mat are used to match the thickness of the hull ?

I ask this as it seems to be published in West’s fiberglass pamphlet and other places using epoxy. I’m wondering if using only polyester to repair would require a stronger engineering approach…

Also, I wonder if you only applied a “form” piece of plastic glued to the inside surface of the hull covering the hole as a stop gap for your repair… then ground out the entire area the thickness of the hull in a gradual bevel and did the entire repair from the outside … would this not be just as strong as your illustrated method considering the pressures from use would be from the outside inward? … with water etc.

I really enjoy your website and youtube videos… thanks for such a good source for information. I’m wondering what bedding compound you use to re-bed older aluminum or stainless ports …. life caulk (polysulphide) over silicone I’m presuming…. comments welcomed.

Hey Andy – Your vidoes have encouraged me to get into fiberglass and gelcoat repair on my old sail boat that I wouldn’t have tried otherwise. I have also been sharing them with members of our yacht club and on sailing blogs. Really appreciate your great work!

Thank you very much Mark! I really appreciate it 😉

Leave a Reply Cancel Reply

Recent videos.

Recent Blog Posts

- There’s been a lot of changes with Boatworks Today over the past year!! November 28, 2022

- Getting your boat ready for Fall? Get a 5% discount on Totalboat products! September 21, 2019

- A New Fiberglass Guide And New Website! October 2, 2017

- Applying Gelcoat, Spray or Brush? November 18, 2013

- What’s been going on?? April 16, 2013

Legal Disclaimer

Because Boatworks Today, its owners or partners cannot control how the information provided through these videos is applied, we will not be held liable for any damages; incidental or consequential.

© 2024 Boatworks Today. | Developed by Fortiris Group LLC

I AM NOW AN ONLINE RETAILER FOR ALEXSEAL OFFERING SALES AND SUPPORT! HTTP://WWW.MILLERBOATWORKS.COM Dismiss

Step-by-Step Guide to Repairing Your Fiberglass Boat: From Small Holes to Structural Issues

Fiberglass boats are a popular choice for recreational boaters due to their durability and longevity, but even the toughest boats can experience damage from time to time. Whether you have a small hole from a stray rock, a drilled hole from installing hardware, or a larger structural issue, repairing a fiberglass boat can seem daunting. But with the right tools, materials, and a step-by-step approach, anyone can make a successful repair.

In this comprehensive guide, we will walk you through the process of repairing your fiberglass boat, from cleaning and sanding the surface, to applying fiberglass filler, gelcoat, and more. Whether you’re repairing a small hole or a large structural issue, we’ll provide you with the knowledge and techniques you need to make a professional-looking repair that will help extend the life of your boat. So, let’s get started!

Fiberglass boats are a popular choice among boaters due to their durability and lightweight nature. However, with time, use and exposure to the elements, your fiberglass boat may start to show signs of wear and tear, such as cracks, holes, and dings. In this blog post, we’ll take a look at the steps involved in repairing the bottom of a fiberglass boat, repairing a drilled hole, repairing a screw hole, and repairing large and small holes in the fiberglass boat hull.

Table of Contents

Repairing the Bottom of a Fiberglass Boat

- Clean the area: Start by thoroughly cleaning the damaged area with soap and water to remove any dirt, grease, or oil. Use a solvent-based cleaner if necessary to remove any stubborn stains.

- Sand the area : Use sandpaper to rough up the surface around the damaged area. This will help the repair material adhere better to the surface.

- Fill the area : Use a two-part epoxy resin to fill the damaged area. Mix the two parts according to the manufacturer’s instructions and apply a thin layer to the bottom of the boat using a putty knife.

- Smooth the surface: Use a plastic spreader to smooth out the surface of the epoxy resin. Make sure the surface is level and flush with the surrounding area.

- Sand the surface : Once the epoxy resin has cured, sand the surface to make it smooth and level with the surrounding area.

- Apply gelcoat : If the gelcoat on your boat is damaged, apply a fresh layer to protect the repair and give the boat a smooth finish.

Repairing a Drilled Hole in a Fiberglass Boat

- Fill the hole: Use a two-part epoxy resin to fill the drilled hole. Mix the two parts according to the manufacturer’s instructions and apply a thin layer to the hole using a putty knife.

- Smooth the surface : Use a plastic spreader to smooth out the surface of the epoxy resin. Make sure the surface is level and flush with the surrounding area.

Repairing a Screw Hole in the Boat Hull

- Clean the area : Start by thoroughly cleaning the damaged area with soap and water to remove any dirt, grease, or oil. Use a solvent-based cleaner if necessary to remove any stubborn stains.

- Fill the hole: Use a two-part epoxy resin to fill the screw hole. Mix the two parts according to the manufacturer’s instructions and apply a thin layer to the hole using a putty knife.

- Sand the surface: Once the epoxy resin has cured, sand the surface to make it smooth and level with the surrounding area.

Structural Fiberglass Repair

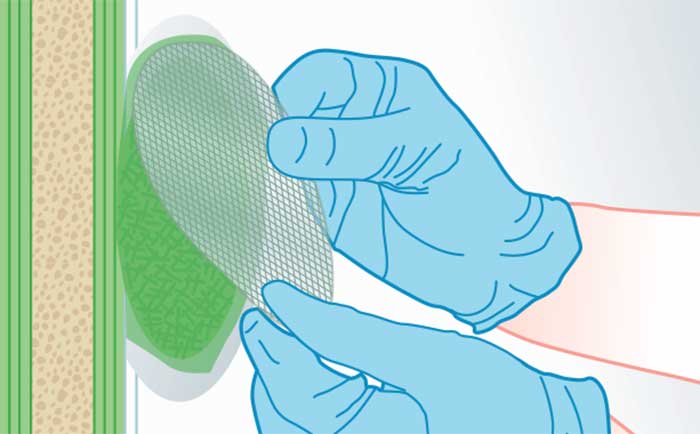

- Apply fiberglass mesh : Cut a piece of fiberglass mesh to fit over the damaged area and lay it over the surface. Use a two-part epoxy resin to cover the mesh and fill any gaps.

Repairing Fiberglass Boat Hull from the Outside

- Apply fiberglass cloth : Cut a piece of fiberglass cloth to fit over the damaged area and lay it over the surface. Use a two-part epoxy resin to cover the cloth and fill any gaps.

Repairing Large Holes in Fiberglass

Repairing small holes in the fiberglass boat hull.

- Apply fiberglass filler : Mix a small amount of fiberglass filler and apply it to the damaged area using a plastic spreader. Make sure the filler is level and flush with the surrounding surface.

- Sand the surface : Once the fiberglass filler has cured, sand the surface to make it smooth and level with the surrounding area.

In conclusion, repairing a fiberglass boat can seem intimidating, but with the right knowledge and approach, it can be a simple and rewarding process. Whether you have a small hole, a drilled hole, or a larger structural issue, by following the steps outlined in this guide, you can make a successful repair that will help extend the life of your boat and keep it looking great.

It’s important to remember that a proper repair starts with proper preparation, so take the time to clean and sand the surface, and use high-quality materials to make sure your repair is strong and durable. With a little patience and attention to detail, you’ll be able to make a repair that will make your boat look and perform like new. So, grab your tools and get started on your next fiberglass boat repair project!

Emily Smith

Emily Smith is a passionate sailor and travel enthusiast, who has spent the last 8 years exploring the world by boat. From the tranquil waters of the Great Lakes to the roughest oceans, Emily has sailed it all and decided to share the knowledge on Sailingbetter.com blog. With a keen eye for detail and a talent for storytelling, Emily offers readers an insight into the thrilling world of sailing and the beautiful destinations it can take you to. When she's not out on the water, Emily calls Chicago, Illinois home and enjoys sharing her love for sailing with others. Join her on her journey as she continues to discover new horizons and inspire others to live life to the fullest.

Recent Posts

Lagoon vs Leopard Catamaran: Which Sailboat Is Right for You?

Introduction When it comes to cruising on the open waters, catamarans have gained immense popularity for their stability, space, and comfort. Two of the leading catamaran manufacturers, Lagoon and...

How to Determine Sailboat Weight: A Comprehensive Guide

Introduction Sailing is a thrilling and adventurous activity that has captivated humans for centuries. Whether you are a seasoned sailor or a novice looking to set sail for the first time,...

- (678) 322-7877

- 9605 Jot Em Down Rd. Gainesville, GA 30506.

How to Repair Boat Fiberglass

Did you know you can repair holes in the hull or deck of your fiberglass boat? To make these strong and to near cosmetic perfection, visit a shop that specializes in boat fiberglass and gelcoat repair. A DIY enthusiast can also achieve good results with fiberglass and gelcoat repair. Learn the techniques and materials that are used to get the best results.

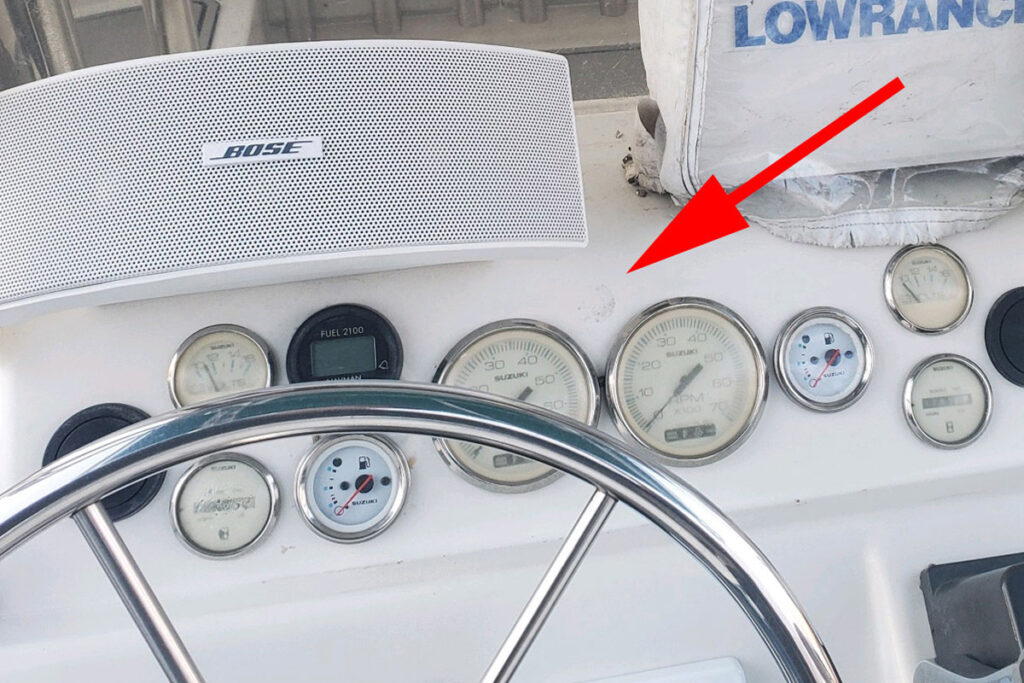

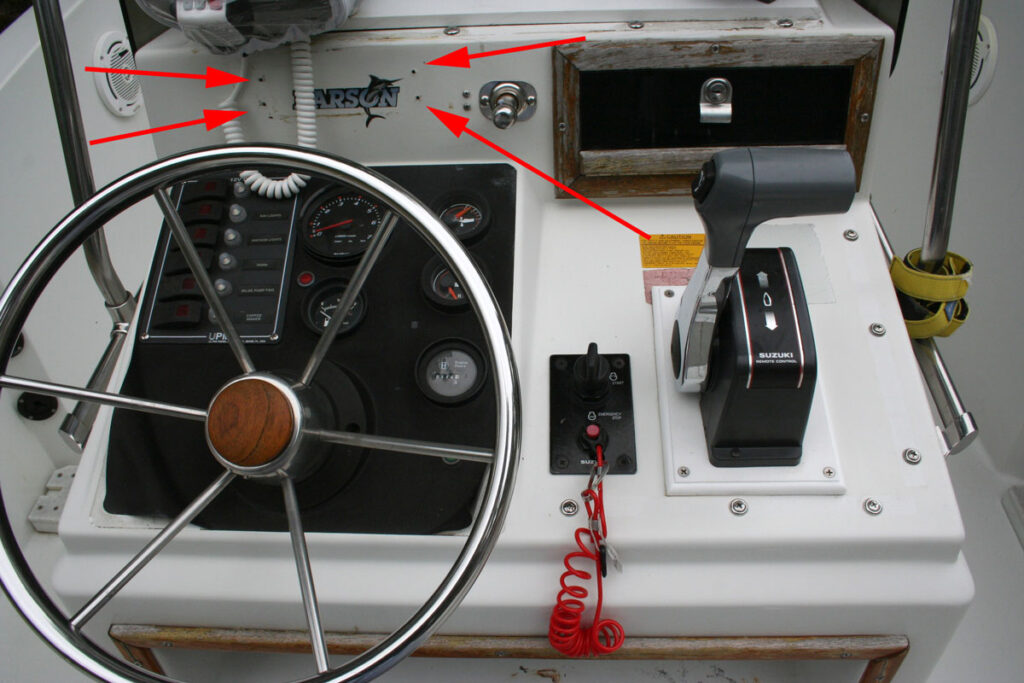

A hole in the side of this Boat was permanently repaired to cosmetic perfection by choosing the right fiberglass materials and applying the proper repair techniques.

What is Fiberglass and What Gives Fiberglass Strength?

Fiberglass is from two components: resin and fiber. It is called fiberglass because the structural fiber used is actually woven with tiny flexible strands of glass. The fiber is then saturated with resin, stretched into place, and when it cures through a chemical reaction, the result is a hard and durable material. The strength of the fiberglass largely depends on the weight of the structural fabric that is used. There are different weave patterns to the fabric that render it useful for different applications. The resin component is either polyester resin or epoxy resin. Epoxy resin is stronger. If the repair area is large and is in a high-stress part of a boat below the waterline, epoxy resin is the superior choice. This is because it has excellent bonding properties to an existing surface and is strong. Polyester resin is commonly used. However, one drawback is that it shrinks as it cures and thereby diminishes its adhesive qualities. This shrinkage is insignificant in small repairs, even in high-stress areas. But because of the shrinkage and reduced adhesion, there are limitations to using polyester resin for large repairs in high-stress areas. However, outside of large structural repairs, polyester resin is the material of choice and is used in the bulk of fiberglass repairs.

For small fiberglass repairs, polyester resin is used in combination with mat or chopped cloth mixed in resin to make a sturdy repair.

Fiber Choices For Fiberglass Repair

The most common type of fabric is plain weave cloth. It is easily recognized as it is woven at 90 degrees, and it looks like cloth. It comes in different weights, and a thicker cloth is stronger. One limitation of plain weave cloth is that it doesn’t conform to complex shapes or curves. It’s best applied on an even plane. For complex shapes and compound curves that require strength, the best fabric is modified twill. Its weave appears to be diagonal, but in reality, it is also woven at 90 degrees and is a looser weave with flexibility. It can conform to complex shapes without wrinkling. The most flexible fabric is called a mat. It has hair-like strands going in every direction. Mat is bonded with glue that dissolves in polyester resin, enabling it to conform easily to complex shapes or compound curves. However, it has less strength and is often used in cosmetic applications unless built up in many layers. Lastly is a fabric called roving. This is a fabric that has course bundles of strands in its weave. It is a very heavy fabric for the strongest of applications. It will be used in combination with layers of mat to give a smooth final surface.

Structural fiberglass cloth and cosmetic mat are used in combination with resin to make a strong fiberglass repair.

Repairing a Hole With Fiberglass

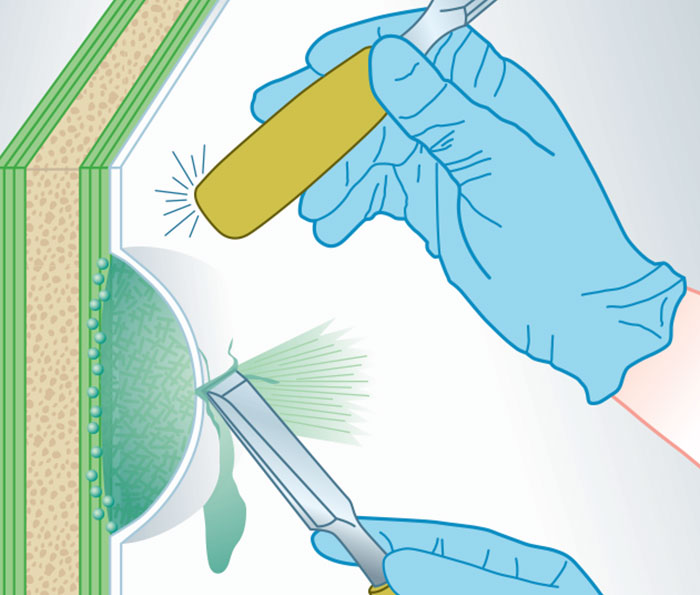

When repairing a hole with fiberglass, repairs are best made by access from both the inside and the outside of the repair. However, access from the interior may not always be possible because a floor or interior wall may block access. If it’s a serious structural repair in a high-stress area, you’ll have little choice but to cut a hole through the floor or wall to access the inside of the repair. However, doing a repair from the outside only is possible for small repairs or repairs in low-stress areas. The first thing to do is assess the damage carefully by cleaning the exterior with acetone. This will make hairline cracks evident, and you’ll want to grind all the way back until the crack terminates. First, using a 4-inch grinder with 80-grit sandpaper, grind or cut away any broken material in the perimeter of the hole that lacks structural integrity. Then with the grinder, taper the edges of the hole using a 12:1 rule. That is, taper back the edge of the hole at an angle that is 12 times the overall thickness of the fiberglass material.

Checkout marine product sales online for all your boat repair equipment.

To repair a hole, use a 4-inch grinder and coarse sandpaper to grind away any broken material that lacks integrity. Then taper back the edges of the hole.

If it’s a repair from both the inside and outside, the taper will be centered on the thickness of the fiberglass and taper back on both inside and outside, resembling the cutting edge of an ax. If the repair is done from the exterior only, then the taper will start at the bottom of the thickness of fiberglass and taper toward the outside, resembling the cutting edge of a carpenter’s chisel. Next, after the taper from the edge of the hole outward is complete, grind back toward the perimeter to where the hairline cracks ended. Now the entire repair area has been defined. Repeat the same on the inside of the repair if you’re doing a two-sided repair. Clean all surfaces with acetone to be free of dust so the resin will adhere.

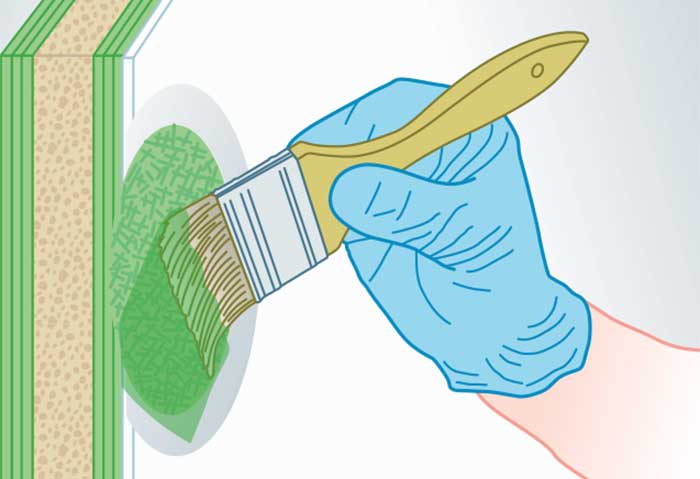

For a two-sided repair, next, you’ll cut a piece of fabric that extends to the outer margin of the repair. Mix up resin and hardener, and on a scrap piece of cardboard, lay your piece of fabric, and use a brush to saturate the cloth with resin. Turn the fabric over and coat the other side. Next, take the brush and apply resin to the interior repair area. Then carefully stretch the resin-soaked fabric over the hole, so it’s on a smooth plane and wrinkle-free. Use the brush to press out any air pockets, so the patch sits flat against the existing interior surface. Once the interior fiberglass patch has been set up and is somewhat hard, have already cut a piece of cloth or several layered pieces of cloth that will fill the thickness of fiberglass to near the surface plane of the exterior. The outermost layers will be a resin-soaked mat, so it will be smooth and not show the texture of the cloth.

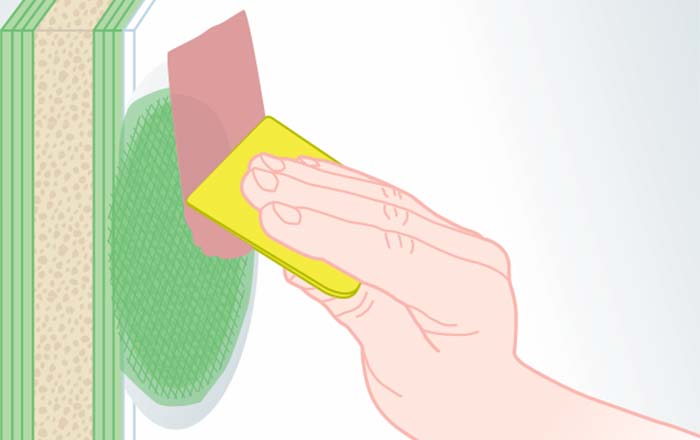

Let the patch dry. Once it is dry, grind down the high spots with 80-grit sandpaper until it is on the plane with the finished surface. At this point, clean off the sanded area, and assess the low spots. If there are still high spots, continue to grind them down. Next, you’ll use a resin that’s mixed with chopped strands of fiberglass. This is a cosmetic layer, as the structural layers are already in place. This will fill the low spots and bring the repair up to plane with the exterior surface. Once the chopped strand layer is set up and hard, grind down the high spots until in plane with the finished surface. The next step is to mix up what is referred to as “peanut butter .”This is resin and thickener and is the consistency of smooth peanut butter. Using a plastic applicator, apply the peanut butter resin mixture to give the final surface all the way to the perimeter of the repair. If it is a curved surface, use a metal, plastic, or plywood flex board to smooth the final contour. Once this layer is dry, grind it down so you’re perfectly on the plane with the exterior surface. Now there should only be some minor pits and pinholes to fill. Use a skim coat resin and hardener and apply using a plastic applicator. Once dry, sand to perfection using fine sandpaper.

Spray the Gelcoat

The Gelcoat is the shiny hard finish surface on the boat exterior. Once the color is matched, spray on the finish coats of gelcoat. Once the topcoat dries, use 600-grit wet sandpaper and higher to seamlessly blend the new gelcoat with the original finish. Lastly, use wax to give the final buff to make the repair invisible.

Gelcoat is the shiny cosmetic finish to Fiberglass repair. It is sprayed on and built up in multiple applications to create a glossy topcoat.

Repairing a Minor Chip or Gouge in the Gelcoat

In this case, the structural fiberglass has no damage, and it’s just the finish layer of gelcoat that needs repair. Grind the repair with a Dremel tool to expose clean fiberglass and bevel back the repair edge. Mix up the correct color of gelcoat with hardener, and take a small brush and create a slightly raised puddle of gelcoat that entirely fills the void and extends just past the margins of the repair area. Let the puddle dry hard, then using 600-grit wet sandpaper, sand until flush with the finished surface. On a flat surface, use a sanding block to create a perfect plane. End with a coat of wax to make the repair blend in perfectly.

Repairing fiberglass is a multi-step process. However, even the most unsightly damage from hitting a rock, bumping into a dock, or even a collision can be repaired to look just like new. Lakeside Marine offers professional boat fiberglass repair from minor dings to major structural repairs. We also handle fiberglass repairs for boat insurance claims, making the repair and insurance reimbursement process seamless. We even do boat modifications and restorations.

Lakeside Marine does fiberglass repairs for boat accident insurance claims, classic boat restorations, and custom high-performance boat modifications.

For professional results for your boat fiberglass repairs, call email [email protected] or go to our webpage and learn about our [fiberglass repair services], and read customer testimonials about how Lakeside Marine performed outstanding fiberglass repair while providing exemplary customer service.

Book a Boat Fiberglass and Gelcoat Repair

NEVER MISS A POST

Sign up for free and be the first to get notified about updates

Pre Winterization Maintenance Tips

Oct 27, 2022

Your boat served you well over the past boating season. However, with normal wear and tear, your boat requires attention. Maintain your boat as service needs arise, and keep its value and performance at its peak. Reasons to perform boat maintenance in the fall and...

Boat Fire Prevention and What to do in case of Fire

Aug 2, 2022

Boat fires are serious, and here’s how to maximize your safety. We discuss the common causes of boat fires, how to prevent them, and what action to take if a boat fire breaks out. What are the common causes of Boat Fires? Electrical fires Explosive gas or propane...

Spring Boat Checklist and Guide For Boat Maintenance, Repairs, and Upgrades

Nov 26, 2021

Every boat owner is excited for the spring launch. Visual inspections and on-time scheduled boat maintenance ensure a trouble-free season opener. Follow this boat-prep spring boat checklist and know that you’re prepared and ready to throw some spray on that first...

Submit a Comment Cancel reply

Your email address will not be published. Required fields are marked *

Save my name, email, and website in this browser for the next time I comment.

Submit Comment

Fiberglass Boat Repair Techniques: Quick and Effective Fixes

Understanding Fiberglass Boat Repair

With 20 years of boating experience , I’ve learned that maintaining the integrity of a fiberglass boat is essential. The repair process involves several crucial steps which require attention to detail and a systematic approach.

Firstly, assessing the damage is critical. Fiberglass boats can suffer from a range of issues, from minor scratches to major holes. As someone who’s handled many such repairs, identifying the extent of the damage dictates the repair strategy.

Here are the basic steps I follow:

- Inspect the affected area carefully to understand the depth and extent of the damage.

- Prepare the repair site by cleaning the area and removing any damaged or loose material.

- Sand the damaged area to create a rough surface for better adhesion of repair materials.

Next, selecting the materials is just as important as the repair technique itself. Epoxy resin is my go-to due to its strong adhesion and long-lasting repair qualities. Here’s a guide on basics of selecting repair materials .

Applying the repair materials involves layering fiberglass cloth and resin. The fiberglass cloth provides strength, while the resin, when cured, restores the integrity of the hull.

Remember, practice makes perfect. Working with fiberglass can be daunting, but with patience and care , a meticulously completed repair is indistinguishable from the original structure. Each repair I’ve completed over the years has reinforced my precision and skill, ensuring lasting results that keep my vessel seaworthy.

Materials and Tools Required

In my 20 years of boating experience, I’ve found that having the correct materials and tools is crucial for a successful and durable fiberglass boat repair. Knowing what to use will save you time and ensure the integrity of your boat’s structure.

Essential Materials

- Fiberglass Cloth: A foundational element for any repair, providing strength and stability to the damaged area. The quality of the cloth directly affects the repair’s resilience.

- Resin (Epoxy or Vinyl Ester): Acts as a binder for the fiberglass cloth. Epoxy resin is preferable for its strong bond and water resistance.

- Gelcoat: For aesthetic touches and to protect the repair from UV rays and water intrusion, gelcoat is applied as the outermost layer.

Recommended Tools

- Sandpaper (Various Grits): Starting with coarser grits for shaping and finer grits for finishing provides a smooth surface for repair.

- Acetone: Essential for cleaning the repair area and ensuring that contaminants do not compromise the bond.

- Brushes and Rollers: For applying resin evenly. Brushes are used for detail work and rollers for larger areas.

- Mixing Sticks and Cups: Necessary for preparing and mixing the resin before application. Accurate measurements are key to achieving the desired cure and bond strength.

Assessing the Damage

In my 20 years of boating experience, I’ve come to understand that thoroughly evaluating the type and extent of damage is critical before undertaking any repair work on a fiberglass boat.

Types of Damage

Structural Damage: This occurs to the supporting framework and influences the boat’s overall integrity. A cracked hull, for instance, compromises the vessel’s safety and needs immediate attention.

Cosmetic Damage: These are surface-level issues, such as gelcoat cracks and scratches, that do not affect the boat’s seaworthiness, but restoring the appearance is important for maintaining value.

Damage Assessment Process

Visual Inspection:

- Examine the hull and deck for any obvious signs of impact or wear.

- Look for hairline cracks, which could indicate more severe damage beneath the surface.

Tap Testing:

- Gently tap the fiberglass with a plastic hammer.

- An area that sounds hollow or different could be suffering from delamination or water intrusion.

Moisture Readings:

- Use a moisture meter to detect any water retention within the fiberglass.

- Higher readings signify potential problems with the laminate that could lead to further deterioration.

Assessing the damage with precision sets the stage for an effective and necessary repair. While smaller repairs may be DIY-friendly, significant structural damage often requires professional intervention.

Preparing for Repair

With 20 years of boating experience, I’ve learned that successful fiberglass boat repair starts with meticulous preparation. Whether you’re patching a small chip or mending a larger gash, setting the stage correctly is crucial for a long-lasting fix.

Surface Preparation

Before any resin or gelcoat is applied, the area must be clean and properly prepped. First , the damaged spot should be sanded down to remove any jagged edges and create a receptive surface for bonding. Then , washing the area with a dewaxing solvent is essential to eliminate any wax or mold release, which could compromise the repair. I’ve found that skipping this step can result in weak adhesion of the new material. Visit Repairing Fiberglass On Boats for a comprehensive guide on working with fiberglass.

Safety Measures

Fiberglass repair requires handling hazardous materials, so safety cannot be taken lightly. Always wear:

- Gloves : to protect your hands from sharp fiberglass strands and chemicals.

- Respirator mask : to avoid inhaling hazardous dust and fumes.

- Safety goggles : to shield your eyes from debris.

Moreover, maintaining a well-ventilated workspace is non-negotiable to dissipate fumes from resins and solvents. This minimizes the risk of respiratory issues and ensures a safer working environment.

Fiberglass Repair Techniques

With 20 years of hands-on boating experience, I’ve developed a deep understanding of fiberglass repair techniques that are essential for sustaining the integrity and appearance of your vessel. The key to successful repair lies in identifying the scale of the damage and employing the correct method.

Minor Repairs

Minor damages to a fiberglass boat, such as small scratches or chips, can often be repaired with simple DIY solutions.

- Materials Needed : For such repairs, you’ll need resin, hardener, fiberglass cloth, sandpaper, and a suitable gelcoat.

- Process : Begin by cleaning the area thoroughly and sanding down any rough edges. Cut the fiberglass cloth to size, mix the resin with hardener, and apply it to the affected area. Once the resin cures, sand it down to a smooth finish and apply the gelcoat for aesthetic appeal.

To illustrate, fixing a hairline crack would typically involve cleaning the area, applying a mixed resin, and laying down a piece of fiberglass cloth. After the resin has cured, I’d sand the area flush and then apply a gelcoat to match the boat’s original finish.

Major Repairs

For more significant damage, such as holes or structural weaknesses, the repair process is more complex and may require professional intervention. However, I’ve tackled such challenges myself when possible.

- Materials Needed : A list of materials includes thicker fiberglass matting or cloth, epoxy resin, a release agent, and reinforcing materials.

- Process : The area in need of repair must be ground away to remove any damaged material and to create a beveled edge where new material can be applied. Next, layers of fiberglass and resin are built up until they fill the area. It’s critical to ensure no air pockets are trapped, as this could compromise the repair’s integrity.

For example, repairing a hole in the hull involves placing a backing material behind the hole, then layering fiberglass and resin until the repair is level with the hull surface, finishing with sanding and gelcoat application. Each layer must cure properly before the next is applied, ensuring a bond as strong as the original hull.

By applying these techniques, I’ve been able to extend the lifespan of boats and maintain their value and performance.

Finishing the Repair

In my 20 years of boating experience, I’ve learned that achieving a flawless finish on a fiberglass repair is crucial for both aesthetics and the boat’s integrity. Accurate sanding, followed by meticulous buffing and polishing, are the final steps to ensure a repair blends seamlessly with the boat’s original surface.

First Pass: Coarse Grit. I start with a coarse-grit sandpaper to remove the excess cured fiberglass, working my way towards the repair margins. Care is taken not to gouge the surrounding area, which could require additional repairs.

Second Pass: Medium Grit. Once the high points are leveled, I switch to a medium-grit sandpaper. Gradual transitions are essential to avoid noticeable edges or low spots in the final product.

Final Pass: Fine Grit. To prepare for finishing, I use fine-grit sandpaper. This smoothens the surface further, removing any scratches left by coarser grains and creating a surface ready for polish.

Buffing and Polishing

Buffing Stage. After sanding, I buff the area with a rubbing compound to remove any fine scratches. This process requires a gentle touch and a steady circular motion to achieve a uniform shine without creating swirl marks.

Polishing Stage. The final step is applying a high-quality marine polish. This not only enhances the shine but also adds a protective layer against UV rays and saltwater. For the best results, I apply polish in thin layers, allowing each to dry before buffing it to a high gloss.

Gelcoat Application

In my 20 years of experience with fiberglass boats, I’ve learned that the key to a superior gelcoat finish lies in meticulous mixing and precise application methods. Ensuring the mix is correct and the application is smooth will greatly affect the longevity and appearance of the boat’s surface.

Gelcoat Mixing

Before applying gelcoat, it’s crucial to prepare the mix accurately. I always start with a clean mixing container to avoid contamination. Then, I add the gelcoat base, followed by a catalyst—typically methyl ethyl ketone peroxide (MEKP)—at a precise ratio, which is often around 2% of the volume of the gelcoat. Mix thoroughly for at least 2 minutes, ensuring a uniform color and consistency with no streaks.

Gelcoat Application Methods

When applying gelcoat, I use two main methods: brushing and spraying. Each has specific advantages, so I choose based on the repair’s nature and size.

- Ideal for small repairs or areas that are not easily accessible.

- Use a high-quality brush for an even coat and to avoid brush marks.

- Preferred for larger areas to achieve a more consistent finish.

- Requires a gelcoat spray gun and personal protective equipment to prevent inhalation of fumes.

Regardless of the method, it’s important to maintain a wet edge to avoid visible lines in the finish and apply multiple thin layers rather than one thick one to reduce the likelihood of sagging or running. After application, curing times can vary, but I usually wait a minimum of 24 hours before sanding or polishing.

Curing and Post-Cure Procedures

With two decades of handling boats, I’ve learned that meticulous attention during the curing and post-cure phases is critical for dependable fiberglass repair.

Curing Process

The curing process is when the resin hardens and bonds with the existing fiberglass. I ensure that the temperature is between 70-80 degrees Fahrenheit, as too cold or too hot can affect the cure. When I apply resin, I layer it with a catalyst, make sure the area is well-ventilated, and keep it free from dust. I use plastic film or PVA as a seal over the last resin layer to ensure a thorough cure without any tackiness.

Post-Cure Inspection

Once the resin has fully cured, my next step is a thorough inspection. I feel for imperfections such as bumps or air pockets. Any found imperfections are then addressed with gelcoat paste and allowed to cure fully. After it has cured, the patch should be sanded smoothly and polished to match the surrounding area, restoring the boat to its original condition.

Maintenance Tips

With my 20 years of boating experience, I’ve learned that regular upkeep and a proactive approach to maintenance can save you from costly repairs in the long run. Let’s dive into what I consider essential practices.

Routine Maintenance

Inspect and Clean: Every time I return from the water, I make it a practice to inspect my boat thoroughly for any signs of damage or wear, especially on the hull. I pay close attention to scratches or cracks that can worsen over time. After inspection, a thorough cleaning with soap and water helps identify any new issues that may have been obscured by dirt or debris.

- Simple Repairs: For minor scrapes that haven’t penetrated the gelcoat, I apply a marine polish to protect the area. It’s a simple but effective method to maintain the integrity of the fiberglass. However, if the damage is deeper, I make sure to apply a patch at the earliest opportunity to prevent water infiltration.

Preventive Measures

Regular Waxing: I ensure that twice a year, my boat receives a good layer of quality marine wax. This acts as a barrier against UV rays, salt, and pollutants that may harm the fiberglass. It’s an effective way to extend the boat’s aesthetic appeal and structural integrity.

- Storage and Cover: When not in use, I store my boat in a dry and shaded area. A sturdy cover is essential to protect it from the elements. I’ve learned that proactive covering minimizes the exposure to sun, moisture, and temperature fluctuations that can lead to fiberglass degradation.

Remember, a well-maintained boat ensures not just longevity but also safety and reliability. It pays to adopt a meticulous care routine.

Frequently Asked Questions

Drawing from my 20 years of boating experience, I’ve compiled a list of frequently asked questions relevant to fellow boaters looking to repair their fiberglass vessels. These inquiries cover the essentials of materials, procedures, and costs involved in keeping your boat seaworthy.

What type of epoxy is best for repairing boat hulls?

In my experience, marine-grade epoxy is the most reliable for repairing boat hulls due to its strong adhesion, resilience to water, and ability to bond with fiberglass. It’s crucial to select an epoxy that cures hard and can be sanded and painted over for a uniform finish.

What steps are involved in repairing large gelcoat damage on a boat?

Repairing large gelcoat damage typically involves cleaning the damaged area, removing any loose material, applying a gelcoat matching your boat’s current color, and then sanding it smooth. The repair area should be thoroughly dewaxed before applying new gelcoat. After curing, I always recommend polishing to restore shine and protect the repair.

How can you fix a serious gouge in a fiberglass boat’s surface?

To fix a serious gouge, I first clean the area with a dewaxing solvent, then fill the gouge with a fiberglass filler or resin. It’s important to apply the filler in layers and sand smoothly between applications. Once filled, the area should be finished with gelcoat, epoxy, or paint as necessary.

Is it possible to repair structural damage to a fiberglass boat by oneself, and what materials are needed?

Yes, it’s possible to manage structural repairs, but it requires careful planning and quality materials, including fiberglass mat, resin, and hardener. For internal structural damage, it may be necessary to use a thicker fiberglass mat for added strength when layering over the damaged area.

What is the average cost to repair a hole in a fiberglass boat?

The cost to repair a hole in a fiberglass boat can vary significantly based on the size and location of the damage, with DIY repairs typically ranging from $75 to $300 for materials. Professional repairs can escalate well into the thousands depending on the extent of the damage.

What are the most effective methods for fixing a leak in a fiberglass boat hull?

For fixing a leak in a hull, it’s effective to identify the source, dry the area, and then apply a marine-grade epoxy or fiberglass patch kit. The patched area must be adequately sealed to prevent future water ingress. In leaks where the damage is extensive or structural, professional assessment and repair are recommended for safety.

Leave a Comment Cancel reply

Save my name, email, and website in this browser for the next time I comment.

Keep in mind that we may receive commissions when you click our links and make purchases. However, this does not impact our reviews and comparisons. We try our best to keep things fair and balanced, in order to help you make the best choice for you.

As an Amazon Associate, I earn from qualifying purchases.

Vanquish Boats

500 Lewis Drive Carolina Beach, NC

+1 910-707-3599

© Vanquish Boats

- CREATE AN ACCOUNT

- Boat Cover Finder

- Bimini Top Finder

- Boat Propeller Finder

- Engine Parts Finder

- Anchor & Dock

- Watersports

- Clothing and Footwear

- Engine Parts

- Cabin and Galley

- Covers and Biminis

- Electronics

- Paint and Maintenance

- Pumps and Plumbing

- Anchor Chains & Ropes

- Boat Fenders

- Boat Mooring

- Boat Protection

- Dock Storage & Protection

- Ladders, Steps, & Platforms

- Top Sellers

- Fishing Rods

- Fishing Reels

- Fishing Rod & Reel Combos

- Fishing Tools & Tackle Boxes

- Fishing Line

- Fly Fishing

- Fishing Bait & Fishing Lures

- Fishing Rod Holders & Storage Racks

- Fish Finders, Sounders & Sonar

- Trolling Motors

- Fishing Nets

- Fishing Downriggers & Acessories

- Fishing Outriggers & Acessories

- Fishing Kayaks

- Fish Cleaning Tables

- Inflatable Rafts

- Paddle Boarding

- Paddles & Oars

- Wakeboard, Wakesurf & Ski

- Wakeboard Towers

- Tow Ropes & Handles

- Life Jackets & PFDs

- Snow Sports

- Roof Racks, Carriers, Dollies

Men's Clothing

- Accessories

Men's Footwear

- Atheltic Shoes

- Water Shoes

Women's Clothing

- Dresses & Skirts

Women's Footwear

- Fuel Systems

- Sacrificial Anodes & Zincs

- Generator Parts

- Inflatable Boats

- Propeller Parts & Accessories

- Boat Manuals

- PWC Parts & Accessories

- Fishing Boat Seats

- Offshore Boat Seats

- Ski Boat Seats

- Pontoon Boat Seats & Furniture

- Boat Seat Pedestals & Hardware

- Boat Seats by Manufacturer

- Boat Tables & Hardware

- Boat Seat Covers

- Boat Seat Vinyl

- Floating Boat Cushions

- Barbeque Grills

- Boat Drink Holders

- Cabin Accessories & Hardware

- Boat Ventilation

- Interior & Cabin Lighting

- Marine Teak Products

- Carbon Monoxide & Smoke Detectors

- Binoculars & Telescopes

Boat Bimini Tops

- Bimini Top Accessories

- Pontoon Bimini Tops

- Other Biminis

- RV & Trailer Covers

- Boat Shrink Wrap & Accessories

- Boat Shelters

Boat Covers

- Boat Cover Accessories

- Boat Lift Canopy Covers

- Other Covers

- Boat Wiring & Cable

- Marine Batteries & Accessories

- Marine DC Power Plugs & Sockets

- Marine Electrical Meters

- Boat Lights

- Marine Electrical Panels & Circuit Breakers

- Power Packs & Jump Starters

- Marine Solar Power Accessories

- Marine Electrical Terminals

- Marine Fuse Blocks & Terminal Blocks

- Marine Switches

- Shore Power & AC Distribution

- Marine Audio & Video

- GPS Chartplotters & Accessories

- Electronic Navigation Charts & Software

- Digital Instruments

- Display Mounts

- VHF Radios & Communication

- Marine Radar

- Auto Pilot Systems

- Action Cameras

- Fiberglass & Epoxy Boat Repair

- Boat Paint & Varnish

- Marine Adhesives, Sealant, & Caulking

- Marine Engine Maintenance

- Boat Cleaners & Waxes

- Boat Cleaning Supplies

- Fresh Water Boat Systems

- Bilge Pumps

- Marine Plumbing Parts

- Wash Down Pumps

- Livewell Aerator Pumps & Live Bait Wells

- Toilet & Waste Pumps

- Marine Pump Replacement Parts

- Tires, Rims, & Hub Kits

- Boat Trailer Winches

- Boat Motor Supports & Transom Savers

- Boat Trailer Guides & Rollers

- Boat Trailer Fenders

- Boat Trailer Lights

- Boat Trailer Hardware

- Boat Trailer Jacks

- Boat Trailer Brakes & Axles

- Boat Trailer Tie Downs

- Couplers, Mounts, Hitches, & Locks

- Boat Deck Harware

- Marine Nuts, Bolts, & Screws

- Boat Handles, Pulls, & Rings

- Prop Nut Kits & Hardware

- Boat Cabin Hardware

- Marine Fasteners

- Boat Windshield Parts

- Boat Tubing & Rails

- Boat Mirrors

- Marine Tools & Tool Kits

- Boat Lettering

- Women's Clothing Deals

- Men's Clothing Deals

- Fishing Deals

- Anchor & Dock Deals

- Electrical Deals

- Electronics Deals

- Paint & Maintenance Deals

- Pumps & Plumbing Deals

- Boat Seats Deals

- Trailering Deals

- Camping & RV Deals

- Dealer Login

- Forums Login

- Search forums

- The iboats forum moderators are excited to announce that at this time it appears the iboats forums posting pictures function is working once again. Though we cannot promise for how long, we're hoping for indefinitely.

- Boat Repair and Restoration

- Boat Restoration, Building, and Hull Repair

How to fix or repair a keel that has exposed or pitted fiberglass

- Thread starter Sailor98277

- Start date Aug 28, 2013

Sailor98277

- Aug 28, 2013

How would I go about fixing a keel that has its gel coat missing from being grounded on a beach? Would you first fill in the divits with small pieces of fiberglass and resin, then rough sand and put on gel coat or would you just fill in the divits with gel coat? I will take pics tomorrow and post them here to give you a better idea of what I am refering to. Thanks all for your help. Vr, Michael

- Aug 29, 2013

Re: How to fix or repair a keel that has exposed or pitted fiberglass Quite honestly, if it is still watertight and you intend to continue to beach, I would "repair" by installing a keelshield or keelguard strip. I abused the heck out of a previous boat for one season by beaching it multiple times. by the end of the season the gelcoat had worn completely down to where you could see the cloth. I just sanded everything smooth and installed the keelguard over the worn gelcoat. When I installed the keelguard I sealed it all around the edge with 5200, and for two more seasons of boating/beaching I never had an issue. Keelguard looked practically brand new when I sold the boat at the end of last season. When I purchased my new boat, the first thing I did was install a keelguard. Good luck Eric

Woodonglass

Supreme mariner.

Re: How to fix or repair a keel that has exposed or pitted fiberglass Yup ^^^ sound advice. If no more beaching will occur then mix up some thickened resin using resin, cabosil, and some copped up CSM to fill the divots then sand and shape. Use some 3M premium filler for final fairing, then us a Preval Sprayer to spray on 3-4 coats of Gelcoat. Sand and Polish. DONE

Re: How to fix or repair a keel that has exposed or pitted fiberglass Thank you eavega for the information. I had asked this very question to some guys over at West Marine about using a keel guard to fix this and was told that it would not stop the water from leaking through the keel into the bottom of the boat. This was because when water is in contact for an extended period of time, water will seep through the fiberglass and into the inside of the boat. I do not know if that is true or not, hence my reason for asking you experts here. Thank you again for your help. I will be doing what you recommended. Vr, Michael

Re: How to fix or repair a keel that has exposed or pitted fiberglass Thank you woodonglass for your help as well. I will be sure to do as you said and put the keel guard over the patch. It will take me a bit of time as I still have to figure out a way to get the boat raised up so that I can work on the bottom of it and the trailer out from under it. Thanks again. Vr, Michael

Re: How to fix or repair a keel that has exposed or pitted fiberglass If the keel is damaged bad enuf to expose the glass and water can penetrate then it for sure needs to be repaired prior to the installation of a keel guard.

- Aug 30, 2013

Re: How to fix or repair a keel that has exposed or pitted fiberglass Yup, I'd be grinding that down, filling all major gouges and laying 2-3 layers of 1.5oz CSM over all of it and then 3-4 coats of gelcoat with a Preval Sprayer. If you are going to continue beaching her then by all means a Keel guard is in your future!!! What kind of boat is this?

Re: How to fix or repair a keel that has exposed or pitted fiberglass Thank you Woodonglass, I have never had this boat in the water. My brother-in-law convinced my wife it was a great boat for us to use on Puget Sound to go fishing and crabbing in. The floor was soft so that when you stepped into it you felt like you were gonna fall through, the motor wont start even though it has good compression, and the keel is all torn up from beaching. I won't be beaching the boat when completed, but I will be installing a keel guard to protect it none the less. If I remember right, it is an 18' 1967 Las Vegas Sierra Tri-Hull. I have done so many searches for information on this particular boat it is not funny, but have come up snake eyes. I planned on picking up some CSM tomorrow so that I can use it to put down the initial layer of glass and resin on the floor joints then cover that over with woven mat. I am using West Marine Polyester Boaters Resin that I bought in (2) 1 gallon cans. I believe that should be enough to do the joints in the floor and sides where the floor meets the gunnals. I hope that it will also be enough to do one layer on the floor of just resin but we will see as I also have to buy the pour in foam yet this coming Sept. I would love to have the floor all done before the rains hit here in a few weeks. Vr, Michael

Petty Officer 1st Class

- Aug 31, 2013

Re: How to fix or repair a keel that has exposed or pitted fiberglass Did you pay much for the boat? The reason that I ask is that soft floors are quite often indicative of other structural issues, namely wet or rotted stringers and bulkheads. Once you get the floor up, you are likely find that you've opened up a major can of worms. If that happens then you have to decide whether to do a half assed repair, go all the way on a restoration, or scrap it and try to recoup your money. I'm not trying to sound negative, just being realistic as I stumbled into the same situation and now have 36 days straight on my renovation.

Re: How to fix or repair a keel that has exposed or pitted fiberglass Hello Bakerjw and grub1grub2, I paid $500 for the boat which included a 80 hp merc outboard that would not run, though the guy said it did. My brother-in-law convinced my wife like I had said and there was nothing I could really do about it as she had her head set on getting it. I pulled up the soft floor, took out close to 800 lbs of water logged foam, and found that one cross member was rotted out. The long stringers seemed solid at the back end of the boat but I had no way of taking the cap off the boat so I could pull out all the stringers and start from scratch. I intend to put 2 lb flotation foam back in which will give it some structural support as well as the obvious floatation requirements. I'm not sure if I will keep the boat or not but I will fix it up all the same as is. It is at best just a temp boat that when I have more money, I will buy a decent boat (like this will ever happen). However, it is only for doing some basic salmon fishing in pretty much calm waters, and wont be taken out into the heavy chop. I still need to fix the motor and find a way to lift the boat up so I can fix the keel with the recommendations from above. It's not the boat I wanted to get but the wife would not let me spend more even though this one will cost me about $1000 just to get it back to seaworthy status and that does not include a functioning motor. Oh well, what is a guy to do? I like being on and around the water so I will make do. When I have the floor done or further along with its first coat of glass, I will take a pic of it. Vr, Michael

Re: How to fix or repair a keel that has exposed or pitted fiberglass Thanks Woodonglass, I have checked part of the stringers where the foam was the wettest and the stringers were ok there, however that does not mean the whole of them are fine. As for the transom, it is solid. The motor on it will not be the one staying on it. the control arm that turns the motor left and right comes into contact with the left side of the troff in the top. I will most likely down grade the motor if I keep the boat to about a 50 hp. I have a neighbor who wants to buy the boat for $500 or so to include the trailer. I have been giving that serious thought. I do not have the funds to pull the whole bottom apart and redo as necessary being I am on such a limited income. However others might and this guy would most definately have the cash. Then again, who knows. Thanks for the tips and information as it is greatly appreciated... it is also a very good learning experience. Vr, Michael

Re: How to fix or repair a keel that has exposed or pitted fiberglass Did you actually drill into the stringers and the transom to inspect the shavings or just do an outward visual inspection and some tapping around with a hammer and such??

- Sep 2, 2013

Re: How to fix or repair a keel that has exposed or pitted fiberglass It was a drill as I made a pilot hole when I put the new cross member in toward the rear of the stringers. When I screwed the floor down, the screws again had pilot holes to follow, and the ones at the back were or seemed fine, but the others might have been a bit to easy going in now that I think of it.

Petty Officer 3rd Class

Re: How to fix or repair a keel that has exposed or pitted fiberglass repair with a kevlar reinforced epoxy paste - you can use glass with it , but sounds like you don't need to google wet dry 700 epoxy Paul Oman - MS. MBA A.K.A. “Professor E. Poxy” Internet Epoxy Confederation (IEC) Homepage epoxies since 1994 Member: NACE (National Assoc. of Corrosion Engineers) -- SSPC (Soc. of Protective Coatings)

Sailboat Bottom Cleaning - Complete DIY Guide

Sailboat bottom cleaning is an essential part of regular hull maintenance, but it doesn't have to be a serious hassle.

Sailboat bottom cleaning can be done in or out of the water. The most important tools include marine gloves, various scrapers, and brushes. A coat of high-quality bottom paint can reduce cleaning intervals and marine buildup.

In this article, we'll go over how to clean a sailboat bottom in or out of the water. We'll cover the best methods and give you a rundown of all the tools you'll need to do the job. Additionally, we'll go over the importance of bottom paint and the best methods to reduce the headache of hull maintenance.

We sourced the information used in this article from sailors with bottom cleaning experience. Additionally, we gathered facts about hull cleaning from reliable sailboat maintenance guides.

Table of contents

What Happens to a Sailboat Hull in the Water?

A clean sailboat hull doesn't stay clean for long, but any skipper can tell the difference between a freshly scraped hull and a neglected bottom. As soon as you drop the boat in the water, marine gunk starts to slowly accumulate on all submerged surfaces.

First, bacteria and microorganisms start to accumulate and build up a slime. Anti-growth paints slow this buildup, but it eventually overpowers the paint. At this stage, a simple hosing down could do the trick. But over time, the slime forms a protective layer onto which larger and more sensitive organisms can begin to thrive.

Within a month or two, even the most well-maintained sailboat bottom will start to accumulate your local species of barnacles, mussels, and sharp sea trash. The bottom is now its own micro-ecosystem.

Soon, all of that annoying and injurious sea garbage will begin clogging intakes, exhaust ports, drains, and jamming up rudder components.

How Often Should You Clean a Sailboat Bottom?

Bottom cleaning should be done regularly, regardless of how you use your boat. That said, it's a more urgent task for some sailors who get underway often.

People who cruise regularly or over long distances should clean the bottom once every month or two, whereas the twice-per-year sailor can get away with a biannual cleaning.

The Importance of Sailboat Bottom Paint

Bottom paint is specially formulated to slow or stop the growth of marine life. Traditionally, 'red lead' paint was used to inhibit barnacles and other gunk from taking refuge on the hull. Red lead is just that—red paint with high lead content. Lead is poisonous to marine life, and it's extremely effective at preserving the bottom.

Red lead comes with hazards, and it's difficult to obtain in some areas. Today, its use is limited to wooden boats and historical restorations.

In the 21st century, numerous less toxic paint alternatives exist. They're costly, but modern bottom paints can last for years without significant repairs.

It's essential to keep your hull covered in a strong layer of bottom paint, regardless of the age or condition of the vessel. High-quality bottom paint can drastically reduce hull growth and cleaning intervals, which is why it's a key priority for long-range cruising skippers.

Why is Bottom Cleaning Necessary?

Bottom cleaning is absolutely necessary if you want your boat to work well and last a long time. Marine life grows rapidly on sailboat hulls, and it can add weight to your hull and cause damage.

The biggest issue with marine growth is drag, as it adds a rough texture to an otherwise smooth sailboat hull and slows it down. Additionally, marine life can seize rudders and clog seacocks.

What Happens if You Don't Clean the Hull?